Anti-reflection liquid for photovoltaic module glass as well as preparation method and application of anti-reflection liquid

A photovoltaic module and glass technology, applied in coatings and other directions, can solve the problems that the anti-reflection function cannot meet the long-term use requirements of photovoltaic cells, the use environment of photovoltaic cells is complex, and the surface is easy to adhere to dust and bird droppings, etc., and achieve excellent self-cleaning performance. , Improve self-cleaning performance, enhance film-forming compactness and adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

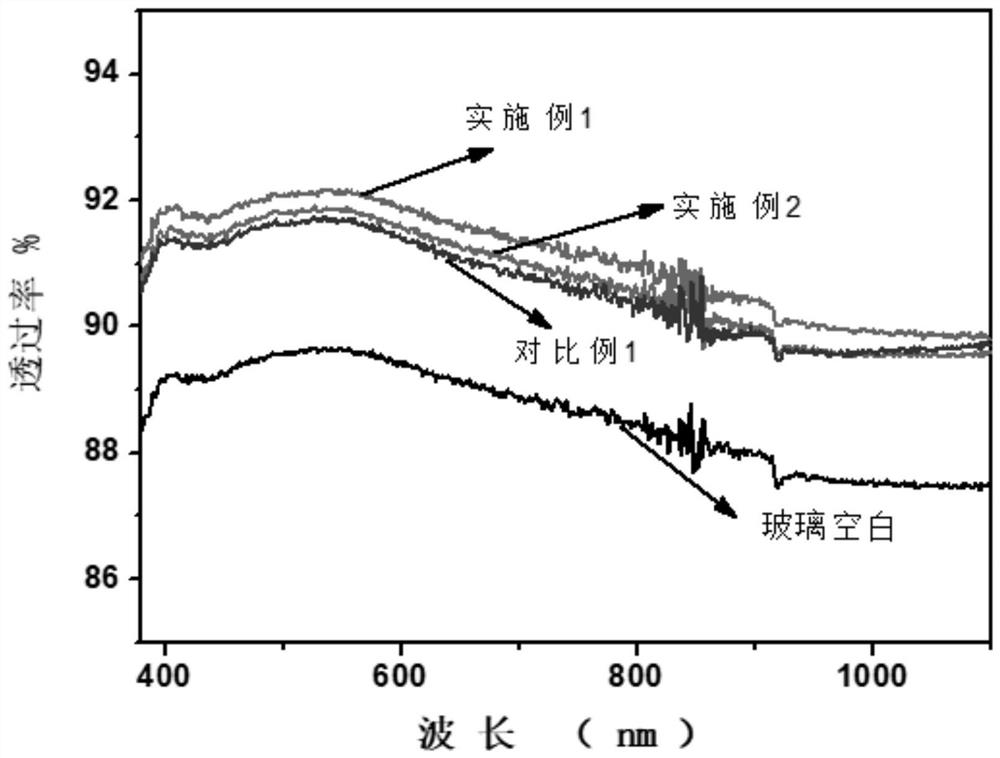

Embodiment 1

[0045] A method for preparing anti-reflection liquid for photovoltaic module glass in this embodiment comprises the following steps:

