Graphene oxide-based porous photo-thermal material capable of efficiently generating solar steam, preparation method and application thereof

A technology of solar steam and graphene, which is applied in the steam generation method using solar energy, solar thermal energy, solar thermal power generation, etc., can solve the problem of reducing the photothermal conversion efficiency of photothermal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

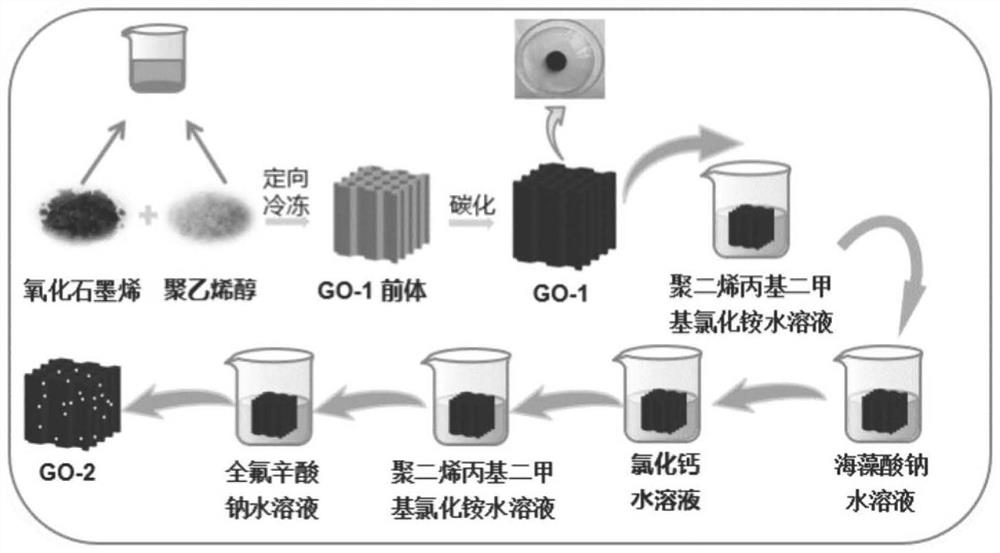

[0030] The steps of the preparation method of the graphene oxide-based porous photothermal material capable of efficiently generating solar steam of the present invention are as follows:

[0031] 1. Preparation of graphene oxide by hummers method

[0032] (1) Graphite pre-oxidation

[0033] Take 7.5mL of concentrated sulfuric acid, 1.5g of potassium peroxodisulfate and 1.5g of phosphorus pentoxide in a 50mL three-necked flask, heat to 90°C, stir for 15min and then cool to 80°C. 1.8 g of graphite powder was slowly added thereto, the temperature was kept at 80° C., and the mixture was stirred for 4.5 h to form a black precipitated mixture. After the reaction, the mixture was cooled to room temperature, diluted with 300 mL of deionized water, allowed to stand overnight, washed with distilled water to neutralize the treated graphite, and dried at room temperature for 24 hours to obtain pre-oxidized graphite.

[0034] Among them, concentrated sulfuric acid and phosphorus pentoxid...

Embodiment 1

[0047] Example 1 Preparation of aligned graphene oxide-based porous photothermal materials

[0048] 1. Preparation of graphene oxide by hummers method

[0049] (1) Graphite pre-oxidation

[0050] Take 7.5mL of concentrated sulfuric acid, 1.5g of potassium peroxodisulfate and 1.5g of phosphorus pentoxide in a 50mL three-necked flask, heat to 90°C, stir for 15min and then cool to 80°C. 1.8 g of graphite powder was slowly added thereto, the temperature was kept at 80° C., and the mixture was stirred for 4.5 h to form a black precipitated mixture. After the reaction, the mixture was cooled to room temperature, diluted with 300 mL of deionized water, allowed to stand overnight, washed with distilled water until neutral, and dried at room temperature for 24 hours to obtain pre-oxidized graphite.

[0051] (2) Preparation of graphene oxide

[0052] Measure 19 mL of concentrated sulfuric acid into a 250 mL three-necked flask, and cool it to about 0°C with an ice-water bath. Add the...

