High-drug-loading degradable alginate sulfate vascular embolization microspheres and preparation method and application thereof

An alginic acid sulfate, embolizing microsphere technology, applied in the application, medical science, surgery and other directions, can solve the problems of non-degradable pharmaceutical raw materials, difficult to balance the embolization/degradation function, and the degradation speed is too fast, and achieve excellent biocompatibility and degradability, improving drug loading performance, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of highly drug-loaded degradable alginate sulfate vascular embolism microspheres, comprising the following steps:

[0042] (1) Water phase preparation: add 3.0 g of alginic acid sulfate into 15 mL of deionized water, dissolve evenly, adjust the pH to 11.0 with 2 mol / L NaOH solution, and set aside.

[0043] (2) Oil phase preparation: Add 4.5g Span60 to 300mL soybean oil, stir at 85°C until Span60 is completely dissolved, and set aside.

[0044] (3) Preparation of alginate sulfate microspheres: Add the prepared water phase to the oil phase at a speed of 10mL / min, and the stirring speed is 500r / min. After adding the water phase, add 9mL epichlorohydrin, React at 70°C for 4 hours; screen out the microspheres, wash with petroleum ether, ethyl acetate, and absolute ethanol three times, and vacuum-dry at 50°C to obtain alginate sulfate microspheres.

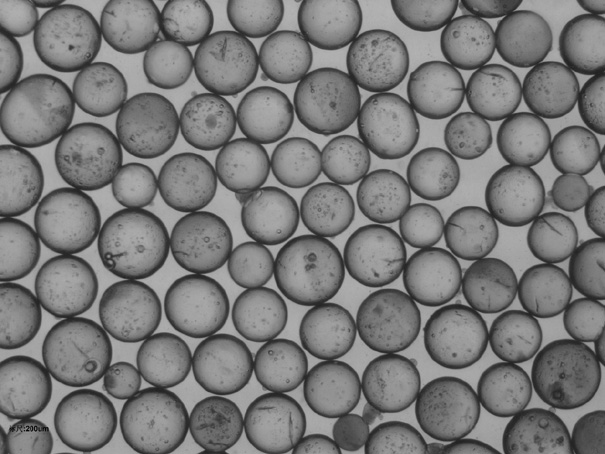

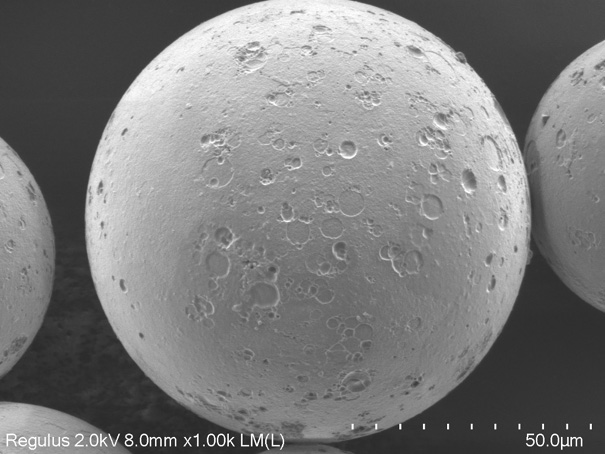

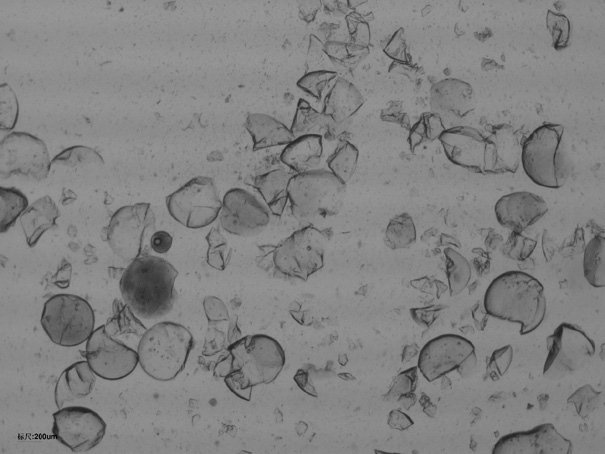

[0045] Such as figure 1 As shown, the alginate sulfate microspheres prepared by the present invention ha...

Embodiment 2

[0054] A preparation method of highly drug-loaded degradable alginate sulfate vascular embolism microspheres, comprising the following steps:

[0055] (1) Water phase preparation: Add 4.5g of alginic acid sulfate into 15mL of deionized water, dissolve evenly, adjust the pH to 11.0 with 2mol / L NaOH solution, and set aside.

[0056] (2) Preparation of oil phase: Add 4.5 g of Span60 and 0.5 g of Tween 60 to 300 mL of soybean oil, stir at 85 °C until the emulsifier is completely dissolved, and set aside.

[0057] (3) Preparation of alginic acid sulfate microspheres: Add the prepared water phase to the oil phase at a speed of 10mL / min, and the stirring speed is 500r / min. After adding the water phase, add 18mL epichlorohydrin, React at 85°C for 4 hours; sieve out the microspheres, wash with petroleum ether, ethyl acetate, and absolute ethanol three times, and vacuum-dry at 50°C to obtain alginate sulfate microspheres.

[0058] (4) Dissolve the drug in pure water, put the alginate s...

Embodiment 3

[0064] A preparation method of highly drug-loaded degradable alginate sulfate vascular embolism microspheres, comprising the following steps:

[0065] (1) Water phase preparation: Add 1.5g of alginic acid sulfate into 15mL of deionized water, dissolve evenly, adjust the pH to 8.0 with 2mol / L NaOH solution, and set aside.

[0066] (2) Oil phase preparation: Add 0.3 g of Span80 to 300 mL of sunflower oil, stir at 60°C until the emulsifier is completely dissolved, and set aside.

[0067] (3) Preparation of alginic acid sulfate microspheres: Add the prepared water phase to the oil phase at a rate of 0.1mL / min, where the stirring speed is 300r / min, and add 1.5mL epoxy chloride after the water phase is added Propane, reacted at 60°C for 2 hours; sieved the microspheres, washed them repeatedly with petroleum ether, ethyl acetate, and absolute ethanol respectively, and dried them in vacuum at 60°C to obtain alginic acid sulfate microspheres.

[0068] (4) Dissolve the drug in pure wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com