Wireless passive resistance corrosion monitoring method and system

A corrosion monitoring, wireless passive technology, applied in the field of wireless passive resistance probe pipeline corrosion detection, can solve the problems of waste of manpower and material resources, occupying space, unsuitable pipelines, etc., and achieve the effect of occupying a small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

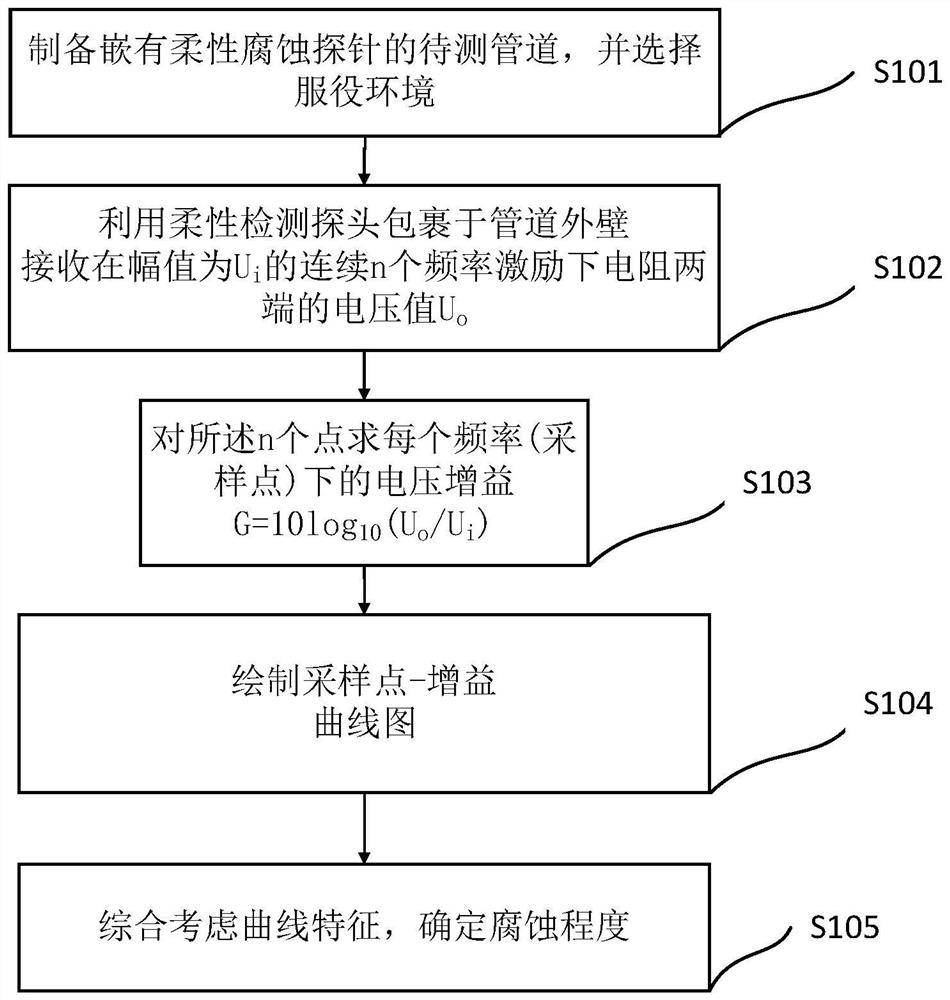

[0038] refer to Figure 1 to 6 , The corrosion resistance of passive wireless monitoring method, comprising the following steps: S101, the test preparation of the flexible conduit is attached to the corrosion probe, and selecting service environment.

