Graphdiyne synthesis method

A synthesis method and technology of graphyne, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of high reaction temperature, long reaction cycle, difficulty in realizing graphyne macro-preparation, etc., and achieve the effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

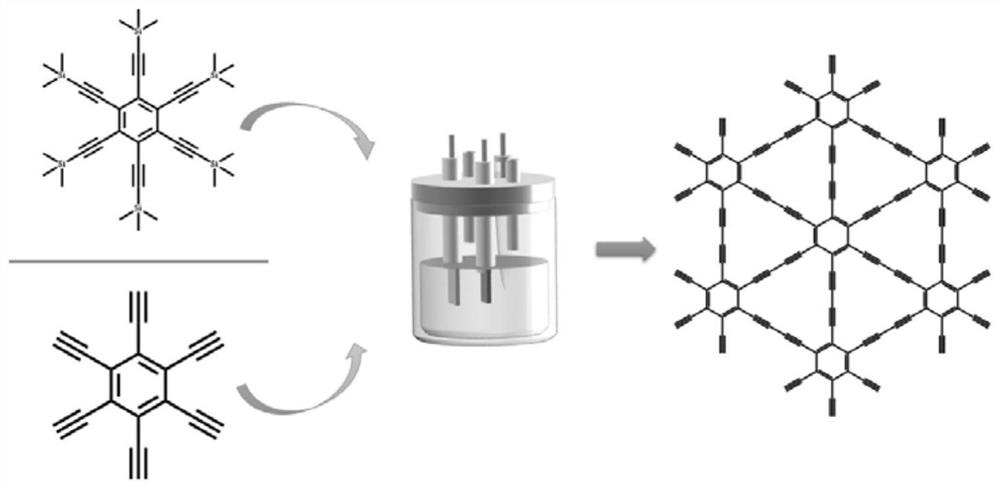

Method used

Image

Examples

Embodiment 1

[0074] In this example, using hexa[tris(methylsilyl)ethynyl]benzene as a precursor, graphyne was synthesized by cyclic voltammetry. Specifically:

[0075] Dissolve 8 mg of hexa[tris(methylsilyl)ethynyl]benzene in 15 mL of tetrahydrofuran, and then add the monomer solution to 15 mL of 0.1 mol / L zinc salt / dimethyl sulfoxide solution to prepare the electrolyte . Keep the temperature of the system at 50°C, use copper foil and platinum sheet as the working electrode and the counter electrode respectively, set the potential window to 0 to 1V, set the sweep rate to 5mV / s, and set the number of cycles to 10 to obtain graphyne. After the reaction, the working electrode was rinsed with acetone and hot N,N-dimethylformamide in sequence, and dried with nitrogen.

