Atom-doped modified double-shell integral hollow catalyst as well as preparation method and application thereof

A monolithic catalyst technology, which is applied in the fields of comprehensive resource utilization and environmental pollution control, can solve the problems of molecular sieve catalyst poisoning, and achieve the effects of high and low temperature catalytic activity, sufficient surface active oxygen components, and high catalytic redox characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] A method for preparing an atom-doped modified double-shell monolithic hollow catalyst, characterized in that it comprises the following steps:

[0075] S1: Preparation of organic carbon microspheres

[0076] S101: Mix the soluble starch and glucose according to the ratio, heat and stir, transfer to the reaction kettle, and perform dynamic hydrothermal reaction to obtain the mixture A;

[0077] S102: After the mixture A is cooled, an organic solid product is obtained after ultrasonication, filtration, and drying, which are organic carbon microspheres;

[0078] S2: Preparation of organic carbon microspheres coated with N-ZSM-5 precursor material

[0079] S201: Add deionized water, sodium hydroxide, tetrapropylammonium hydroxide or tetrapropylammonium bromide, ethanol and polyquaternium into the reaction kettle in sequence according to the proportion and order, and heat and mix with ultrasonic to obtain the mixture B ;

[0080] S202: adding silica sol, organic salt and ...

Embodiment 1

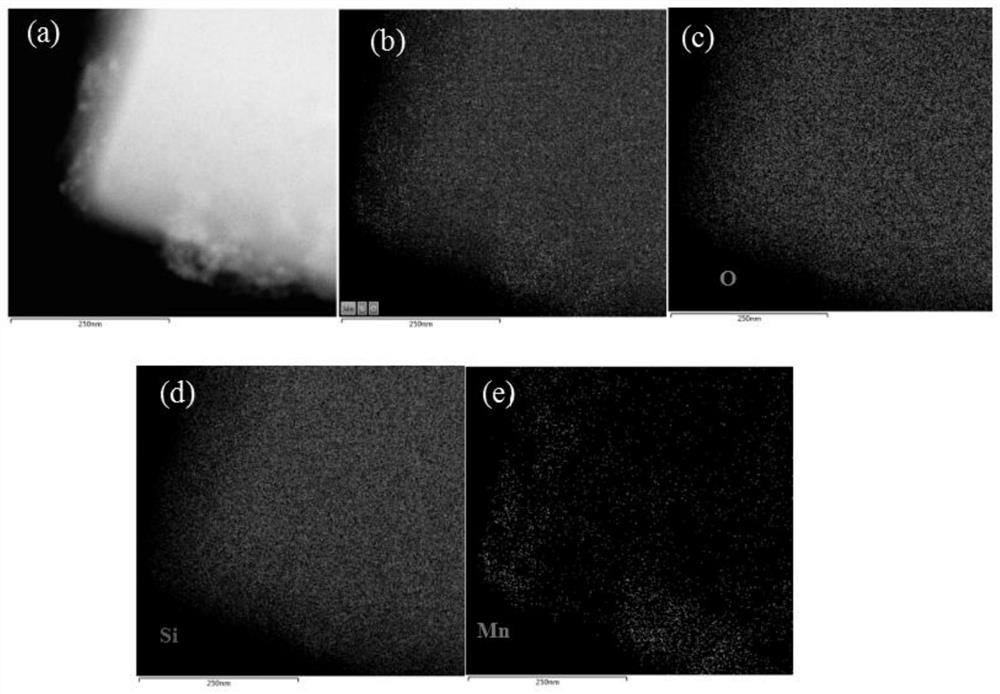

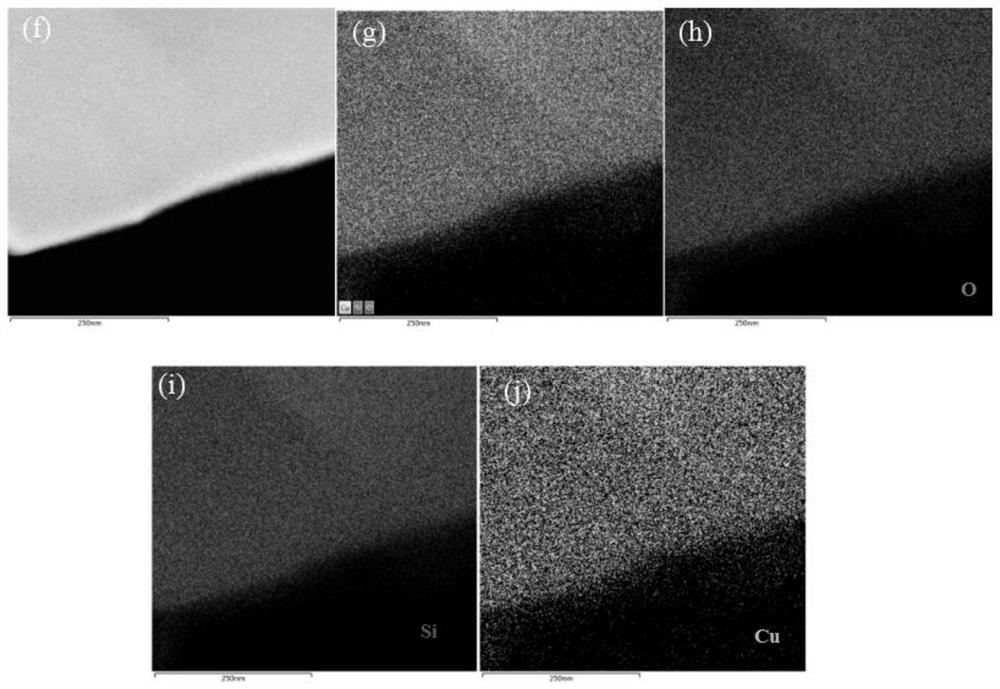

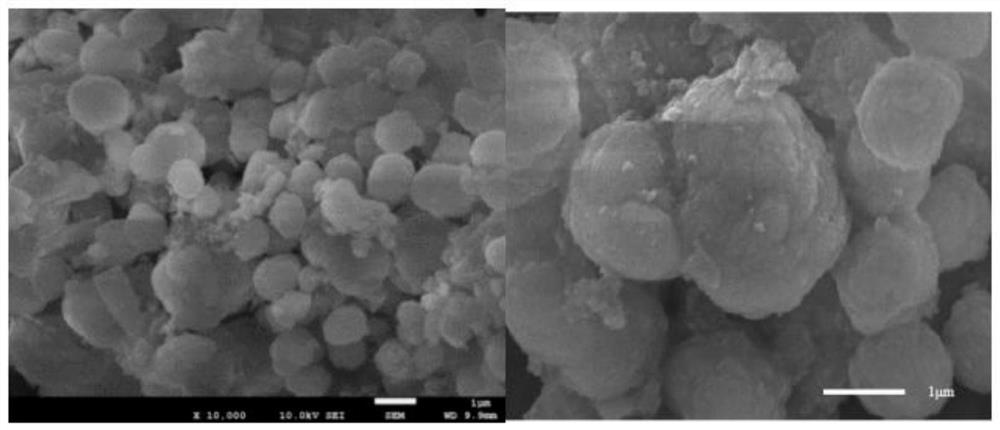

[0090] Layered coating overall crystallization technology

