MEMS infrared light source and preparation method thereof

An infrared light source, filamentary technology, applied in optics, light guides, optical components, etc., can solve the problems of limiting thickness, interface adhesion, affecting the practical application of thin films, etc., to reduce internal stress, improve DLC interface adhesion, low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The solutions of the present invention will be explained below in conjunction with examples. Those skilled in the art will understand that the following examples are only for illustrating the present invention and should not be considered as limiting the scope of the present invention. If no specific technique or condition is indicated in the examples, it shall be carried out according to the technique or condition described in the literature in this field or according to the product specification. The reagents or instruments used were not indicated by the manufacturer, and they were all commercially available conventional products. The experimental methods used are conventional methods unless otherwise specified.

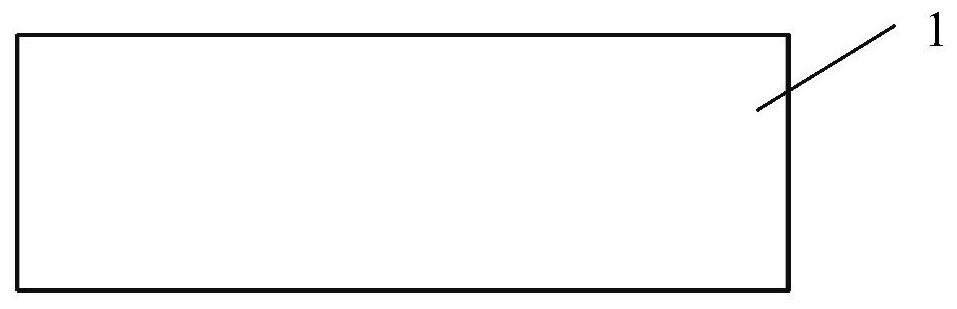

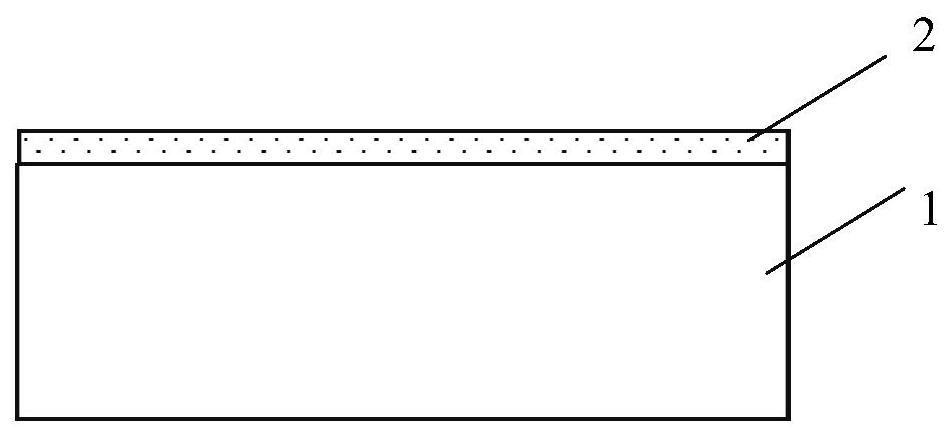

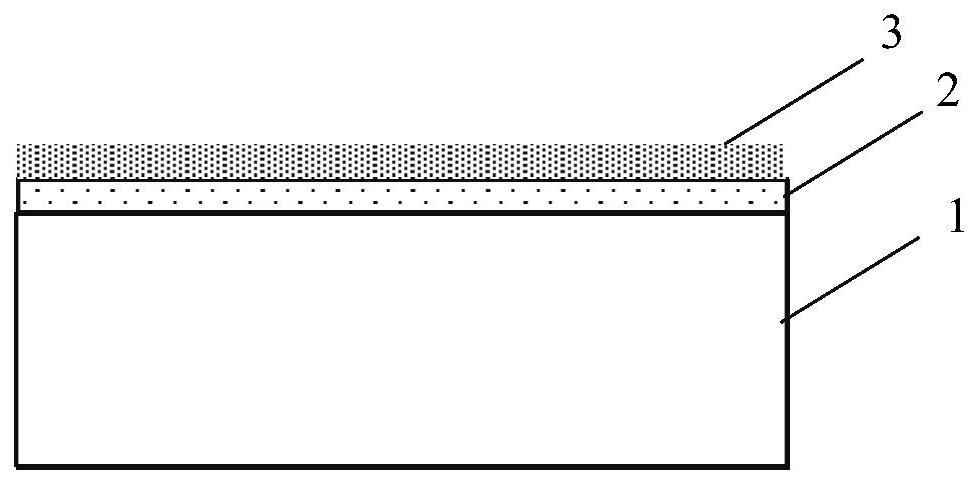

[0041] Such as Figure 1-1~1-10 Shown, for the preparation method of a kind of MEMS infrared light source provided by the present invention, described preparation method comprises the following steps:

[0042] (1) Picture 1-1 It shows the oriented monocry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com