Method for improving catalytic oxidation performance of silver-doped perovskite type metal oxide by etching silver-doped perovskite type metal oxide through reducing organic acid solution

A perovskite-type, catalytic oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem that the catalytic activity cannot meet the needs of industrial applications, etc. To achieve the effect of being conducive to large-scale production, stable structure, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

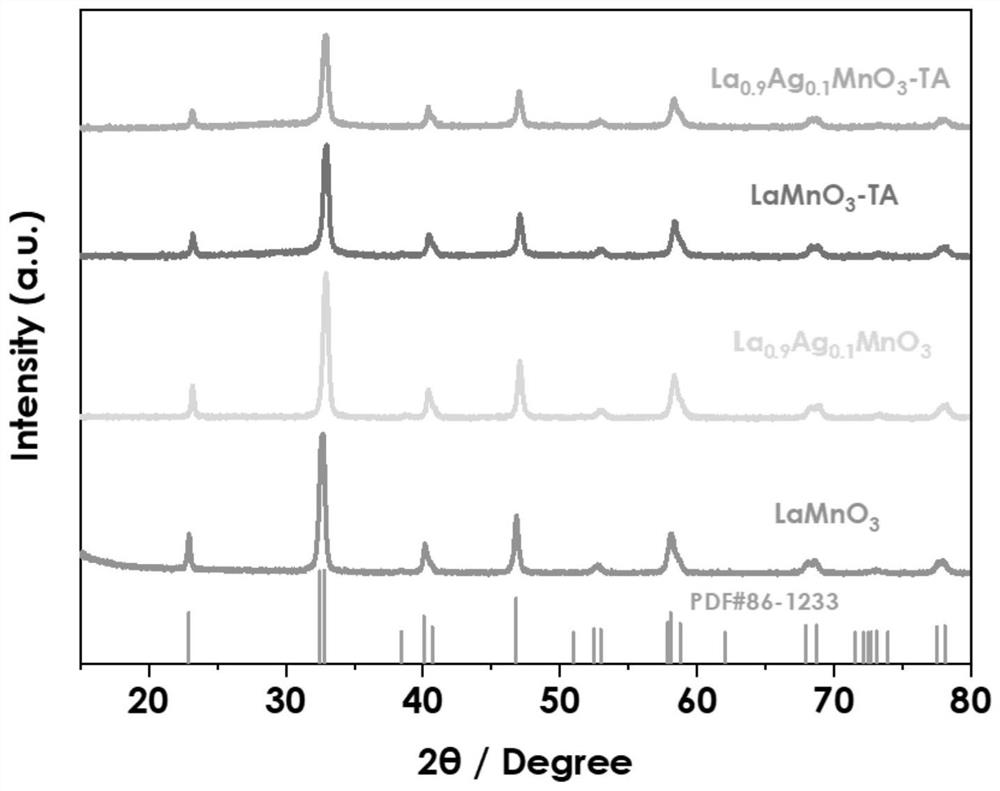

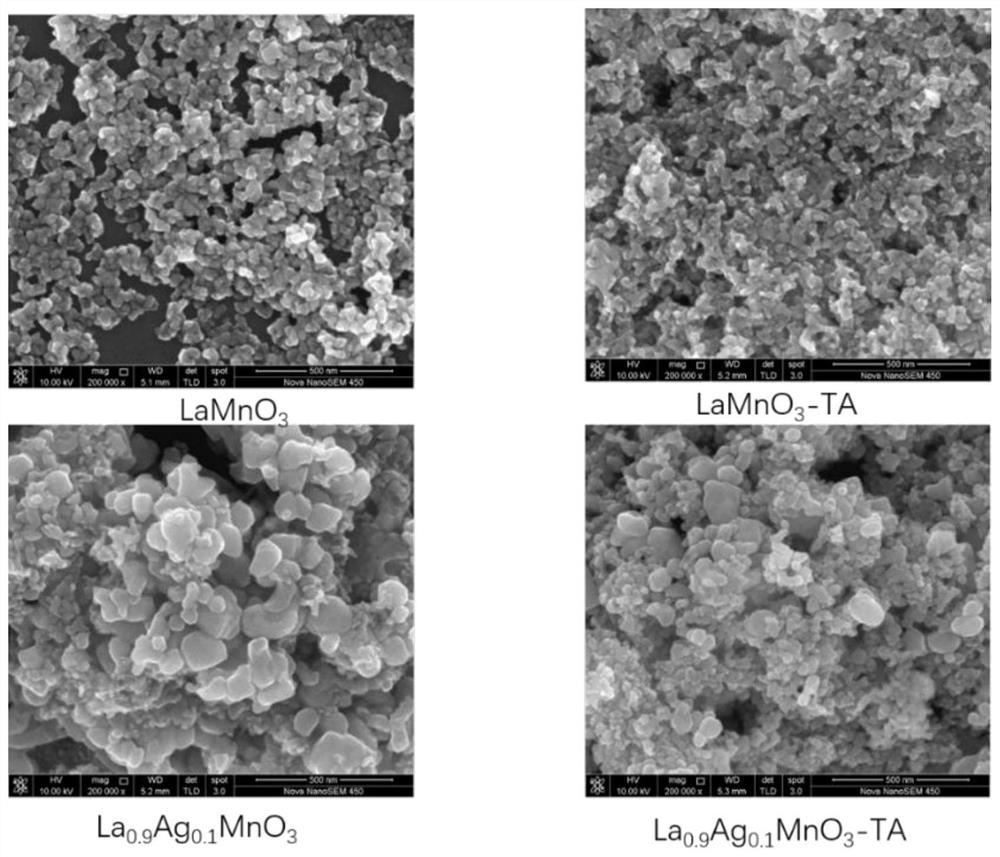

[0028] According to the literature (Ni-substituted LaMnO 3 perovskites for ethanol oxidation) in the citric acid sol-gel method to prepare LaMnO with perovskite structure 3 and silver-doped La 0.9 Ag 0.1 MnO 3 ;

[0029] Take 0.5g LaMnO 3 or La 0.9 Ag 0.1 MnO 3 Put the powder in a beaker, add 50 mL of L-tartaric acid solution with a concentration of 1 mol / L, stir magnetically at 25 °C for 1 h, then filter and wash, transfer the filter cake to an oven at 80 °C for 24 h.

