Quartz fiber/modified cyanate ester composite material as well as preparation method and application thereof

A composite material and quartz fiber technology, applied in the direction of the radiation unit cover, can solve the problems of poor heat resistance, high cross-linking density, and unsatisfactory radome, etc., and achieve the effect of strong operability and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

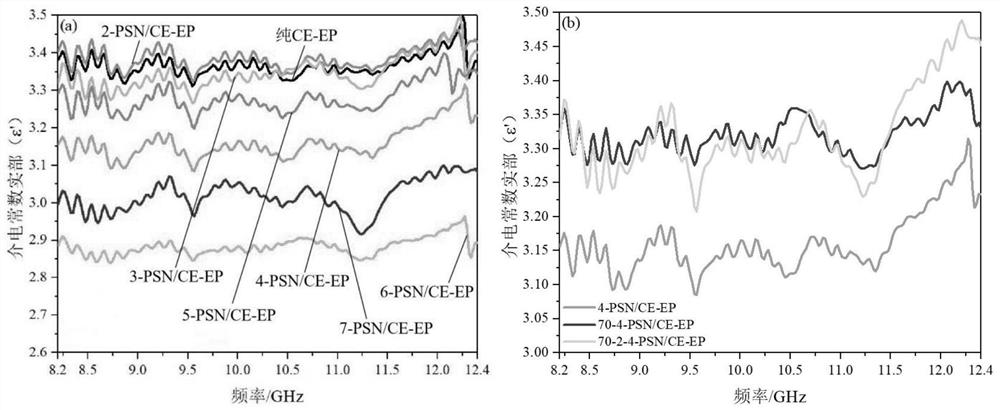

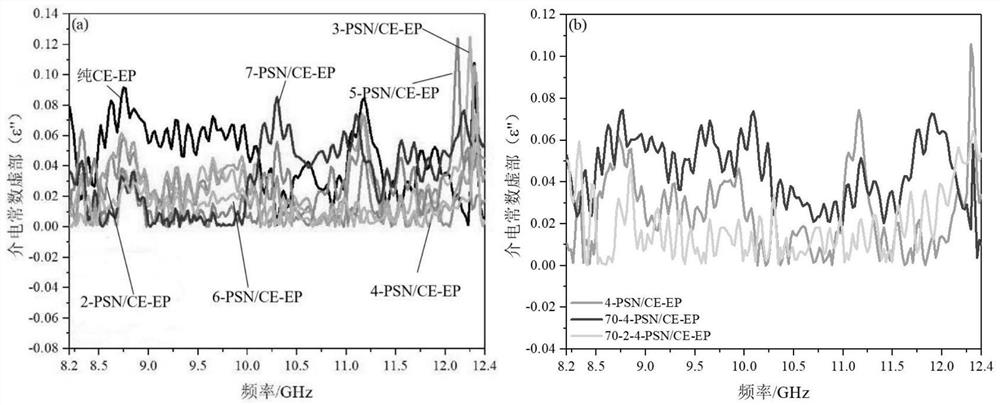

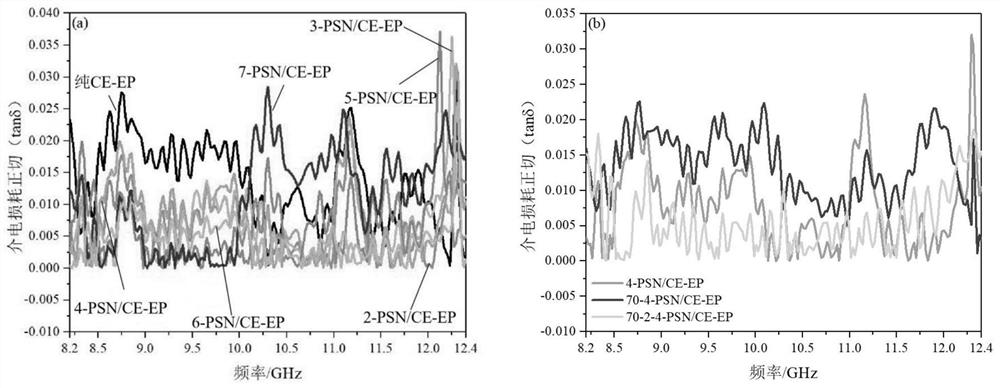

Embodiment 1

[0041] Heat 100g BADCy and 5g E-51 to 160°C, mix well, and react until the sample has no crystallization phenomenon, which is recorded as CE-EP prepolymer, wherein the mass of E-51 is 5% of the mass of BADCy;

[0042] Step 2. At 25°C, add the pretreated PSN to the prepolymer in step 1, wherein the added mass of the pretreated PSN is 2% of the prepolymer to obtain a modified cyanate, denoted as 2 -PSN / CE-EP.

[0043] The pretreated PSN was prepared according to the following method: put the original PSN into a round-bottomed flask, and use a rotary evaporator to perform rotary evaporation treatment. The conditions of the rotary evaporation treatment are: the rotation speed is 120r / min, and the temperature is 40°C. In order to remove the ammonia in the PSN, obtain the pretreated PSN.

[0044] Step 3. Add 0.01wt.% dibutyltin dilaurate to the modified cyanate, mix well to obtain a mixed solution, then add acetone to the mixed solution, the volume ratio of acetone to the mixed sol...

Embodiment 2

[0046] The method for preparing the modified cyanate is the same as in Example 1, except that in step 2, the added mass of pretreated PSN is 3% of the prepolymer. The prepared quartz fiber / modified cyanate composite material is denoted as QF / 3-PSN / CE-EP.

Embodiment 3

[0048] The method for preparing the modified cyanate is the same as that in Example 1, except that in step 2, the added mass of pretreated PSN is 4% of the prepolymer. The prepared quartz fiber / modified cyanate composite material is denoted as QF / 4-PSN / CE-EP.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com