[0091] The method is to convert soluble starch and glucose into carbon microspheres after hydrothermal; Carbon microspheres coated with N-ZSM-5 precursor material were prepared under hydrothermal; finally, the composite carbon microspheres were added to the mixed solution solution with metal-doped M-ZSM-5 precursor, and heated under ultrasonic Under the conditions of mixing, microwave and thermal radiation, after filtering, washing, drying and roasting, the N-ZSM-5@M-ZSM-5 monolithic hollow catalyst was finally prepared, and N and M represent Fe, Cu, Mn, Ni , Co, Ti and other transition metal elements.

[0092] When implementing it:

[0093] Mix soluble starch and glucose in a mass ratio (3-5): 1, heat and ultrasonically stir for a certain period of time, wherein the ultrasonic power is 100-300W, the ultrasonic time is 30-60min, and the heating temperature is 40-70°C. After being transferred into the reactor, the dyn...

Embodiment 2

[0100] Ultrasonic Heating Assisted Microwave Combined Thermal Radiation Gel Crystallization

[0101] The method is to add a certain amount of deionized water, sodium hydroxide, tetrapropylammonium hydroxide or tetrapropylammonium bromide ( TPAOH / TPABr), ethanol, polyquaternium salt, silica sol and transition metal salt components, ultrasonically heated and mixed for a certain period of time, heated and stirred to gel; the gel was transferred to the reaction kettle, combined with microwave After crystallization by heat radiation method for a certain period of time, the catalyst is obtained by washing, drying and calcining.

[0102] When implementing it:

[0103] First, the obtained carbon microspheres coated with N-ZSM-5 precursor material were added to deionized water, sodium hydroxide, tetrapropylammonium hydroxide or tetrapropylammonium bromide (TPAOH / TPABr), ethanol , polyquaternium salt, silica sol and transition metal salt components in the mixed solution, wherein the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com