Low-pressure in-situ antibacterial repair-promoting electrospinning dressing and preparation method thereof

An electrospinning, in-situ technology, used in electrospinning, textiles and papermaking, medical science, etc., can solve safety problems, secondary wound injuries, etc., achieve strong water absorption, promote collagen proliferation, and spin speed. Toxic and pollution-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

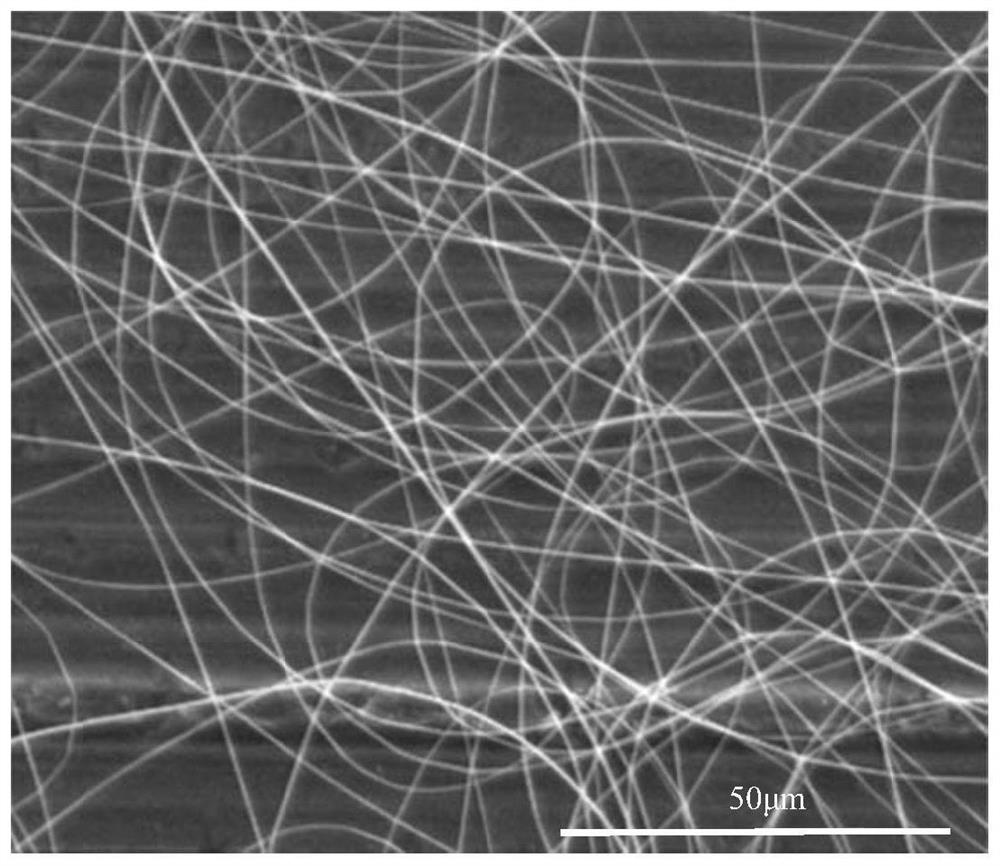

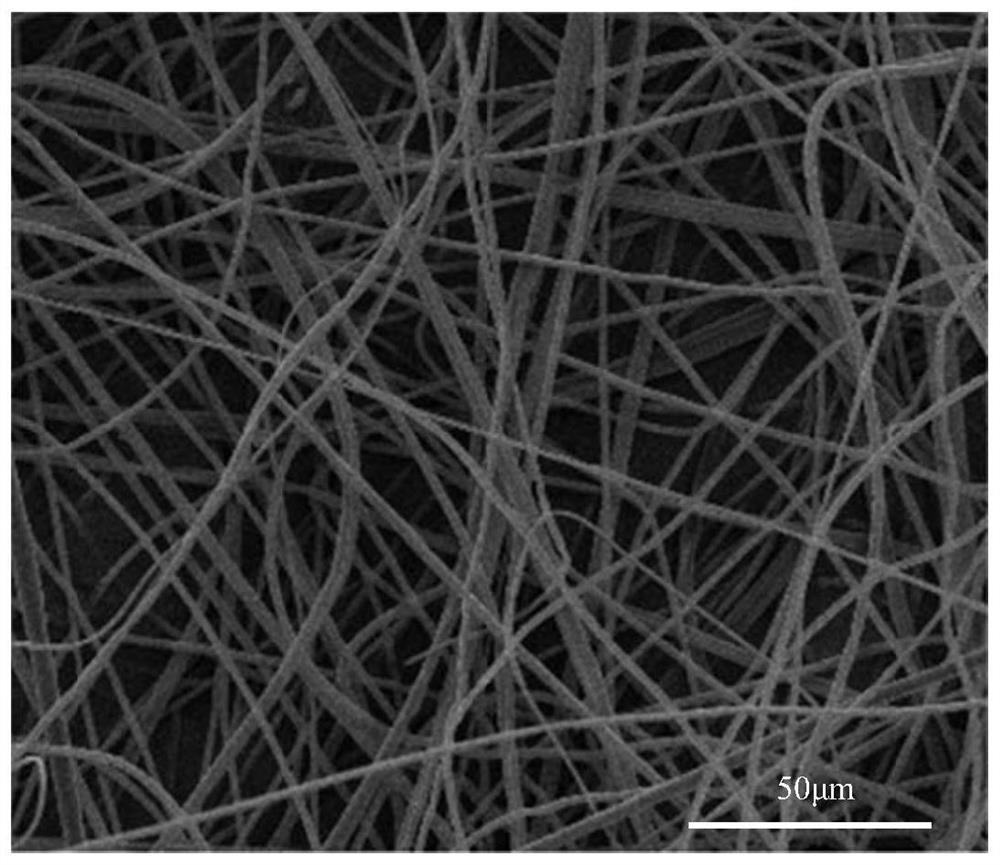

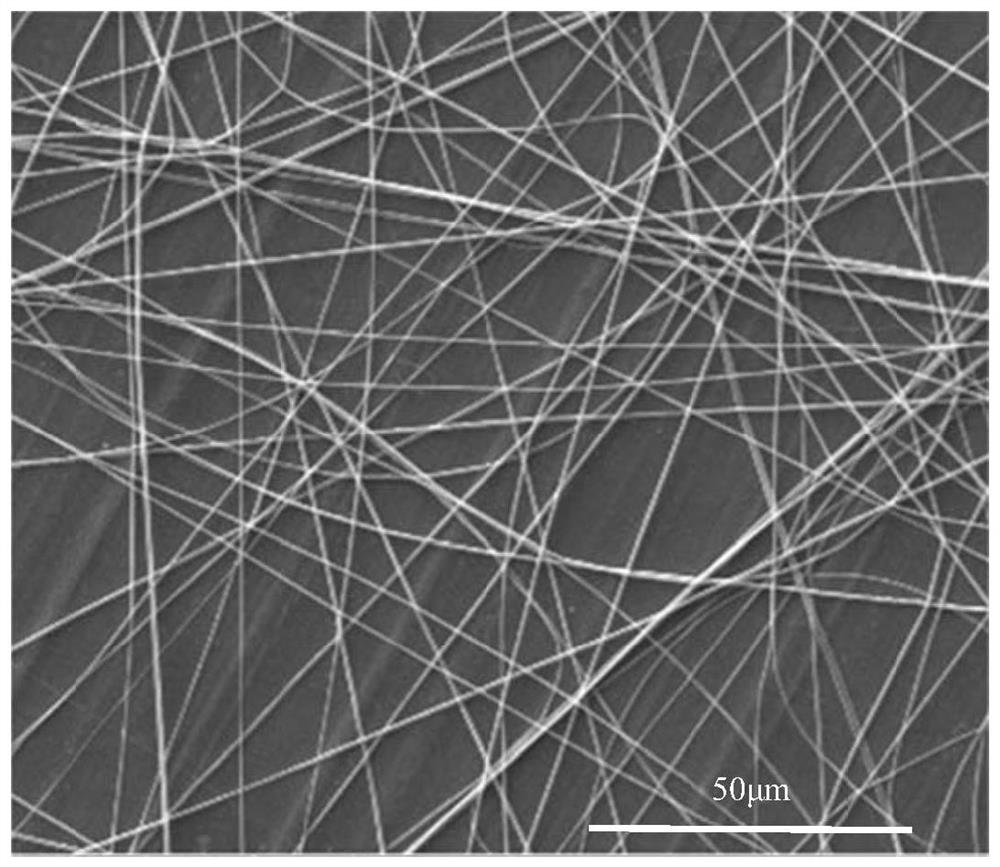

Image

Examples

Embodiment 1

[0037] Step 1: Weigh 5g of PVB and add it to 200ml of hot water at 70°C for washing. After washing, centrifuge and dehydrate to remove the supernatant, repeat washing for 5 times, dry in vacuum at 75°C for 8 hours, grind and sieve to obtain pretreated PVB powder ;

[0038] Step 2: Weigh 0.24g of PVP powder, weigh 0.56g of the PVB powder in step 1 and dissolve them in 5g of absolute ethanol, stir for 2h to obtain a uniformly mixed polymer spinning solution;

[0039] Step 3: Weigh 0.2g of blue copper peptide and dissolve in 0.1g of ultrapure water and stir until completely dissolved, weigh 0.1g of borneol and 50mg of organic polyquaternium-73, dissolve in 3.65g of absolute ethanol and stir until completely dissolved;

