A kind of cordierite-based sagger and its production process

A production process, cordierite technology, applied in the field of cordierite-based sagger and its production process, can solve the problems of high porosity, easy to be corroded, affecting the purity of positive electrode materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

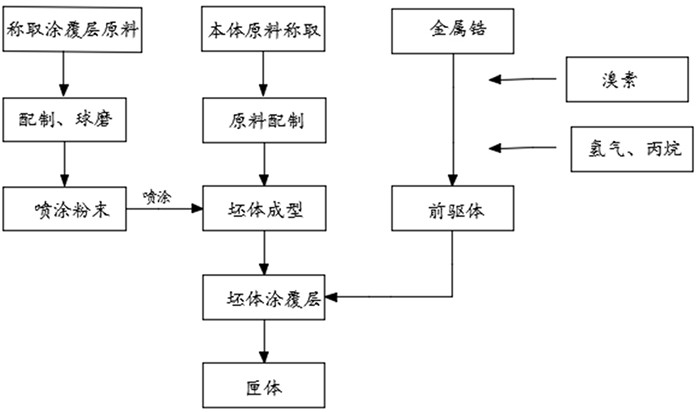

Image

Examples

Embodiment 1

[0031] Described filler comprises the following steps to make:

[0032] Step S1, adding graphene oxide into deionized water, adding dropwise 15% aqueous sodium hydroxide solution to adjust the pH until pH=10, then adding boric acid, stirring at a constant speed for 5 minutes, adding ethylenediamine, and continuing to stir for 5 minutes to obtain a mixed Liquid, transferred to the reaction kettle, heated to 100 ° C, kept warm and reacted for 6 hours, after the reaction was placed in 15% ethanol aqueous solution with a volume fraction of dialysis for 12 hours, to remove residues such as ethylenediamine, to obtain hydrogel, control graphene oxide , the weight ratio of boric acid, ethylenediamine and deionized water is 5: 0.3: 0.8: 50;

[0033] Step S2: Add zirconium acetate to absolute ethanol, heat in a water bath at 45°C, slowly add acetylacetone dropwise, keep warm for 1 hour, then slowly add triethylamine dropwise, keep warm and react for 4 hours, then cool down to room tempe...

Embodiment 2

[0036] Described filler comprises the following steps to make:

[0037]Step S1, adding graphene oxide into deionized water, adding dropwise 15% aqueous sodium hydroxide solution to adjust the pH until pH = 11, then adding boric acid, stirring at a constant speed for 5 minutes, adding ethylenediamine, and continuing to stir for 5 minutes to obtain a mixed Liquid, transferred to the reaction kettle, heated to 110 ° C, kept warm and reacted for 6 hours, after the reaction was dialyzed in 15% ethanol aqueous solution for 12 hours to remove residues such as ethylenediamine, and obtained a hydrogel to control graphene oxide , the weight ratio of boric acid, ethylenediamine and deionized water is 8: 0.4: 1.0: 50;

[0038] Step S2: Add zirconium acetate to absolute ethanol, heat in a water bath at 50°C, slowly add acetylacetone dropwise, keep warm for 1 hour, then slowly add triethylamine dropwise, keep warm and react for 4 hours, then cool down to room temperature, add dropwise aceti...

Embodiment 3

[0041] Described filler comprises the following steps to make:

[0042] Step S1, adding graphene oxide into deionized water, adding dropwise 15% aqueous sodium hydroxide solution to adjust the pH until pH=12, then adding boric acid, stirring at a constant speed for 5 minutes, adding ethylenediamine, and continuing to stir for 5 minutes to obtain a mixed Liquid, transferred to the reaction kettle, heated to 120 ° C, kept warm and reacted for 6 hours, after the reaction was placed in 15% ethanol aqueous solution for dialysis for 12 hours, to remove residues such as ethylenediamine, to obtain hydrogel, control graphene oxide , the weight ratio of boric acid, ethylenediamine and deionized water is 10: 0.5: 1.2: 50;

[0043] Step S2: Add zirconium acetate to absolute ethanol, heat in a water bath at 65°C, slowly add acetylacetone dropwise, keep warm for 1 hour, then slowly add triethylamine dropwise, keep warm and react for 4 hours, then cool down to room temperature, add dropwise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com