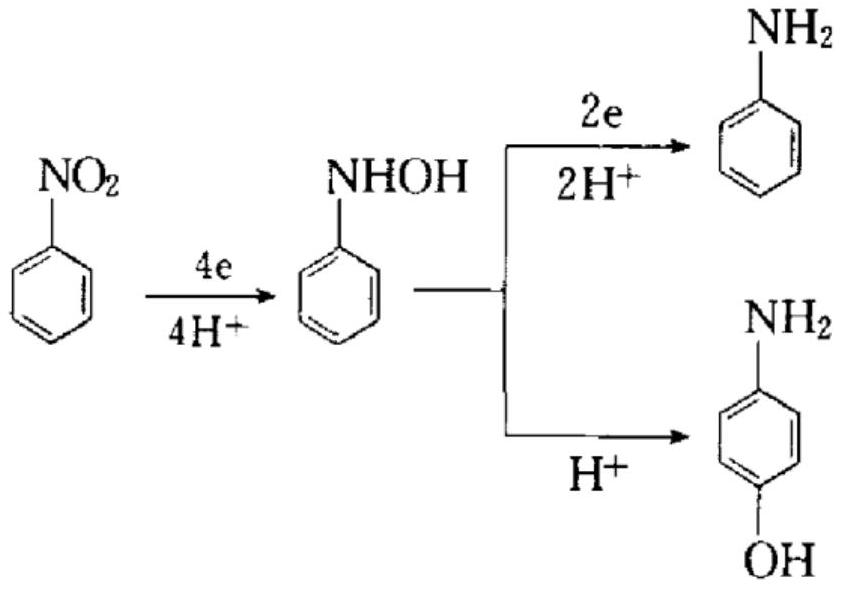

Electrode material for synthesizing p-aminophenol by electrolyzing nitrobenzene, preparation method and application thereof

A technology of p-aminophenol and electrode materials, applied in electrodes, electrolytic components, electrolytic processes, etc., can solve the problems of excessive reduction of intermediate phenylene, low reaction selectivity, low solubility, etc., and achieve high total yield and dangerous operation low cost and low equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Preparation of electrode materials for electrolysis of nitrobenzene to synthesize p-aminophenol:

[0075] (1) Put 38g of spherical copper metal particles (about 6,000 pieces) with a diameter of 0.3mm into acetone and ultrasonicate for 20min to remove surface grease;

[0076] Get 100g tetrabutyl titanate, 0.5g acetylacetone, 39.1g concentrated hydrochloric acid (37wt%), 500g deionized water and 1000g absolute ethanol and mix evenly, wherein, tetrabutyl titanate, acetylacetone, concentrated hydrochloric acid (37wt%) ), deionized water, and absolute ethanol in a mixing mass ratio of 1:0.005:0.4:5:10, then add 0.8g niobium pentachloride and 2.37g anhydrous copper chloride therein, and stir to obtain a sol solution.

[0077] Place the degreased copper particles in a centrifuge tube, add 7.6g of sol solution, mix the sol solution with the degreased copper metal particles at a mass ratio of 0.2:1, spin coat in a centrifuge for 20s, and spin the sol at 2000r / min The solution w...

Embodiment 2

[0080] Preparation of electrode materials for electrolysis of nitrobenzene to synthesize p-aminophenol:

[0081] (1) Put 22.5g of spherical copper metal particles (about 32,000 pieces) with a diameter of 0.1mm into acetone and ultrasonicate for 15 minutes to remove surface grease;

[0082] Get 100g tetrabutyl titanate, 0.4g acetylacetone, 30g concentrated hydrochloric acid (33wt%), 400g deionized water and 1000g absolute ethanol and mix evenly, wherein, tetrabutyl titanate, acetylacetone, concentrated hydrochloric acid (33wt%) , deionized water, absolute ethanol mixing mass ratio is 1: 0.004: 0.3: 4: 10, then adds 1.6g niobium pentachloride and 1.58g anhydrous cupric chloride wherein, stirs and makes sol solution;

[0083] Place the degreased copper particles in a centrifuge tube, add 6.8g sol solution, mix the sol solution with the degreased copper metal particles at a mass ratio of 0.3:1, spin coat in a centrifuge for 10s at a speed of 5000r / min, and dissolve the sol The so...

Embodiment 3

[0086] Preparation of electrode materials for electrolysis of nitrobenzene to synthesize p-aminophenol:

[0087] (1) Put 70.4g of spherical copper metal particles (about 25,000 pieces) with a diameter of 0.2mm into acetone and ultrasonicate for 30min to remove surface grease;

[0088] Get 100g tetrabutyl titanate, 0.6g acetylacetone, 60g concentrated hydrochloric acid (37wt%), 1000g deionized water and 1500g absolute ethanol and mix evenly, wherein, tetrabutyl titanate, acetylacetone, concentrated hydrochloric acid (37wt%) , deionized water, dehydrated ethanol mixed mass ratio is 1: 0.006: 0.6: 10: 15, then adds 2.4g niobium pentachloride and 1.2g anhydrous cupric chloride wherein, stirs and makes sol solution;

[0089] Place the degreased copper particles in a centrifuge tube, add 28.1g of sol solution, mix the sol solution with the degreased copper metal particles at a mass ratio of 0.4:1, spin coat in a centrifuge for 15s at a speed of 3000r / min, and dissolve the sol The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com