Nonlinear nano hybrid material based on vanadium carbide and molybdenum disulfide and preparation method

A nanometer hybrid material, vanadium carbide nanotechnology, applied in chemical instruments and methods, molybdenum oxide/molybdenum hydroxide, carbon compounds, etc., can solve problems such as restricted use, and achieve the effect of improving nonlinear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

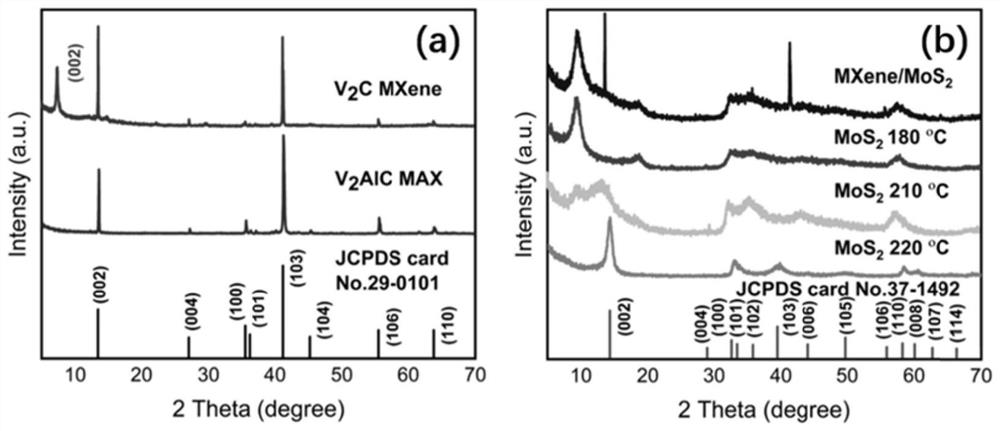

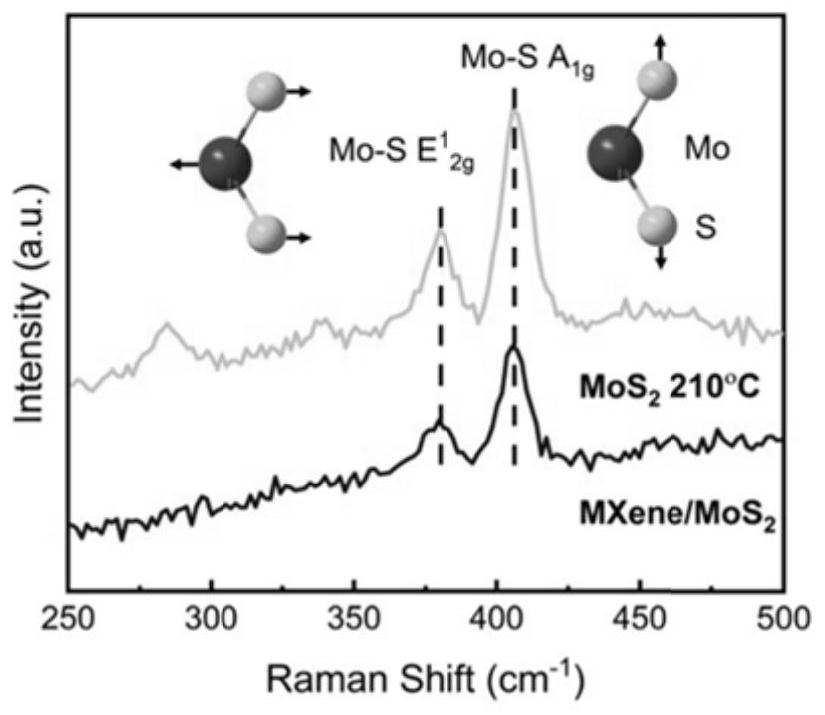

[0037] The preparation method of the nonlinear nano-hybrid material based on vanadium carbide and molybdenum disulfide comprises the following steps:

[0038] (1) Vanadium aluminum carbide (V 2 AlC) is etched in hydrogen fluoride solution to obtain vanadium carbide (V 2 C), stripping vanadium carbide in tetramethylammonium hydroxide to obtain (smaller) vanadium carbide nanosheets;

[0039] (2) Dissolve the sulfur source and the molybdenum source in deionized water, stir (preferably adopt the mode of vigorous stirring) to form a homogeneous solution, add a surfactant, add vanadium carbide nanosheets, disperse evenly, and synthesize them by high-temperature hydrothermal method to obtain the obtained The described nonlinear nanohybrid material based on vanadium carbide and molybdenum disulfide.

