Poly (amide-thioamide) polymer, synthesis method and application thereof

A technology of thioamide and synthesis method, which is applied in the field of polymer chemical materials and achieves the effect of high molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

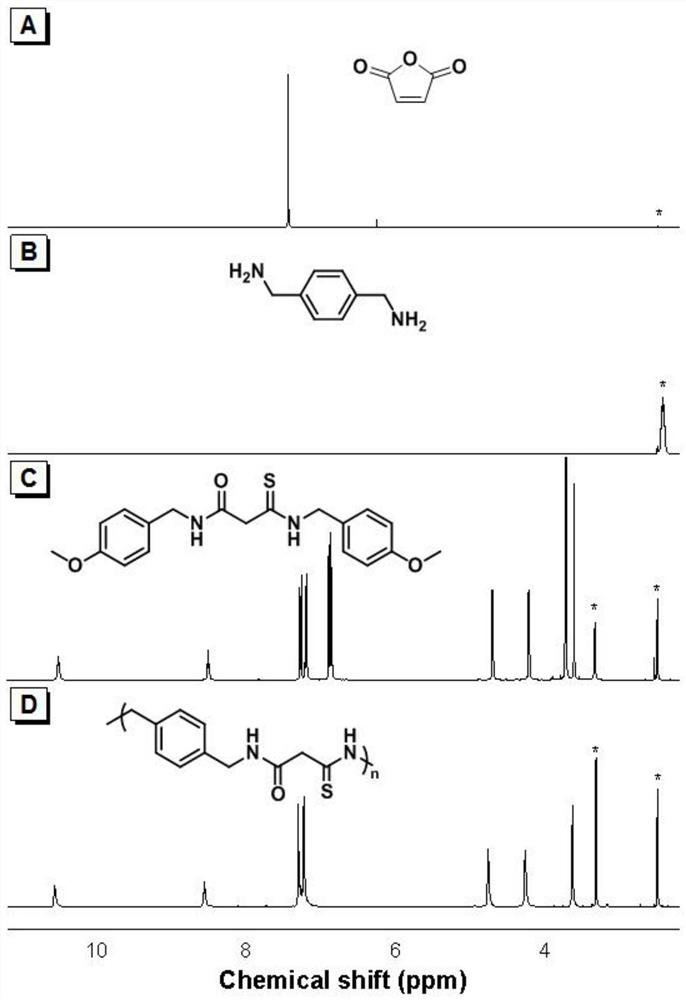

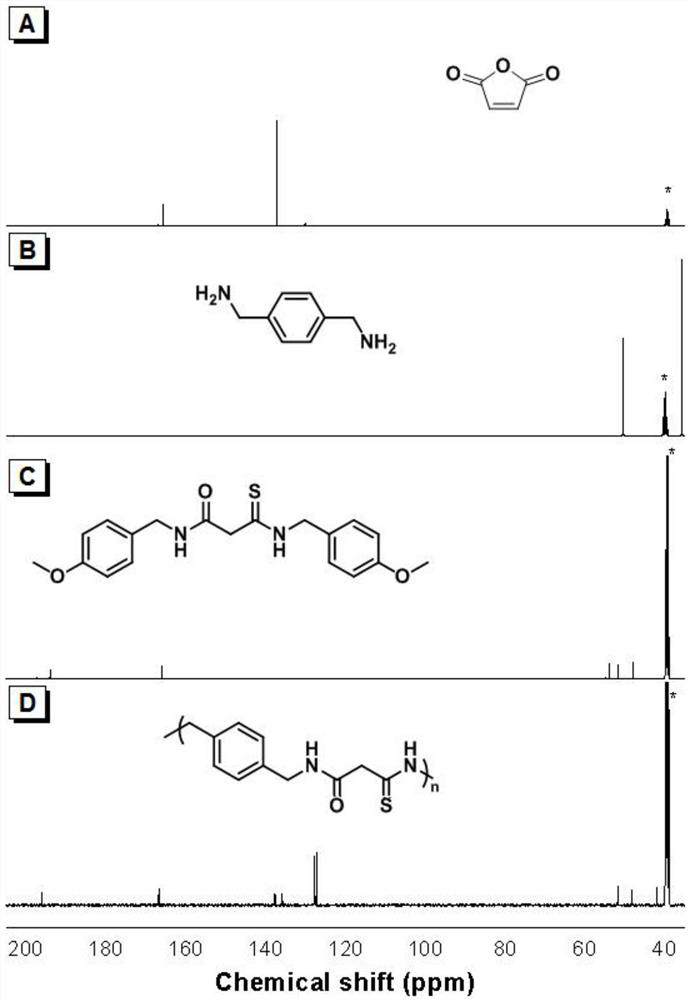

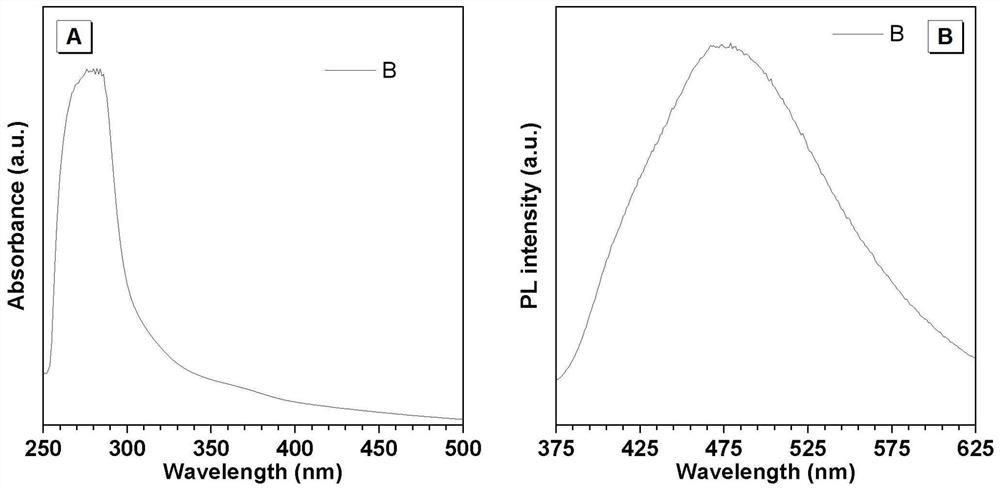

[0053] The invention provides a kind of synthetic method of poly(amide-thioamide) polymer, comprises the following steps:

[0054] Under an inert gas environment, add difunctional amine monomer, maleic anhydride and elemental sulfur into an organic solvent to react to obtain a reaction liquid, dilute the reaction liquid, filter, and settle to obtain poly(amide-thioamide) polymer.

[0055] In the present invention, the molar ratio of the difunctional amine monomer, maleic anhydride and elemental sulfur is 1:0.5-1.95:1.5-6, preferably 1:0.8-1.8:2.0-5, more preferably 1:1.0:3.5.

[0056] In the present invention, the difunctional amine monomer comprises the following compounds:

[0057]

[0058] Wherein, n and k are integers of 1-20.

[0059] The difunctional amine monomer is preferably:

[0060]

[0061] The difunctional amine monomer is further preferably:

[0062]

[0063] In the present invention, the inert gas is preferably nitrogen and / or argon, more preferabl...

Embodiment 1

[0094] The reaction equation for polymer P1 is as follows:

[0095]

[0096] where P1 contains structure.

[0097] The synthetic steps of this polymer are as follows:

