TPEE monofilament

A monofilament and masterbatch technology, which is applied in the field of TPEE monofilament, can solve the problems of inability to achieve anti-ultraviolet effect, uneven dispersion of ultraviolet absorbers, and unfavorable anti-ultraviolet effect, and achieve long-term and excellent anti-ultraviolet effect, improve Anti-ultraviolet effect, effect of solving dispersion problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

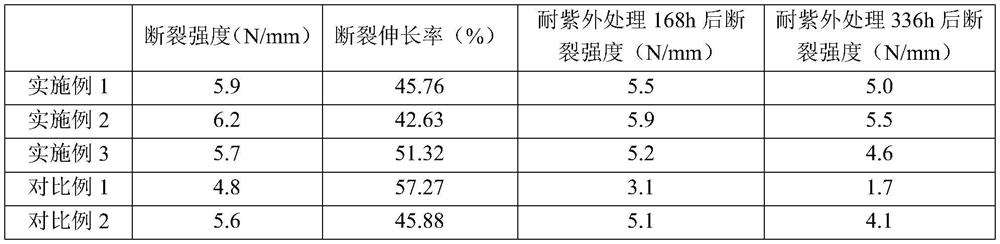

Embodiment 1

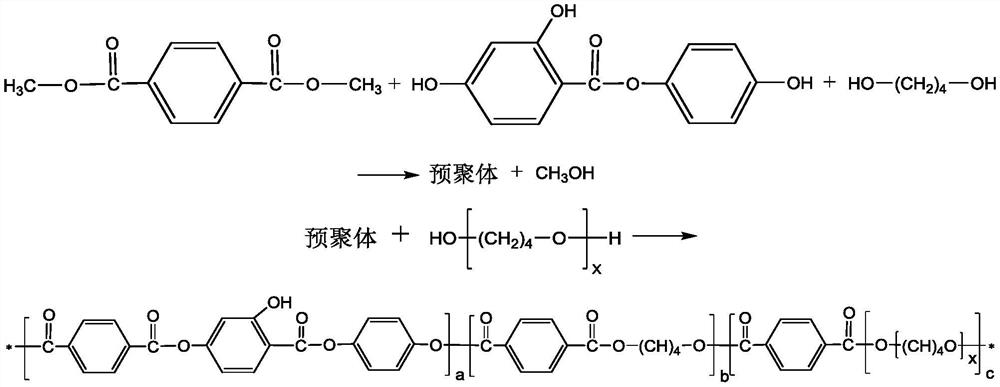

[0030] Preparation of UV-resistant modified TPEE masterbatch:

[0031] (1) Add 2kg of 1,4-butanediol, 0.58kg of 2,4-dihydroxybenzoic acid-4-hydroxyphenyl ester and 2.27kg of dimethyl terephthalate into the reactor, and add the catalyst Magnesium acetate, feed nitrogen to exhaust the air, heat up to 185 ° C, and carry out transesterification. When the amount of methanol collected reaches 80% of the theoretical value, the transesterification is over and the prepolymer is obtained;

[0032] (2) Raise the temperature of the prepolymer to 230°C, add 5.2kg of polytetrahydrofuran ether diol and catalyst tetrabutyl titanate, turn off the nitrogen, evacuate until the pressure in the kettle drops below 100Pa, and slowly raise the temperature to 260°C for polycondensation After reacting for 2 hours, an anti-ultraviolet modified TPEE masterbatch was obtained.

[0033] Preparation of TPEE monofilament:

[0034] (1) Dry the prepared anti-ultraviolet modified TPEE masterbatch at 100°C for ...

Embodiment 2

[0037] Preparation of UV-resistant modified TPEE masterbatch:

[0038] (1) Add 2kg of 1,4-butanediol, 0.91kg of 2,4-dihydroxybenzoic acid-4-hydroxyphenyl ester and 2.39kg of dimethyl terephthalate into the reactor, and add the catalyst Magnesium acetate, feed nitrogen to exhaust the air, heat up to 185 ° C, and carry out transesterification. When the amount of methanol collected reaches 80% of the theoretical value, the transesterification is over and the prepolymer is obtained;

[0039] (2) Raise the temperature of the prepolymer to 230°C, add 5.5kg of polytetrahydrofuran ether glycol and catalyst tetrabutyl titanate, turn off the nitrogen, evacuate until the pressure in the kettle drops below 100Pa, and slowly raise the temperature to 260°C for polycondensation After reacting for 3 hours, an anti-ultraviolet modified TPEE masterbatch was obtained.

[0040] Preparation of TPEE monofilament:

[0041] (1) Dry the prepared anti-ultraviolet modified TPEE masterbatch at 100°C fo...

Embodiment 3

[0044] Preparation of UV-resistant modified TPEE masterbatch:

[0045] (1) Add 2kg of 1,4-butanediol, 0.27kg of 2,4-dihydroxybenzoic acid-4-hydroxyphenyl ester and 2.15kg of dimethyl terephthalate into the reactor, and add the catalyst Magnesium acetate, feed nitrogen to exhaust the air, heat up to 185 ° C, and carry out transesterification. When the amount of methanol collected reaches 80% of the theoretical value, the transesterification is over and the prepolymer is obtained;

[0046] (2) Raise the temperature of the prepolymer to 230°C, add 4.9kg of polytetrahydrofuran ether diol and catalyst tetrabutyl titanate, turn off the nitrogen, evacuate until the pressure in the kettle drops below 100Pa, and slowly raise the temperature to 260°C for polycondensation After reacting for 2 hours, an anti-ultraviolet modified TPEE masterbatch was obtained.

[0047] Preparation of TPEE monofilament:

[0048] (1) Dry the prepared anti-ultraviolet modified TPEE masterbatch at 100°C for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com