Hyperbranched polymer, preparation method and application thereof, and washing product

A technology of hyperbranched polymer and polymerization reaction, which is applied in chemical instruments and methods, detergent compositions, detergent compounding agents, etc. It can solve the problems of high equipment investment, complicated process, and long time-consuming, so as to reduce production costs , Low cost of raw materials, reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

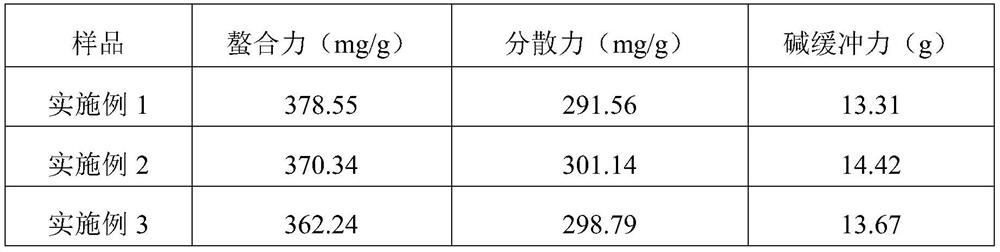

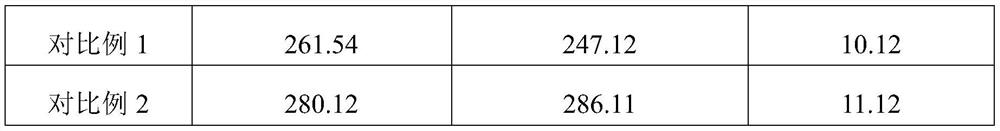

Examples

Embodiment 1

[0051] S1: Preparation of hyperbranched functional monomer A

[0052]Introduce nitrogen into the three-necked flask for 5 minutes, put 80g of methyl acrylate, 70g of trimethylolpropane and 60g of allylamine into the three-necked flask, add 1g of p-toluenesulfonic acid as a catalyst, and stir magnetically at 80°C Reflux reaction for 3 hours, after purification and filtration, the hyperbranched functional monomer A was obtained.

[0053] S2: Preparation of hyperbranched polymers

[0054] Add the hyperbranched functional monomer A prepared in S1, 90g deionized water, and 10g allyl alcohol polyoxyethylene ether into the reaction kettle, stir and raise the temperature to 70-80°C, and add 170g of acrylic acid and 50g of sodium persulfate dropwise at the same time The aqueous solution (mass fraction is 2%) and 50g sodium bisulfite aqueous solution (mass fraction is 5%), the dropwise addition time is 3h, after the dropwise addition is completed, the constant temperature reaction is c...

Embodiment 2

[0056] S1: Preparation of hyperbranched functional monomer A

[0057] S1 is the same as in Example 1.

[0058] S2: Preparation of hyperbranched polymers

[0059] Add the hyperbranched functional monomer A prepared in S1, 90g of deionized water, and 10g of prenol polyoxyethylene ether into the reaction kettle, stir and heat up to 70-80°C, and dropwise add 170g of acrylic acid and 50g of persulfuric acid Potassium aqueous solution (mass fraction is 2%) and 50g sodium metabisulfite aqueous solution (mass fraction is 5%), the dropwise addition time is 2h, after the dropwise addition is completed, the constant temperature reaction is carried out for 2h. After the reaction is finished, the temperature is lowered to about 50° C., neutralized to neutral with potassium hydroxide solution, and a hyperbranched polymer is obtained.

Embodiment 3

[0061] S1: Preparation of hyperbranched functional monomer A

[0062] S1 is the same as in Example 1.

[0063] S2: Preparation of hyperbranched polymers

[0064] Add the hyperbranched functional monomer A prepared in S1, 90g deionized water, and 10g methallyl polyoxyethylene ether into the reaction kettle, stir and raise the temperature to 70-80°C, and simultaneously add 170g of acrylic acid, 50g of Ammonium sulfate aqueous solution (2% by mass fraction) and 50 g sodium metabisulfite aqueous solution (5% by mass fraction) were added dropwise for 3 hours, and were reacted at constant temperature for 1 hour after the addition was completed. After the reaction, the temperature was lowered to about 50°C, and neutralized with liquid ammonia to obtain a hyperbranched polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com