A kind of preparation method of gold single-atom catalyst

A catalyst and atomic technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of small load capacity and low production efficiency, so as to increase the load capacity, increase the atomic load capacity, The effect of excellent electronic characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

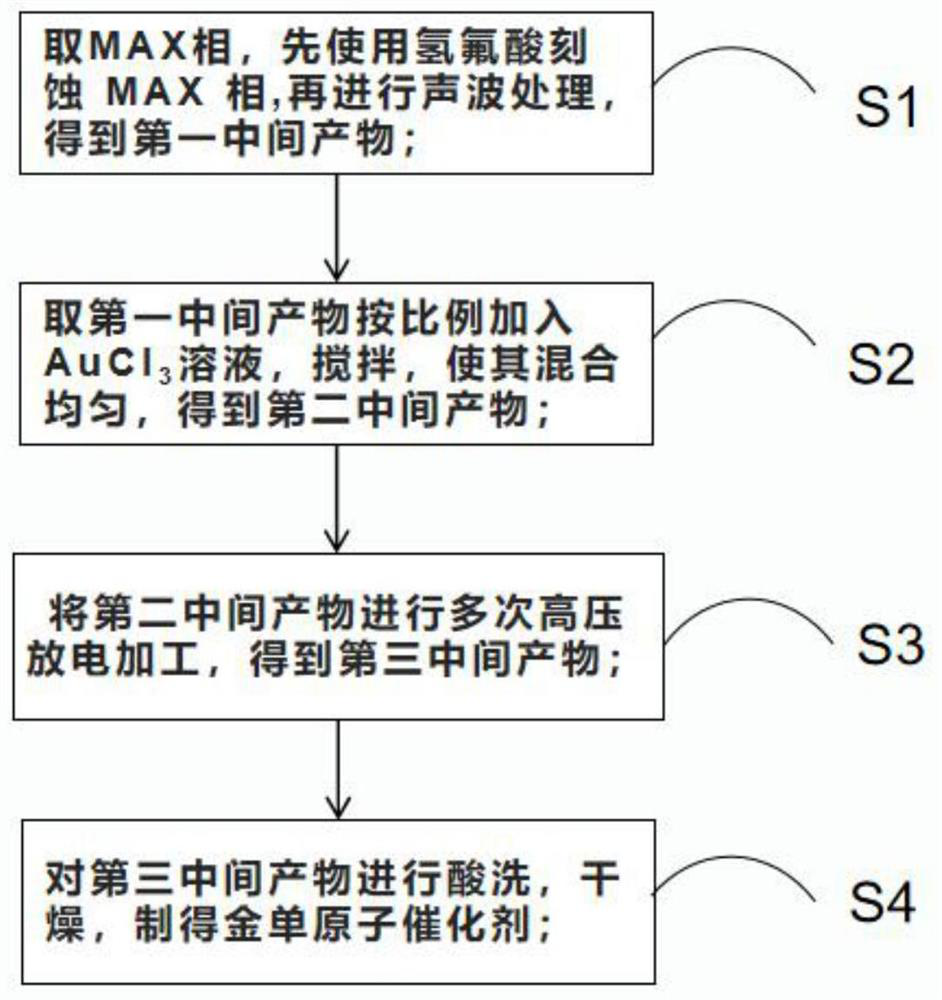

[0022] A preparation method of a gold single-atom catalyst, comprising the following steps:

[0023] S1: Take the MAX phase, first use hydrofluoric acid to etch the MAX phase, and then perform sonication to obtain the first intermediate product, which is a two-dimensional MXene;

[0024] S2: Take the first intermediate product and add it to AuCl 3 solution, stir evenly to obtain the second intermediate product;

[0025] S3: subjecting the second intermediate product to high-voltage discharge machining for multiple times to obtain a third intermediate product;

[0026] S4: pickling and drying the third intermediate product to obtain a gold single-atom catalyst.

[0027] Gold single-atom catalysts have the advantages of high catalytic efficiency, good stability, and high utilization rate, and their excellent catalytic performance can be attributed to the existence of a single gold atom. The catalytic activity of the catalyst has a significant influence. Gold single-atom cata...

