Preparation method of porous network composite material with shielding and sound absorption functions

A composite material and porous network technology, which is applied in the field of preparation of porous network composite materials, can solve the problems of low mechanical properties of composite materials, difficult application effect, unenvironmental protection, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

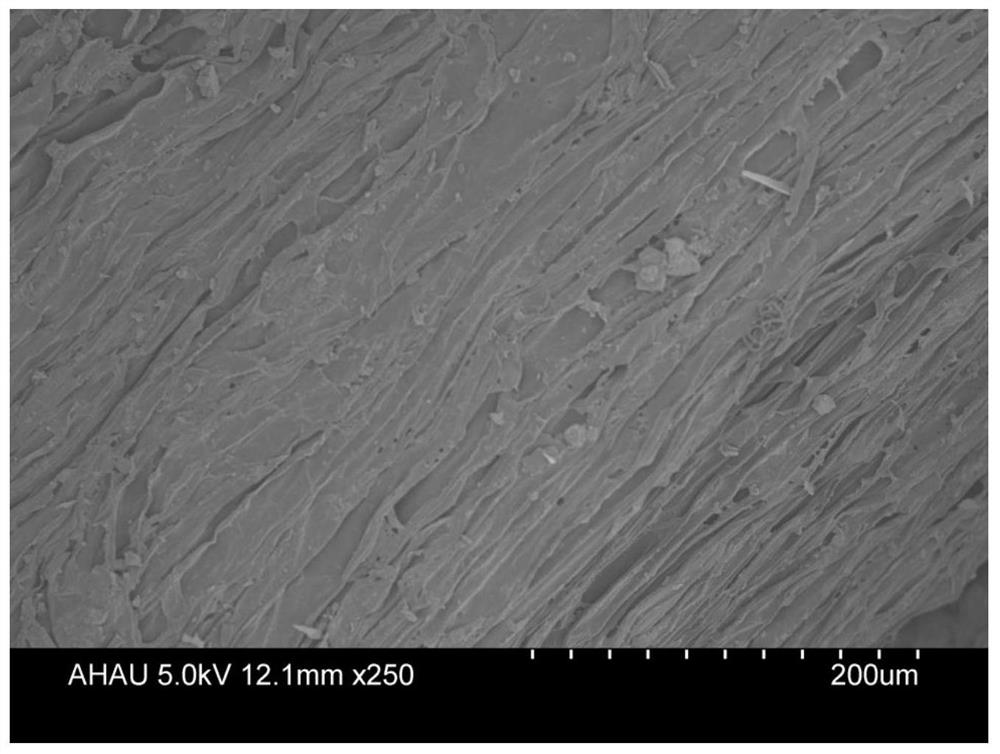

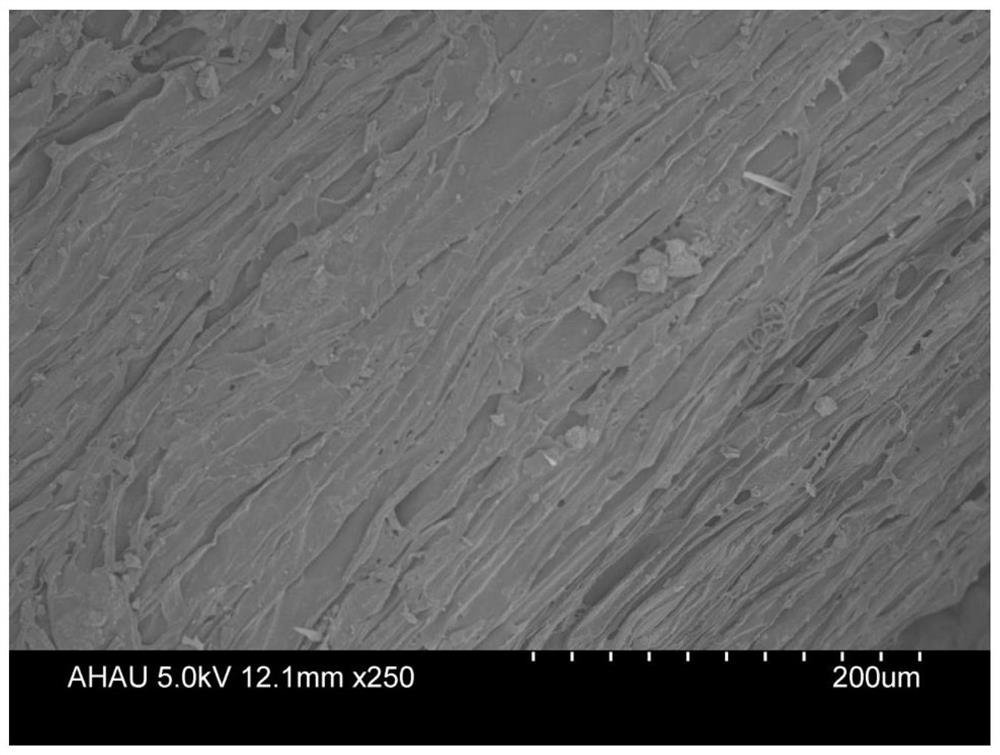

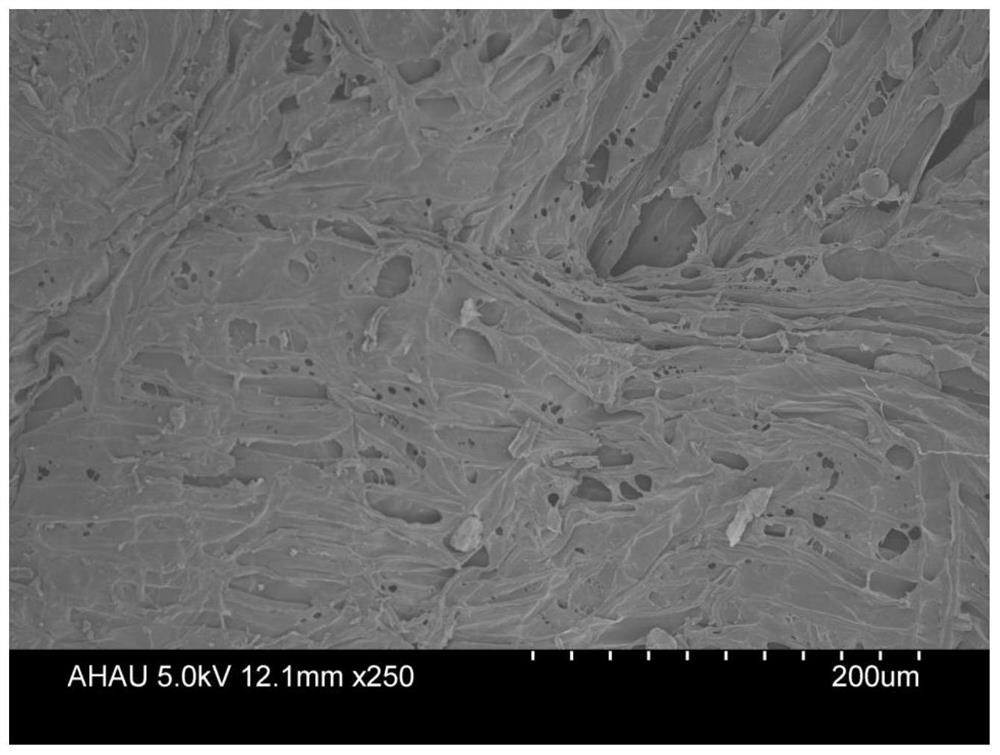

Image

Examples

Embodiment 1

[0042] A porous network composite material with both shielding and sound absorption functions in this embodiment is used for home decoration materials, and its preparation method is as follows:

[0043] (1) Preparation of Pine Cone Charcoal

[0044] a. The agricultural and forestry waste pine cones are preliminarily crushed; in order to reduce the dirt and impurities in the pine cones, after crushing, the pine cones are soaked in tap water for 24 hours, and then rinsed repeatedly with running water for 2 to 4 times; after natural drying, The rice husks were dried at 105°C for 24 hours in a blower drying oven to keep the water content below 3%. Finally, the pine cones were crushed with a universal grinder and screened with a 100-mesh sieve to obtain 100-mesh pine cone powder.

[0045] b. Put the pine cone powder into a tube furnace, raise the temperature to 800°C at a heating rate of 10°C / min, and keep the temperature constant for 1 hour, using high-purity nitrogen as a protect...

Embodiment 2

[0058] A porous network composite material with both shielding and sound absorption functions in this embodiment is used for home decoration materials, and its preparation method is as follows:

[0059] (1) Preparation of Pine Cone Charcoal

