High-strength fly ash brick and preparation method thereof

A fly ash brick and high-strength technology, which is applied in the field of high-strength fly ash brick and its preparation, can solve the problem of indurability, low activation utilization rate of fly ash, poor cementitiousness and freeze-thaw resistance of fly ash And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

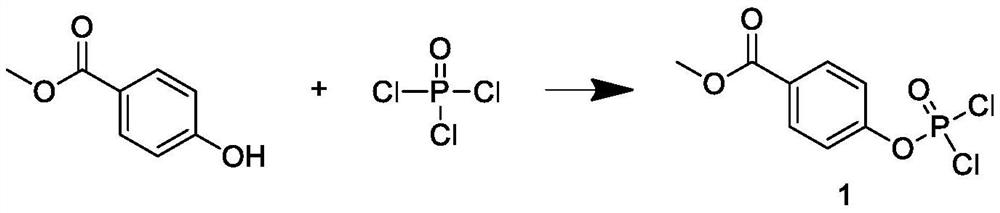

[0033] Preparation of flame retardant components:

[0034] Step S11, mixing methyl hydroxybenzoate and tetrahydrofuran, adding phosphorus oxychloride at 0°C, then adding pyridine, and stirring for 35 minutes to obtain intermediate 1;

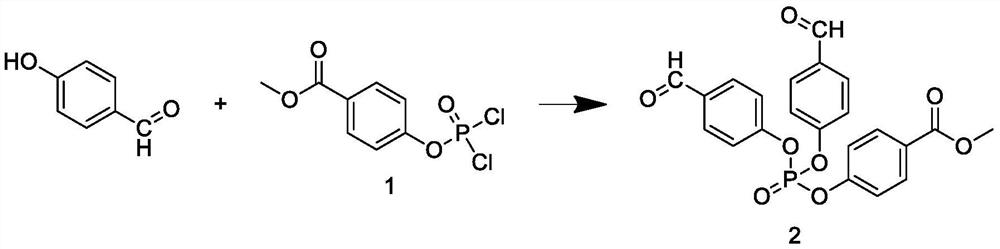

[0035] Step S12, mix p-hydroxybenzaldehyde, dichloromethane and triethylamine, pass through nitrogen to protect and stir to cool down to 0°C, then add intermediate 1, stir and react for 7h, after the reaction, the obtained reactant is deionized Wash with water three times, then adjust the pH value to 9 with sodium hydroxide, wash with deionized water until the washing liquid is neutral, and then dry with anhydrous sodium sulfate. After drying, concentrate under reduced pressure to remove the solvent to obtain the intermediate 2;

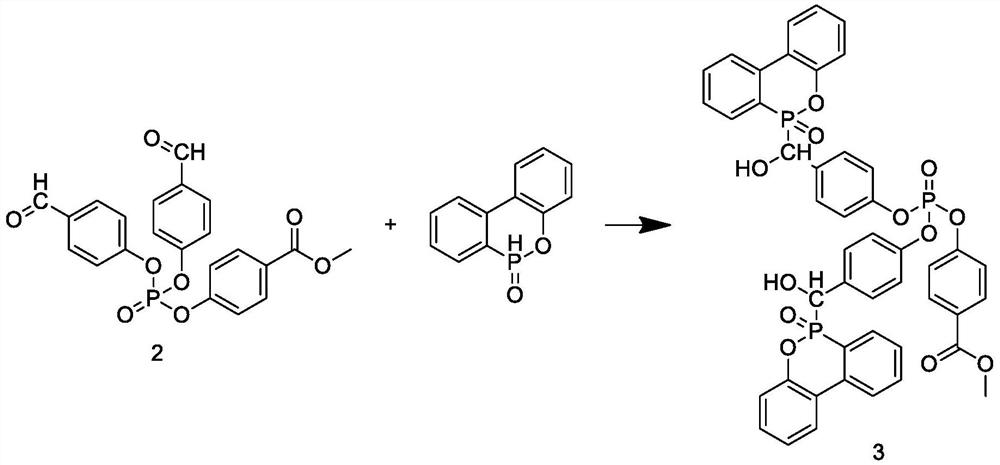

[0036] Step S13, under the condition of nitrogen protection, mix 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and toluene, heat to reflux, then add intermediate 2, after the addition, The reaction was continued...

Embodiment 2

[0041] Prepare enhancer:

[0042] Mix brucite fiber and absolute ethanol to prepare a slurry, add polyphosphoric acid ethanol solution to the slurry, heat and reflux for 10 minutes, then add flame retardant components while stirring, continue to react for 2 hours, then filter the reaction mixture, filter The cake was washed with absolute ethanol, and dried under vacuum at 50° C. for 6 hours after washing to obtain the enhancer.

[0043]Among them, the dosage ratio of brucite fiber and absolute ethanol in the slurry is 1g:20mL; the ethanol solution of polyphosphoric acid is a mixture of polyphosphoric acid and absolute ethanol according to 1g:5mL; the ethanol solution of slurry, polyphosphoric acid and flame retardant The dosage ratio of the components is 20mL: 4mL: 0.2g, and the flame retardant component is prepared in Example 1.

Embodiment 3

[0045] Prepare enhancer:

[0046] Mix brucite fiber and absolute ethanol to prepare a slurry, add polyphosphoric acid ethanol solution to the slurry, heat and reflux for 10 minutes, then add flame retardant components while stirring, continue to react for 2 hours, then filter the reaction mixture, filter The cake was washed with absolute ethanol, and dried under vacuum at 50°C for 6 hours after washing to obtain the enhancer.

[0047] Among them, the dosage ratio of brucite fiber and absolute ethanol in the slurry is 1g:20mL; the ethanol solution of polyphosphoric acid is a mixture of polyphosphoric acid and absolute ethanol according to 1g:5mL; the ethanol solution of slurry, polyphosphoric acid and flame retardant The dosage ratio of the components is 20mL: 3mL: 0.25g, and the flame retardant component is prepared in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com