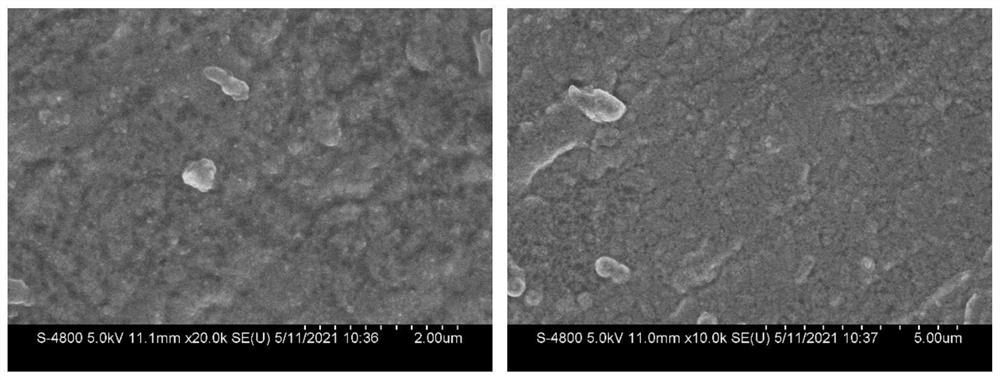

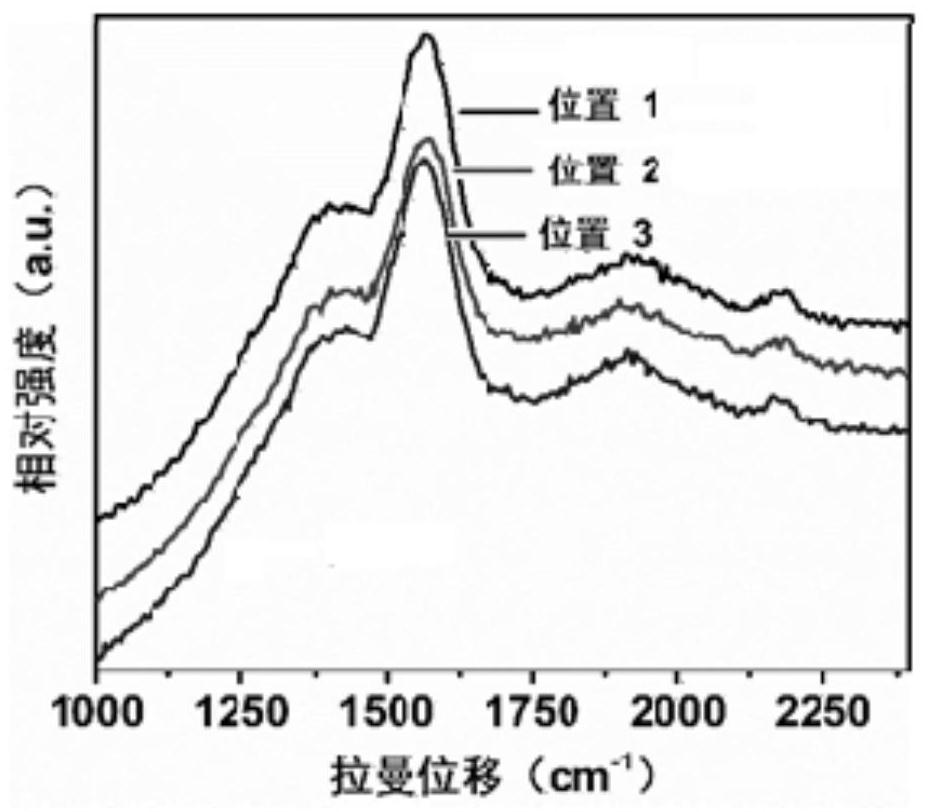

[0076] Figure 2-4 They are the SEM image, Raman spectrum image and XPS image of graphyne synthesized by cyclic voltammetry. Raman spectroscopy is an important means to confirm the structure of graphyne. from image 3 It ...

Embodiment 2

[0078] In this example, hexa[tris(methylsilyl)ethynyl]benzene was used as a precursor to synthesize graphyne by a potentiostatic method. Specifically:

[0079] Dissolve 8 mg of hexa[tris(methylsilyl)ethynyl]benzene into 15 mL of tetrahydrofuran, and then add the monomer solution into 15 mL of 1 mol / L zinc salt / dimethyl sulfoxide solution to prepare an electrolyte. At 50°C and a voltage of 0.6V, copper foil and platinum sheet were used as the working electrode and the counter electrode respectively, and the graphyne was prepared by reacting for 1600s. After the reaction, the working electrode was rinsed with acetone and hot N,N-dimethylformamide in sequence, and dried with nitrogen.

[0080] Figure 5 , 6 SEM images and Raman spectra of graphyne synthesized by potentiostatic method, respectively. from Image 6 It can be seen that 1372.5cm -1 、1536.9cm -1 、1913.2cm -1 、2171.5cm -1 There is a Raman absorption peak at 1372.5cm -1 The absorption peak at can be attributed ...

Embodiment 3

[0082] In this example, a graphyne material was synthesized by cyclic voltammetry using hexaethynylbenzene as a precursor. specific method:

[0083]Dissolve 32.95 mg of hexa[tris(methylsilyl)ethynyl]benzene in tetrahydrofuran, deprotect with 1M tetrabutylammonium fluoride (TBAF) in tetrahydrofuran under an argon atmosphere, and deprotect with ethyl acetate after 15 minutes Dilute and extract with saturated saline, spin dry and use immediately. Dissolve the hexaethynylbenzene solid obtained by deprotection into 50mL dimethyl sulfoxide, and add it dropwise to 50mL 1mol / L zinc salt / dimethyl sulfoxide solution within 2h under an argon atmosphere, protected from light , the solution is the electrolyte. During the above dropping process, the temperature of the system was kept at 50°C, copper foil, platinum sheet and Ag / AgCl electrode were used as working electrode, counter electrode and reference electrode respectively, the potential window was set to 0 to 0.6V, and the scan rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com