[0040] Step 4: Add all the solution in step 3 to the spinning solution prepared in step 2, and keep stirring until the solution is completely mixed to obtain 8 wt% of the polymer solute, 2 wt% of azurite peptide, and 1 wt% of borneol. Quaternary ammonium salt-73...

Embodiment 2

[0046] Step 1: Weigh 5g of PVB and add it to 200ml of hot water at 70°C for washing. After washing, centrifuge to remove the supernatant, repeat washing for 3 times, dry in vacuum at 75°C for 6 hours, grind and sieve to obtain pretreated PVB powder ;

[0047] Step 2: Weigh 0.6g of PVP powder, weigh 0.9g of the PVB powder in step 1 and dissolve them in 5g of absolute ethanol, stir for 2h to obtain a uniformly mixed polymer spinning solution;

[0048] Step 3: Weigh 0.1g of blue copper peptide and dissolve in 0.1g of ultrapure water and stir until completely dissolved, weigh 50mg of borneol and 50mg of organic polyquaternium-73 and dissolve in 3.1g of absolute ethanol and stir until completely dissolve;

[0049] Step 4: Add all the solution in step 3 to the spinning solution prepared in step 2, and continue to stir until the solution is completely mixed to obtain a polymer solute with a mass of 15wt%, a blue copper peptide with 1wt%, and borneol with 0.5wt%. Organic Polyquatern...

Embodiment 3

[0054] Step 1: Weigh 5g of PVB and add it to 200ml of hot water at 75°C for water washing. After washing, centrifuge to remove the supernatant, repeat washing for 5 times, vacuum dry at 75°C for 6 hours, grind and sieve to obtain pretreated PVB powder ;

[0055] Step 2: Weigh 0.3g of PVP powder, weigh 0.7g of the PVB powder in step 1 and dissolve them in 5g of absolute ethanol, stir for 2h to obtain a uniformly mixed polymer spinning solution;

[0056] Step 3: Weigh 60mg of blue copper peptide and dissolve in 0.1g of ultrapure water and stir until completely dissolved, weigh 0.1g of borneol and 50mg of organic polyquaternium-73 and dissolve in 3.49g of absolute ethanol and stir until completely dissolve;

[0057] Step 4: Add all the solution in step 3 to the spinning solution prepared in step 2, and continue to stir until the solution is completely mixed to obtain 10wt% of the polymer solute, 0.6wt% of azurite peptide, and 1wt% of borneol, organic Polyquaternium-73 is 0.5wt%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com