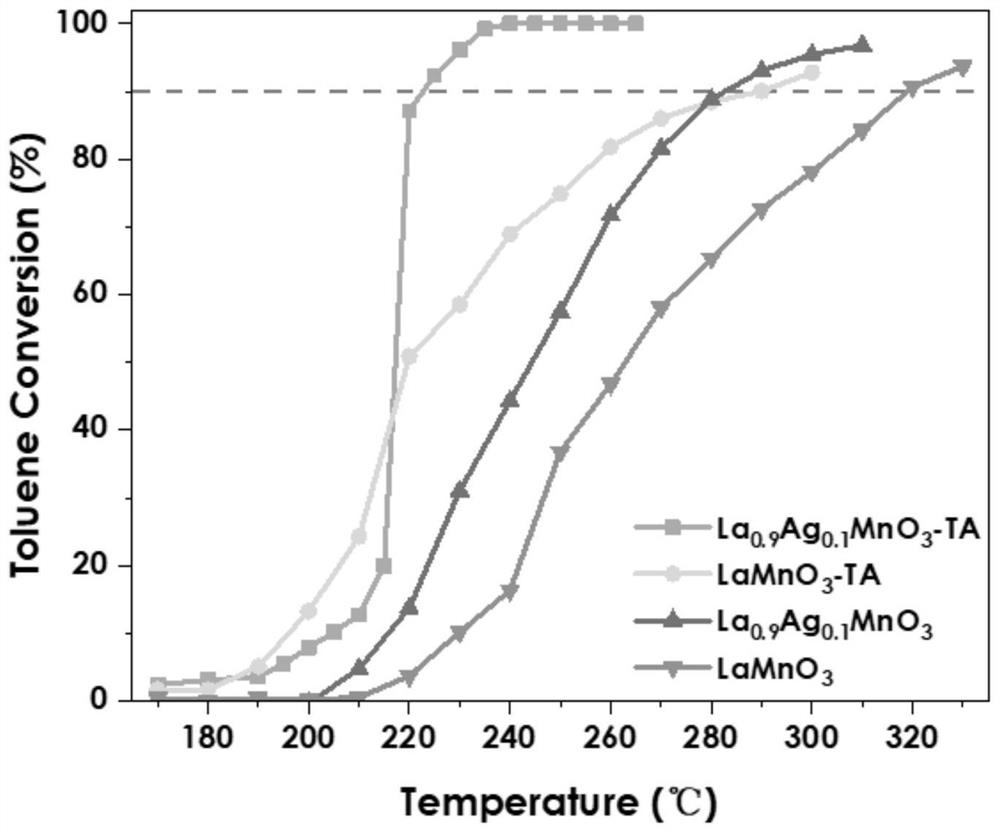

[0030] Press the powder into tablets and grind it into 40-60 mesh particles, and then evaluate the catalytic combustion performance of toluene. The evaluation conditions are: put 100mg of catalyst into the reactor, feed 100ml / min of synthetic air with a toluene concentration of 1000ppm , 20vol%O 2 , 80vol%N 2 . WHSV=60000mL·g -1 h -1 . The toluene catalytic combustion effect of the catalyst is shown in Table 1.

Embodiment 2

[0032] According to the literature (Improvements in electrical and dielectric properties of substituted multiferroic LaMnO 3 based nanostructures synthesized by co-precipitation method) in the co-precipitation method, the preparation of silver ion-doped La with perovskite structure 0.8 Ag 0.2 MnO3 ;

[0033] Take 0.5g La 0.9 Ag 0.2 MnO 3 Put the powder in a beaker, add 50mL of 2mol / L D-tartaric acid solution, magnetically stir at 40°C for 2h, then filter and wash, transfer the filter cake to an oven for 24h at 80°C.

[0034] Press the powder into tablets and grind it into 40-60 mesh particles, and then evaluate the catalytic combustion performance of toluene. The evaluation conditions are: put 100mg of catalyst into the reactor, feed 100ml / min of synthetic air with a toluene concentration of 1000ppm , 20vol%O 2 , 80vol%N 2 . WHSV=60000mL·g -1 h -1 . The toluene catalytic combustion effect of the catalyst is shown in Table 1.

Embodiment 3

[0036] According to the hydrothermal synthesis method in the literature (Engineering highly active oxygen sites in perovskite oxides for stable and efficient oxygen evolution), silver ion-doped La 0.9 Ag 0.1 CoO 3 ;

[0037] Take 0.5g La 0.9 Ag 0.1 CoO 3 Put the powder in a beaker, add 50mL of a mixed solution of D-tartaric acid and L-tartaric acid with a concentration of 1mol / L, stir magnetically at 25°C for 2h, then filter and wash, transfer the filter cake to an oven at 80°C for 24h.

[0038] Press the powder into tablets and grind it into 40-60 mesh particles, and then evaluate the catalytic combustion performance of toluene. The evaluation conditions are: put 100 mg of catalyst into the reactor, feed 100 mL / min of synthetic air with a toluene concentration of 1000 ppm , 20vol%O 2 , 80vol% N 2 . WHSV=60000mL·g -1 h -1 . The toluene catalytic combustion effect of the catalyst is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com