Water-blocking yarn, preparation method of water-blocking yarn and application of water-blocking yarn in optical cable and fiber sleeve

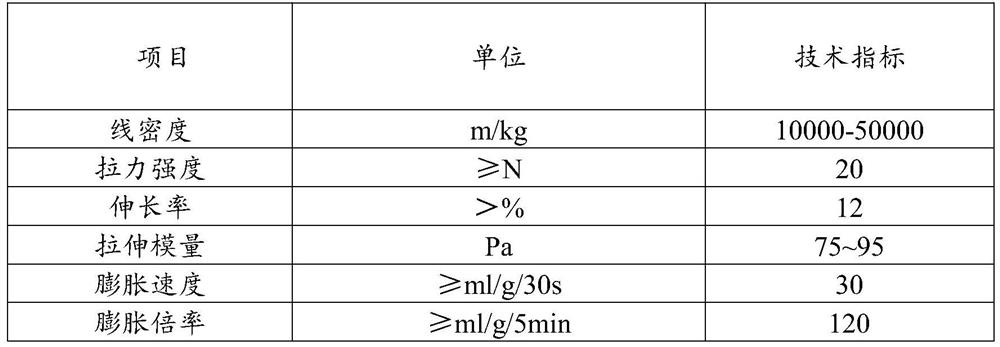

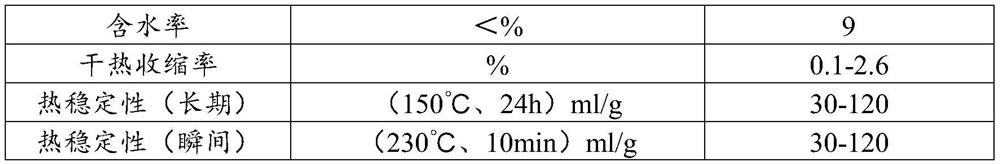

A yarn and water-blocking technology, which is applied in the field of water-blocking yarn and its preparation, can solve problems such as slow water absorption rate, high attenuation rate of optical fiber and cable transmission signals, and unsatisfactory water-blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the water-blocking yarn described in the above scheme, comprising the following steps:

[0036] mixing water, acrylic acid, sodium hydroxide, magnesium salt, calcium salt, foaming agent, dispersant, cross-linking agent and initiator to obtain a synthetic liquid for the water-absorbing swelling layer;

[0037] The polyester filaments are first immersed in the water-absorbing swellable layer synthesis liquid and then heated and polymerized to form a water-absorbing swellable layer on the surface of the polyester long fibers to obtain polyester long fibers coated with a water-absorbent swellable layer;

[0038] The acrylic water-based latex is mixed with water to obtain a water-based glue, and the polyester filament coated with a water-absorbing swelling layer is immersed in the water-based glue for a second time and then dried to obtain the water-blocking yarn.

[0039] In the present invention, water, acrylic aci...

Embodiment 1

[0048] Take 200 parts of deionized water, 100 parts of acrylic acid, 75 parts of sodium hydroxide, 30 parts of magnesium chloride, 21 parts of calcium chloride, 3 parts of sodium bicarbonate, 10 parts of fumed silica, crosslinking agent (polyethylene glycol diacrylic acid ester) 4 parts, initiator (sodium persulfate) 5 parts, the above components are mixed to obtain a water-absorbing swelling layer synthetic liquid;

[0049] The polyester long fibers are immersed in the water-absorbing swelling layer synthetic solution for 2 seconds, the mass ratio of the polyester long fibers and the water-absorbing swelling layer synthetic liquid hanging on the polyester long fibers is 10:2, and then placed in a methanol hot blast stove Heating to polymerize the synthetic solution on the polyester filaments, the temperature of the heating polymerization is 220°C, and the time is 1min, to obtain polyester filaments coated with a water-absorbing swelling layer;

[0050] Mix acrylic water-based...

Embodiment 2

[0052] Other conditions are the same as in Example 1, except that the composition of the water-absorbing swelling layer synthesis liquid is changed to: 150 parts of deionized water, 70 parts of acrylic acid, 60 parts of sodium hydroxide, 5 parts of magnesium acetate, 10 parts of calcium acetate, and 5 parts of sodium bicarbonate Parts, 5 parts of fumed silica, 2 parts of crosslinking agent (N,N-methylene acrylamide), 2 parts of initiator (potassium persulfate).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com