[0098] In a reactor filled with nitrogen, mix dimethyl sulfoxide, N,N-dimethylformamide and N-methylpiperidine in a mass ratio of 1:3:0.1, and then add them to a molar ratio of 1: 1:2.5 in p-xylylenediamine, maleic anhydride, and sublimed sulfur, dissolve it, and stir at room temperature for 15 minutes, then raise the temperature to 90° C., and stir for 16 hours.

[0099]After the reaction was completed, dimethyl sulfoxide was added thereto to dilute the reaction solution, and the temperature was cooled to room temperature. Thereafter, the reaction solution was passed through a glass dropper filled with cotton at a rate of 2 drops per second, and the residual sulfur was filtered, and then 100 mL of methanol as a precipitant was added to the filtrate. The polymer precipitated in methanol was filtered, ...

Embodiment 2

[0108] The reaction equation of polymer P2 is as follows:

[0109]

[0110] Among them, P2 contains structure.

[0111] The synthetic steps of this polymer are as follows:

[0112] In a reactor filled with argon gas, mix dimethyl sulfoxide, N,N-dimethylformamide and N-methylpiperidine in a mass ratio of 1:3:0.1, and then add them to a molar ratio of 1 : 1:2.5 in 4,4'-diaminodiphenylmethane, maleic anhydride and sublimed sulfur, dissolve it, stir at room temperature for 15 minutes, then raise the temperature to 90°C and stir for 6 hours;

[0113] After the reaction was completed, dimethyl sulfoxide was quickly added therein to dilute the reaction solution, and the temperature was lowered to room temperature. Thereafter, the reaction solution was passed through a glass dropper filled with cotton at a rate of 1 drop per second to filter the residual sulfur, and then 100 mL of methanol as a precipitant was added to the filtrate. The polymer precipitated in methanol was f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com