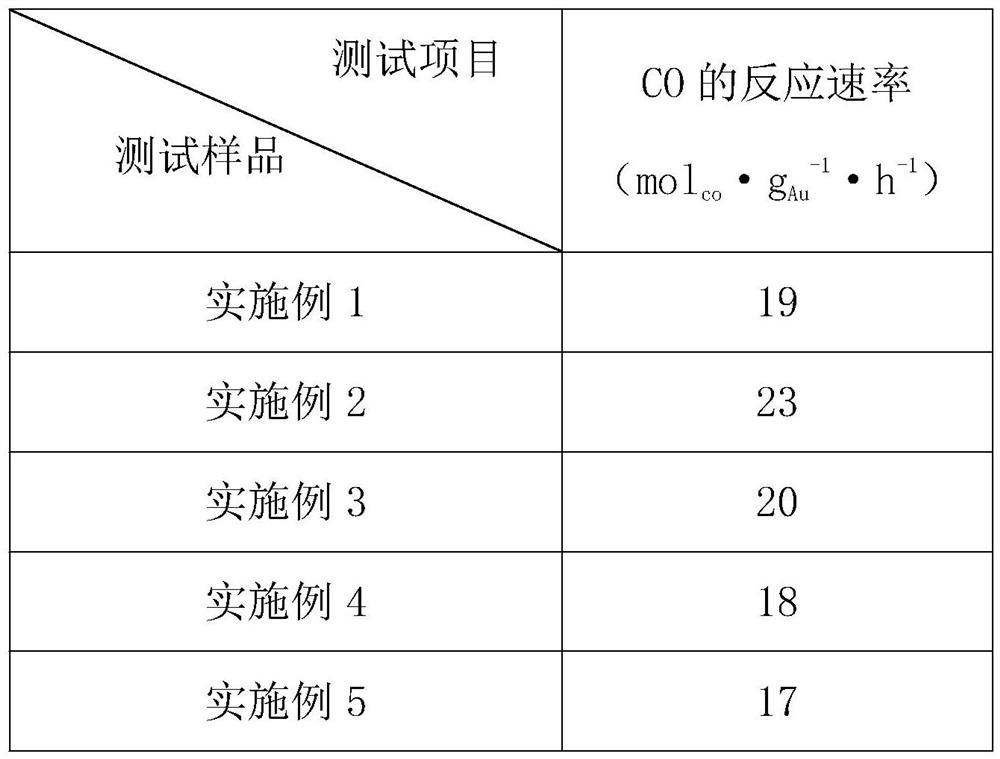

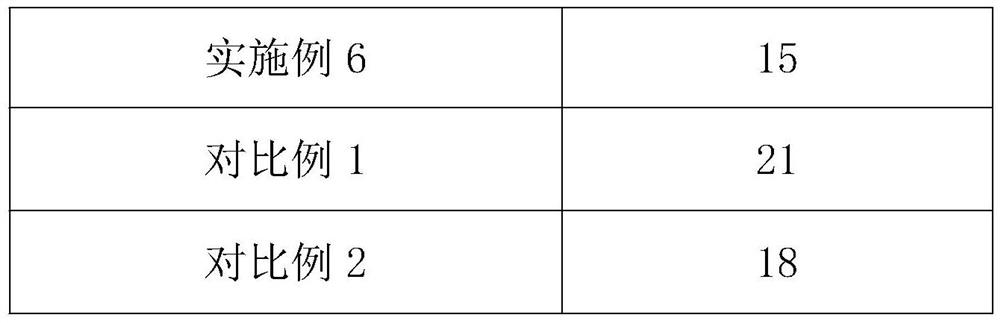

Embodiment 1

[0049] S1: Take the MAX phase, first use hydrofluoric acid to etch the MAX phase, and then perform sonication, the sonication time is 10 minutes, and obtain the first intermediate product, in which the MAX phase is Ti 3 AlC 2 ;

[0050] S2: Take the first intermediate product and add it to AuCl 3 solution, stirred to make it evenly mixed to obtain the second intermediate product, in which AuCl 3 The concentration of the solution is 1mol / L, the first intermediate product and AuCl 3 The mass ratio of the solution is 10:1;

[0051] S3: subjecting the second intermediate product to high-voltage discharge processing, the discharge voltage is 220v, the discharge capacity is 216mF, and the number of discharges is 5 times to obtain the third intermediate product;

[0052] S4: pickling the third intermediate product with 2 mol / L dilute hydrochloric acid, and drying the acid-washed third intermediate product in a vacuum oven to constant weight to obtain a gold single-atom catalyst. ...

Embodiment 2

[0054] S1: Take the MAX phase, first use hydrofluoric acid to etch the MAX phase, and then perform sonication, the sonication time is 10 minutes, and obtain the first intermediate product, in which the MAX phase is Ti 3 AlC 2 ;

[0055] S2: Take the first intermediate product and add it to AuCl 3 solution, stirred to make it evenly mixed to obtain the second intermediate product, in which AuCl 3 The concentration of the solution is 1mol / L, the first intermediate product and AuCl 3 The mass ratio of the solution is 12:1;

[0056] S3: subjecting the second intermediate product to high-voltage discharge processing, the discharge voltage is 220v, the discharge capacity is 216mF, and the number of discharges is 5 times to obtain the third intermediate product;

[0057] S4: pickling the third intermediate product with 2 mol / L dilute hydrochloric acid, and drying the acid-washed third intermediate product in a vacuum oven to constant weight to obtain a gold single-atom catalyst. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com