[0060] a. The agricultural and forestry waste pine cones are preliminarily crushed; in order to reduce the dirt and impurities in the pine cones, after crushing, the pine cones are soaked in tap water for 24 hours, and then rinsed repeatedly with running water for 2 to 4 times; after natural drying, The rice husks were dried at 105°C for 24 hours in a blower drying oven to keep the water content below 3%. Finally, the pine cones were crushed with a universal grinder and screened with a 100-mesh sieve to obtain 100-mesh pine cone powder.

[0061] b. Put the pine cone powder into a tube furnace, raise the temperature to 800°C at a heating rate of 10°C / min, and keep the temperature constant for 1 hour, using high-purity nitrogen as a protect...

Embodiment 3

[0075] A porous network composite material with both shielding and sound absorption functions in this embodiment is used for home decoration materials, and its preparation method is as follows:

[0076] (1) Preparation of Pine Cone Charcoal

[0077] a. The agricultural and forestry waste pine cones are preliminarily crushed; in order to reduce the dirt and impurities in the pine cones, after crushing, the pine cones are soaked in tap water for 24 hours, and then rinsed repeatedly with running water for 2 to 4 times; after natural drying, The rice husks were dried at 105°C for 24 hours in a blower drying oven to keep the water content below 3%. Finally, the pine cones were crushed with a universal grinder and screened with a 100-mesh sieve to obtain 100-mesh pine cone powder.

[0078] b. Put the pine cone powder into a tube furnace, raise the temperature to 800°C at a heating rate of 10°C / min, and keep the temperature constant for 1 hour, using high-purity nitrogen as a protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com