Synthesis method for converting glyoxal into glyoxylic acid through photoelectrocatalytic oxidation

A technology of photoelectric catalysis and synthesis method, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., to achieve the effects of mild reaction conditions, environmental friendliness and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

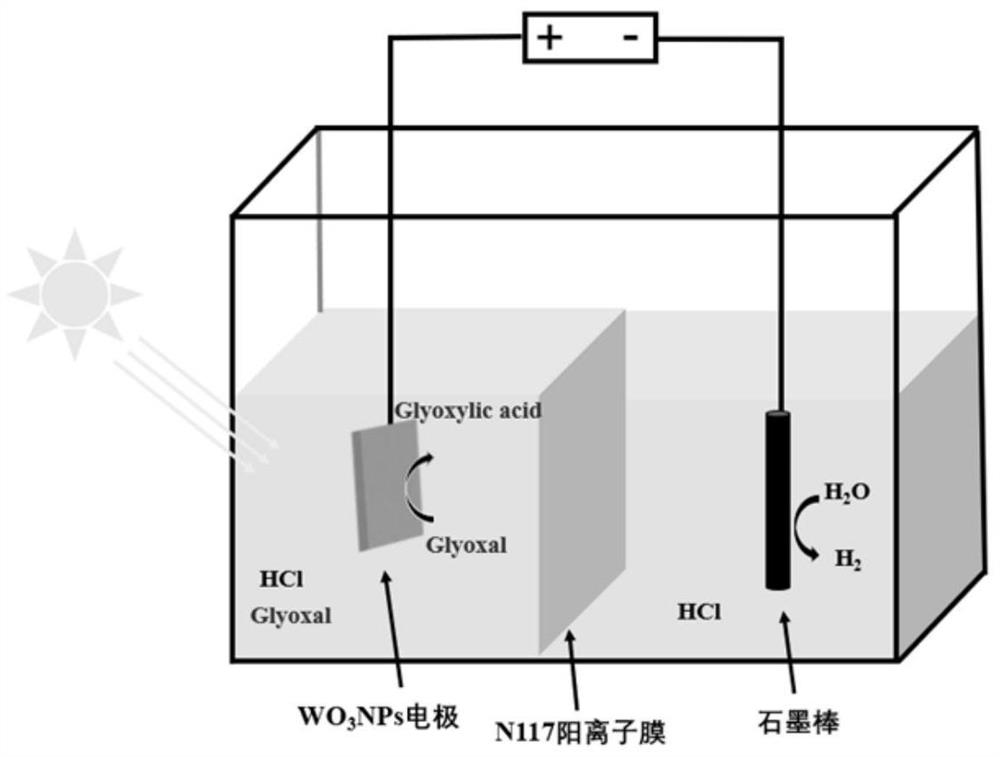

[0032] Embodiment 1: Using WO with nanosheet (NPs) array structure 3 Materials as photoanodes for photocatalytic oxidation of glyoxal to glyoxylic acid

[0033] (1) Preparation of WO by hydrothermal method 3 NPs photoanode

[0034] Take FTO conductive glass (2*15*50mm) as the carrier, soak in 25mL aqueous solution containing sodium tungstate and citric acid (the molar ratio of sodium tungstate and citric acid is 19:37, the concentration of sodium tungstate is 0.018mol / L) In the solution, the pH value of the solution was adjusted to 7 with 9.5% hydrochloric acid. The hydrothermal reaction was carried out at 120°C for 12h, then filtered, washed, and fired at 450°C for 2h, and the WO with nanosheet structure array was obtained on the FTO conductive glass substrate. 3 Photoanode (denoted as FTO / WO 3 NPs).