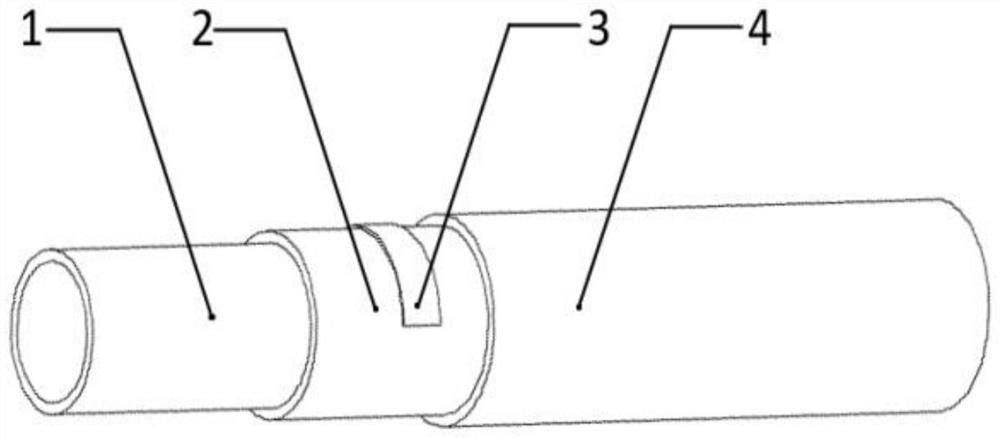

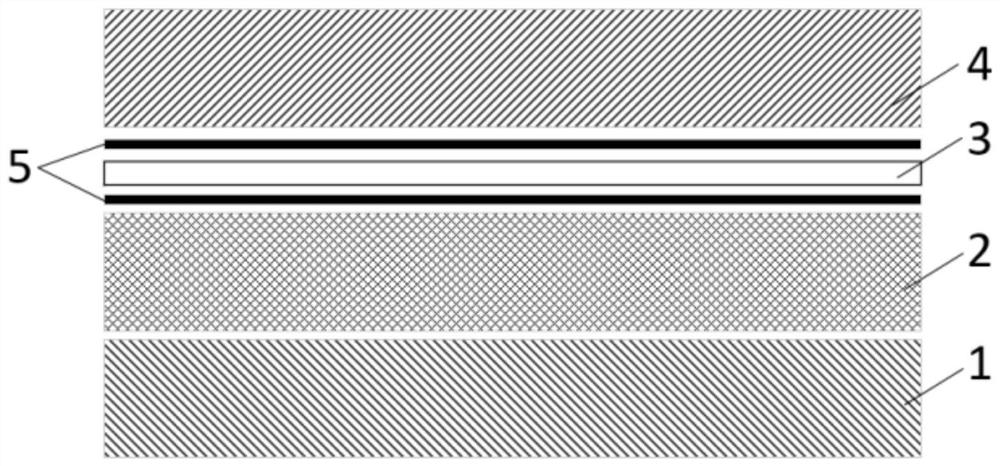

[0039] Specifically, the configuration of the flexible corrosion probe comprising inductor L R , For detection of the probe tip and the inductor L T Mutual inductance of the coil is formed, a passive internal corrosion wireless information acquisition. And a special plurality of resistance as the sensing element. The probe is a flexible tube pre-fitted to the outer pipe 4 and the protective layer between the reinforcing layer 2, the resistance can be gradually increased with its plurality of pipeline corrosion resistance will be.

[0040] S102, the flexible probe cover detection position of the tube to be detected, in order to determine a fixed mutual inductance coil pitch H 1 Collected close to the magnitude U i Under continuous n f...

Embodiment 2

[0049] Corrosion resistance probe based wireless passive detection method according to a first embodiment of the duct, the present embodiment gives a mutual inductance winding pitch H 1 And excitation frequency, sampling points for the experimental embodiment of the method of particular value to verify the validity of the method.

[0050] Analysis tool used for the Network Analyzer, the excitation frequency is 1kHz to 12MHz, equidistant variation acquiring the frequency range between 1000 sampling points frequency (f 1 2 n-1 n ), N = 1000 (f 1 = 1000Hz, f 2 = 13011Hz, f 3 = 25022Hz, ...... f 1000 = 11.9MHz). Such as Image 6 Indicated. To facilitate verification experiment between the detection probe and the probe body is placed plexiglass embedded resistor to simulate the outer protective layer pipe, and the resistance change due to corrosion of the variable resistor analog selection, select the variable resistance 5, respectively 1.6 Ω, 4.6Ω, 12Ω, 21Ω, 28.9Ω.

[0051] according t...

Embodiment 3

[0054] A wireless corrosion monitoring method of a passive resistor, comprising the steps of:

[0055] S101, the test preparation of the flexible conduit is embedded corrosion probe;

[0056] S102, wrapping using a flexible probe to detect the magnitude of the reception pipe wall U i Under continuous n frequency excitation voltage U across the resistance o ;

[0057] S103, seeking voltage gain at each frequency of the n points, G = 10log 10 (U o / U i );

[0058] S104, rendering sampling points - graph of gain;

[0059] S105, considering the characteristic curve, determine the extent of corrosion.

[0060] Wherein, when the position of said probe cover corroded constant period, receives the detection probe R 1 Both ends of the detection signals, comprising: T in each etching cycle i Obtaining respective average excitation frequency (f 1 2 n-1 n ) Probe at a resistor R 1 The detection signal voltage value (U generated across 1i U 2i , ......, U (n-1)i U ni ), The gain of rendering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com