Embodiment 2

[0062] Example 2 Preparation of hydrophilic and oleophobic graphene oxide-based porous photothermal material

[0063] (1) Preparation of aligned graphene oxide-based porous photothermal material (GO-1): the same as in Example 1.

[0064](2) Immerse GO-1 in polydiallyldimethylammonium chloride (PDDA, 1.0 mg / L) solution for 20 min to make the surface positively charged, and then immerse PDDA-modified GO-1 in alginic acid Ca was obtained after soaking in sodium salt solution (0.4wt%) for 2min and then in calcium chloride solution (0.1M) for 20min 2+ / Alginate hydrogel coating. Finally, the Ca 2+ / The surface covered by alginate hydrogel was immersed in PDDA solution (1.0 mg / L) for 2 min, then immersed in sodium perfluorooctanoate (PFO, 0.1 M) solution for 20 min, and dried at room temperature to obtain hydrophilic and oleophobic graphene oxide-based porous light Thermal material, named GO-2.

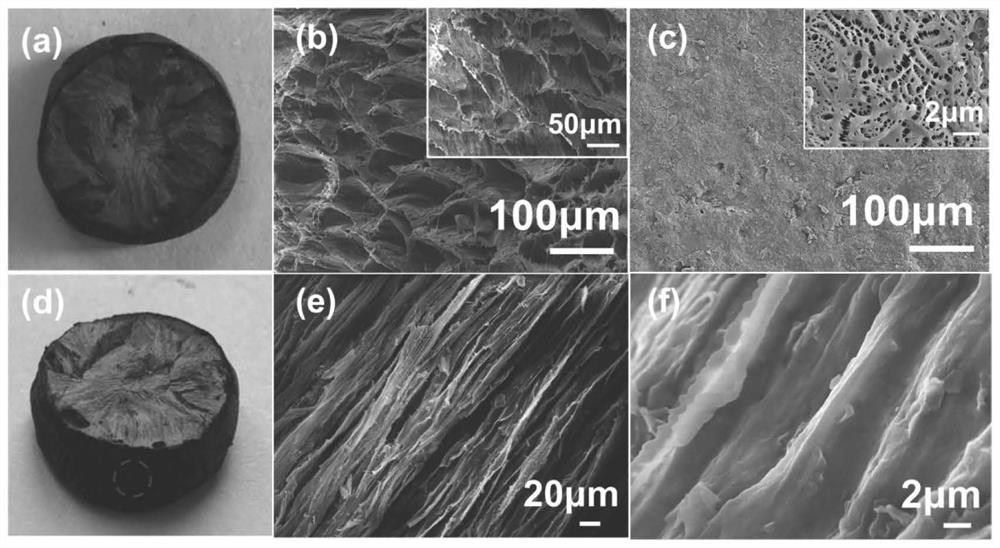

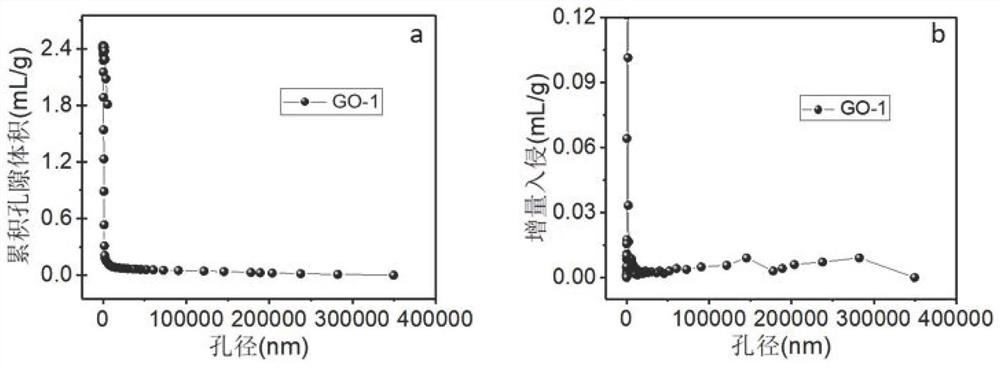

[0065] like figure 2 Shown in c is the scanning electron microscope image of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com