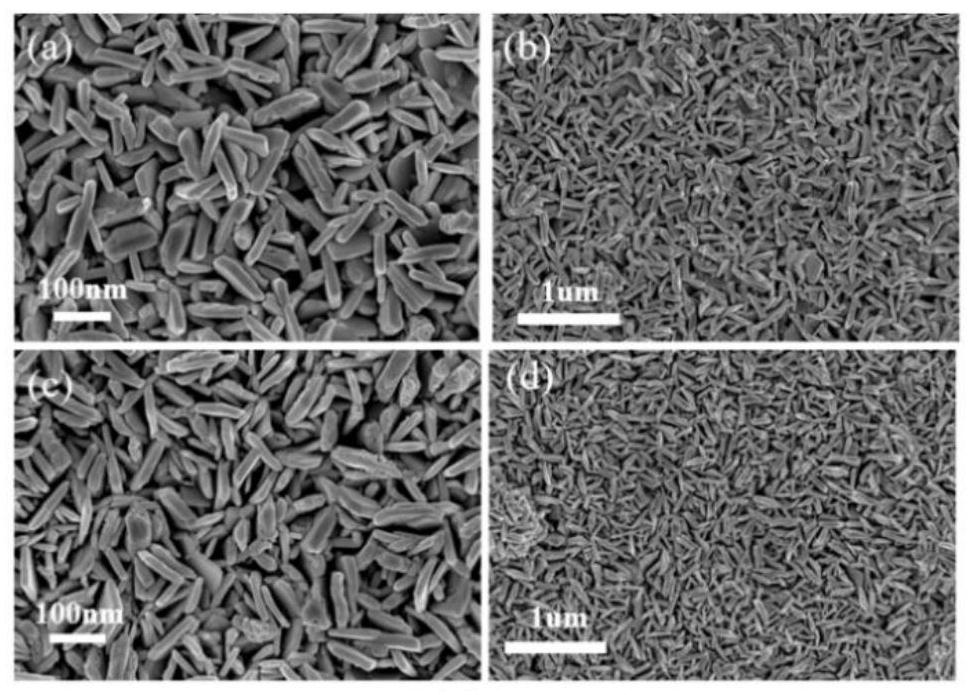

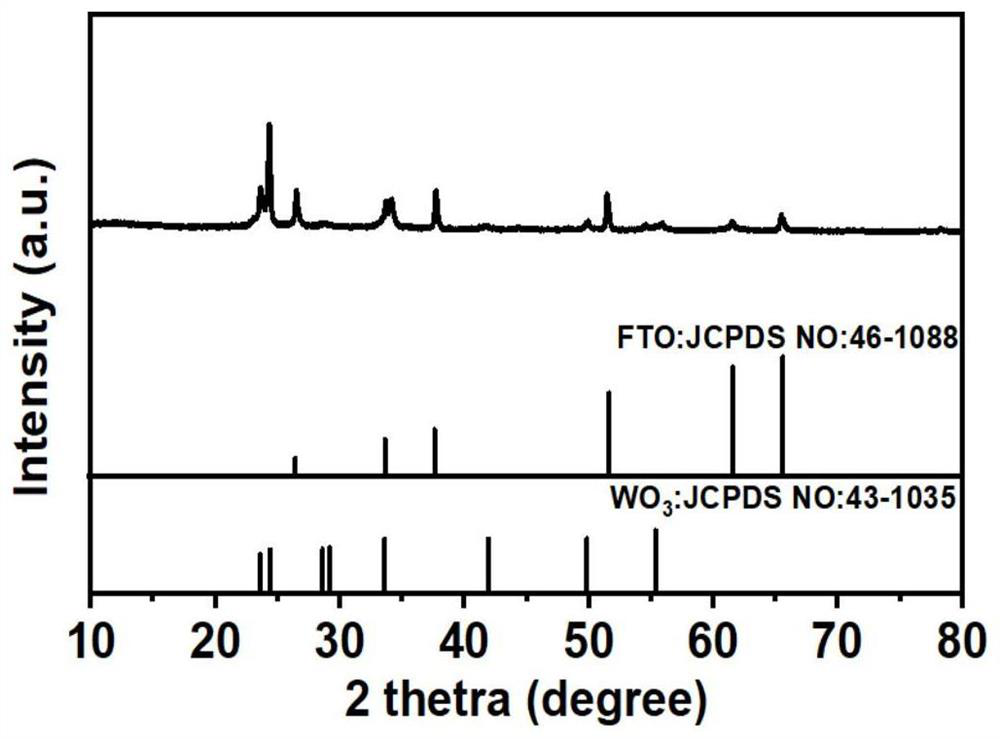

[0035] figure 1 (a), (b) are the prepared FTO / WO 3 Scanning electron microscope image of NPs, it can be seen that its microscopic morphology is WO with high-density verti...

Embodiment 2

[0041] Embodiment 2: Using TiO with nanorod (NBs) structure array 2 Materials as photoanodes for photocatalytic oxidation of glyoxal to glyoxylic acid

[0042] (1) Preparation of TiO by hydrothermal method 2 NBs photoanode

[0043] Using FTO conductive glass as a carrier, soak it in 24.35mL aqueous hydrochloric acid solution containing tetrabutyl titanate (the molar ratio of tetrabutyl titanate to HCl is 1:340.32, and the concentration of tetrabutyl titanate is 0.04mol / L). Perform hydrothermal reaction at 150°C for 6 hours, then filter, wash with absolute ethanol, and burn in air at 450°C for 3 hours to obtain TiO on the FTO conductive glass substrate 2 NBs photoanode (denoted as FTO / TiO 2 NBs).

[0044] Figure 5 For the prepared FTO / TiO 2 Scanning electron microscope image of NBs, it can be seen that its microscopic morphology is vertical nanorod TiO on FTO substrate 2 Arrange evenly.

[0045] (2) with TiO 2 NBs material as photoanode for photocatalytic oxidation of...

Embodiment 3

[0048] Embodiment 3: Using BiVO with nanosheet structure 4 Materials as photoanodes for photocatalytic oxidation of glyoxal to glyoxylic acid

[0049] (1) Preparation of BiVO by precipitation method 4 Photoanode:

[0050] Take FTO conductive glass as the carrier, soak in 70mL ethanol aqueous solution containing potassium iodide, bismuth nitrate pentahydrate and p-benzoquinone (the volume ratio of ethanol: water is 2:5, the concentration ratio of potassium iodide, bismuth nitrate pentahydrate and p-benzoquinone is 4: 4:23, potassium iodide concentration 0.04mol / L), apply a voltage of -0.1V vs Ag / AgCl, take it out after 5 minutes of electrodeposition, rinse and dry; The concentration ratio of vanadyl acetonate and dimethyl sulfoxide is 1:35, the concentration of vanadyl acetylacetonate is 0.4mol / L) dropwise on the surface of the material, and then burnt by air at 450°C for 2h, stirred and soaked in 1mol / L NaOH solution for 0.5h, washed , after drying, BiVO was obtained on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com