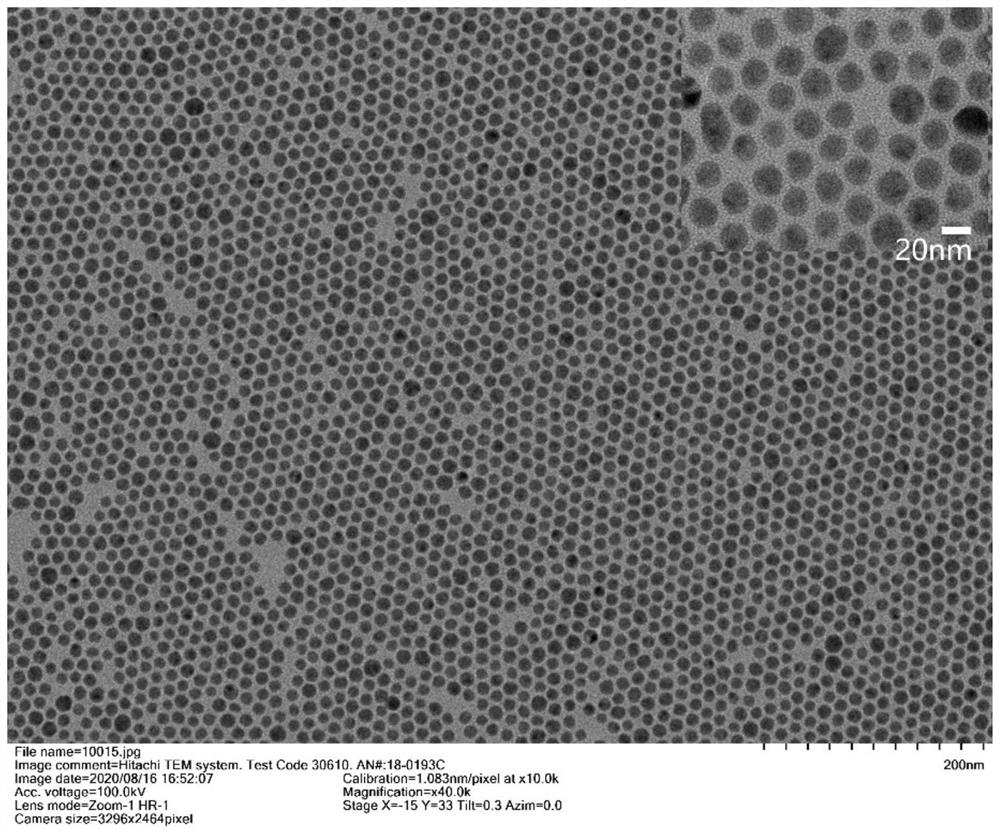

[0046] Step 1: Add 320g of absolute ethanol to the reactor, slowly drop 4.8mL of hydrochloric acid solution into the isopropanol, add 20mL of ultrapure water, stir well to obtain a solution with a pH of 1-2, and control the solution temperature to 30°C , use the dropping funnel to slowly add 90mL tetraethyl orthosilicate dropwise under stirring, the dropping speed is controlled at 10-20 drops per second. , so that the pH of the solution is 2-4 to obtain nano-scale acidic silica sol.

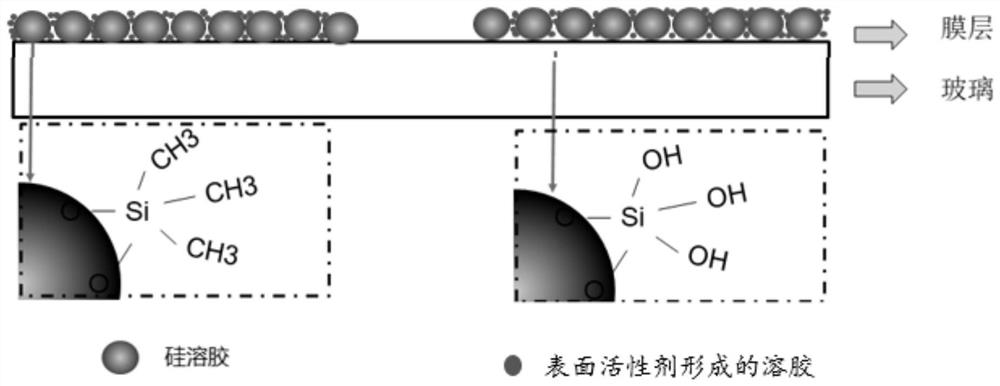

[0047] Step 2, then take 10mL of silica sol, add 15mL of water, 6mL of isopropanol, 17mL of absolute ethanol, 12mL of n-propanol, 30mL of methanol, 10mL of propylene glycol methyl ether and 0.5mL of ethyl polysilicate to adjust the pH to 9, then add a mixture of triethoxysilane and trimethoxysilane (mass ratio 1:1) accounting for 0.5% of the total solution as a h...

Embodiment 2

[0050] A method for preparing anti-reflection liquid for photovoltaic module glass in this embodiment comprises the following steps:

[0051] Step 1: Add 480g of n-propanol to the reactor, slowly drop 5.2mL of nitric acid solution into the isopropanol, add 25mL of ultrapure water, stir well to obtain a solution with a pH of 1-2, and control the solution temperature to 30°C , use the dropping funnel to slowly add 90mL tetraethyl orthosilicate dropwise under stirring, the dropping speed is controlled at 10-20 drops per second. , so that the pH of the solution is 2-4 to obtain nano-scale acidic silica sol.

[0052] Step 2, then take 8mL of silica sol, add 10mL of water, 6mL of isopropanol, 10mL of absolute ethanol, 12mL of n-propanol, 50mL of methanol, 10mL of propylene glycol methyl ether and 0.5mL of ethyl polysilicate to adjust the pH to 10, then add a mixed solution (mass ratio of 3:2) of methyl tri(trimethylsiloxane) silane and methyl triethoxysilane accounting for 0.3% of ...

Embodiment 3

[0055] A method for preparing anti-reflection liquid for photovoltaic module glass in this embodiment comprises the following steps:

[0056] Step 1: Add 320 g of methanol to the reactor, slowly add 4.8 mL of acetic acid solution dropwise into isopropanol, add 20 mL of ultrapure water, and stir evenly to obtain a solution with a pH of 1-2. Control the temperature of the solution to 35 ° C. Slowly add 90mL tetraethyl orthosilicate dropwise with stirring using a dropping funnel, the dropping speed is controlled at 10-20 drops per second, after the dropwise addition is completed, react at a constant temperature for 1.5h under stirring, and leave it open for 4 days. The pH of the solution is set at 2-4 to obtain nanoscale acidic silica sol.

[0057] Step 2, then take 10mL of silica sol, add 15mL of water, 6mL of isopropanol, 15mL of absolute ethanol, 8mL of n-propanol, 35mL of methanol, 12mL of propylene glycol methyl ether and 0.5mL of ethyl polysilicate to adjust the pH to 9, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com