[0040]In the invention, the vanadium aluminum carbide is first etched in a hydrogen fluoride solution, and then stripped in tetramethyl ammonium hydroxide. Then, the raw materials for...

Embodiment 1

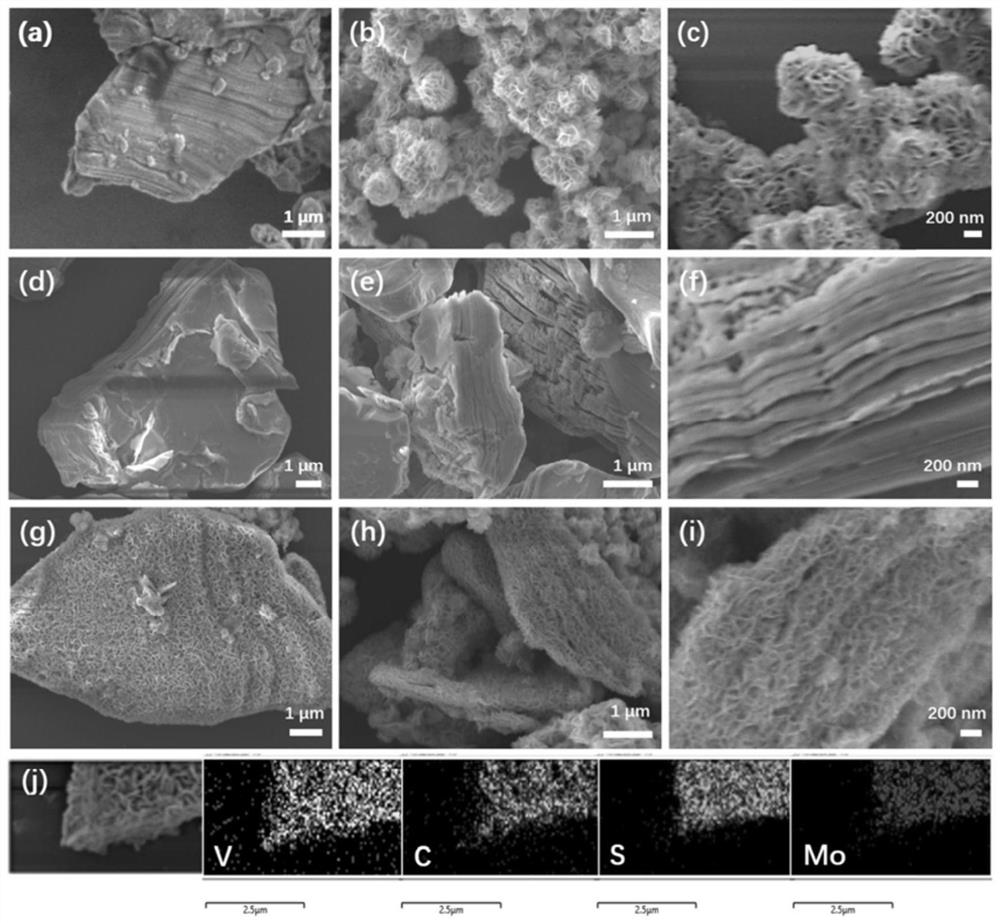

[0047] Preparation of nonlinear nano-hybrid materials based on vanadium carbide and molybdenum disulfide (see Figure 6 ):

[0048] 20mL of hydrogen fluoride solution (40%) was deoxygenated, nitrogen was bubbled for 20min, and then 1g of vanadium aluminum carbide was added, the etching reaction temperature was 35°C, and the etching reaction time was 96h. After the reaction, add deionized water to wash, centrifuge at 3000rpm to obtain solid powder until the pH of the supernatant is greater than 6, and collect solid vanadium carbide after drying. The vanadium carbide obtained by etching was stripped in 10 mL of tetramethylammonium hydroxide in a nitrogen environment, reacted at room temperature for 24 hours, and centrifuged to collect vanadium carbide nanosheets with smaller nanometer size.

[0049] 0.7105 g of thiourea and 0.3621 g of ammonium heptamolybdate tetrahydrate were dissolved in 21.8 mL of deionized water, and stirred vigorously with a magnet until a homogeneous solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com