Application of Fe3O4 nano particles to improvement of fermentation performance of saccharomyces cerevisiae

A nanoparticle and Saccharomyces cerevisiae technology, applied in the field of bioengineering, can solve problems such as poor ethanol tolerance, achieve the effects of improving tolerance, accelerating oxidation decomposition, and improving catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

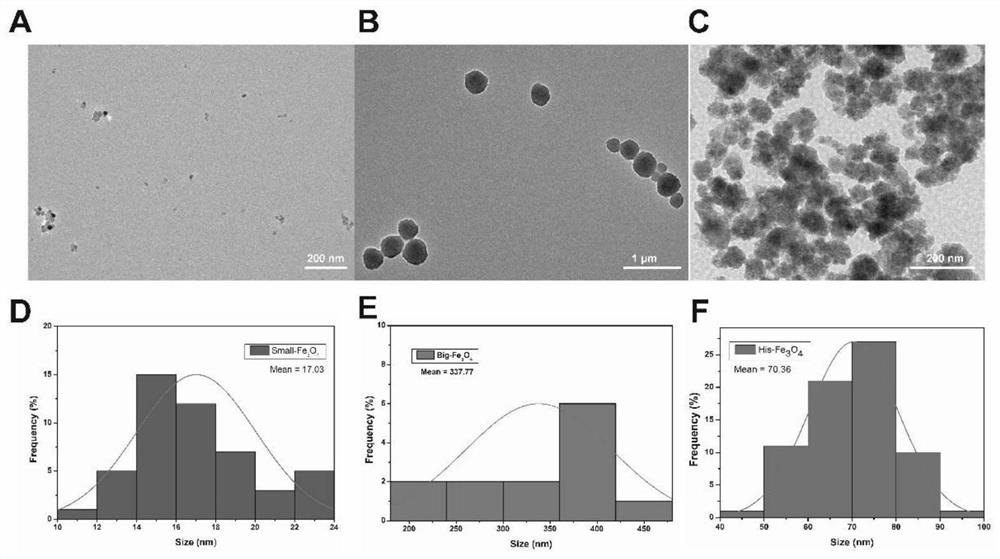

[0036] The aforementioned Big-Fe 3 o 4 The preparation method is: according to the mass ratio of ferric chloride: trisodium citrate: ethylene glycol: sodium acetate=13:4:440:24, after ferric chloride and trisodium citrate are completely dissolved in ethylene glycol , then add sodium acetate and stir vigorously until the mixture is uniform, then transfer the mixture to an autoclave, heat at 200°C for 10h, wash the product with ethanol and dry it to obtain Big-Fe 3 o 4 . Among them, sodium acetate plays the role of electrostatic balance and coordinating reducing agent in the whole system. After other raw materials are mixed, adding solid sodium acetate can make the concentration of reactants more uniform.

[0037]In order to obtain better experimental results, it is preferred that the vigorous stirring time is 30-40 minutes, the autoclave is a Teflon-lined stainless steel autoclave, and the drying temperature is 55-65°C.

[0038] The above His-Fe 3 o 4 The preparation meth...

Embodiment 1

[0051] (3) Embodiment 1 cultivation experiment

[0052] The above-prepared Small-Fe 3 o 4 , Big-Fe 3 o 4 , His-Fe 3 o 4 Take 400 μL of each stock solution and add them to 100mL LYPD medium (the main components of the medium are: 2g peptone, 2g glucose, 1g yeast extract, 2g agar) as the three experimental groups, and another 100mLYPD medium without adding Fe 3 o 4 NPs were used as the control group (NC), and then 8% (v / v) ethanol and 5% (v / v) Saccharomyces cerevisiae were added to the experimental group and the control group respectively, and cultured for 24h (30°C, 120rpm).

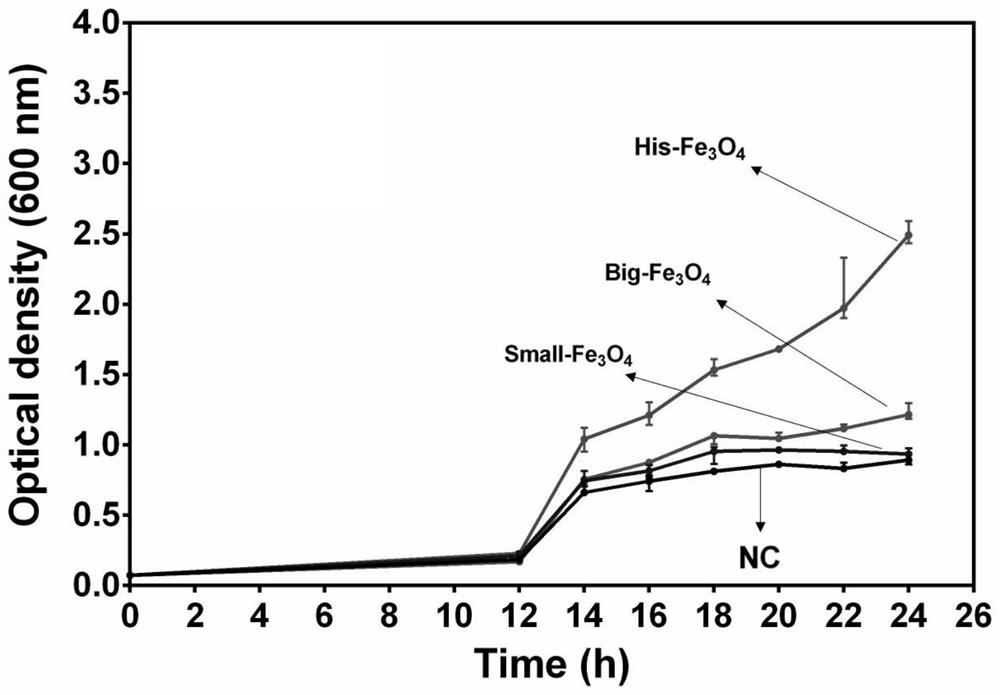

[0053] Result detection: In the process of co-cultivation, the optical density of Saccharomyces cerevisiae in the culture solution was detected at 600nm by using a UV-visible spectrophotometer, and the results were as follows: image 3 shown by image 3 It can be seen that the addition of His-Fe in the experimental group 3 o 4 The yeast optical density of the group was significantly higher than...

Embodiment 2

[0054] (4) Example 2 drop plate experiment

[0055] A. Small-Fe 3 o 4 , Big-Fe 3 o 4 , His-Fe 3 o 4 Take 400 μL of each stock solution, add it to 100mL LYPD solid medium (2% agar) as the experimental group, and take another 100mLYPD solid medium without adding Fe 3 o 4 NPs were used as the control group (NC), and then 12% (v / v) ethanol was added to the experimental group and the control group, respectively, for standby;

[0056] B. Small-Fe 3 o 4 , Big-Fe 3 o 4 , His-Fe 3 o 4 Take 400 μL of each stock solution, add it to 100mL LYPD solid medium (2% agar) as the experimental group, and take another 100mLYPD solid medium without adding Fe 3 o 4 NPs were used as the control group (NC), and then 16% (v / v) ethanol was added to the experimental group and the control group, respectively, for later use;

[0057] C. Drop plate test: dilute the yeast concentration to 10 0 、10 -1 、10 -2 、10 -3 and 10 -4 , pipette 10 μL dropwise into the solid medium prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com