Starch modified PBAT/PLA biodegradable plastic film and preparation method thereof

A biodegradation and starch modification technology, applied in the field of polymer materials, can solve the problems of weak mechanical ability of thin film materials, limited application range, complicated process, etc., and achieve the effects of low production cost, short operation time and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

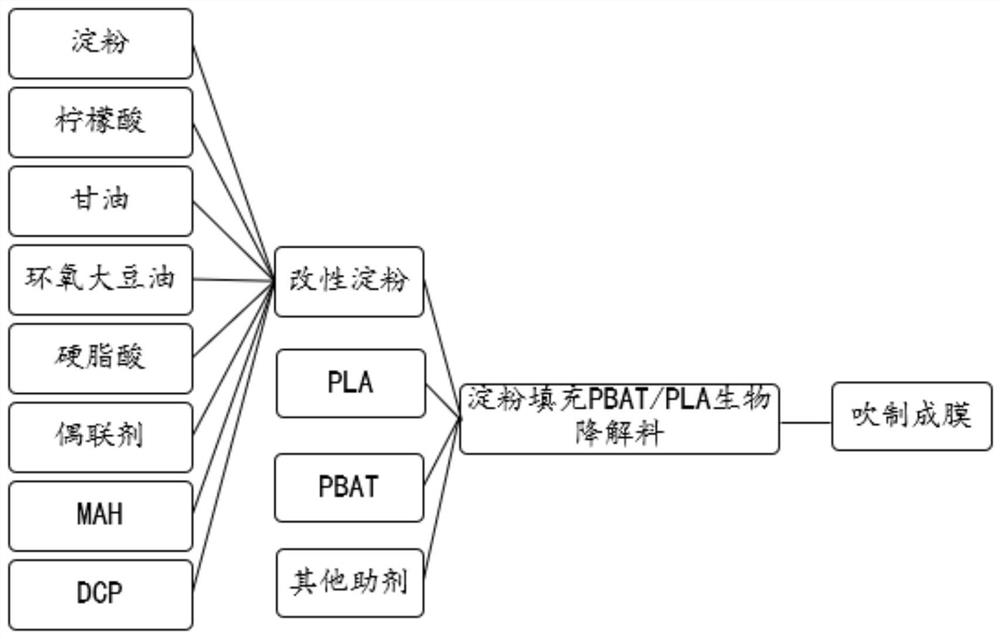

Method used

Image

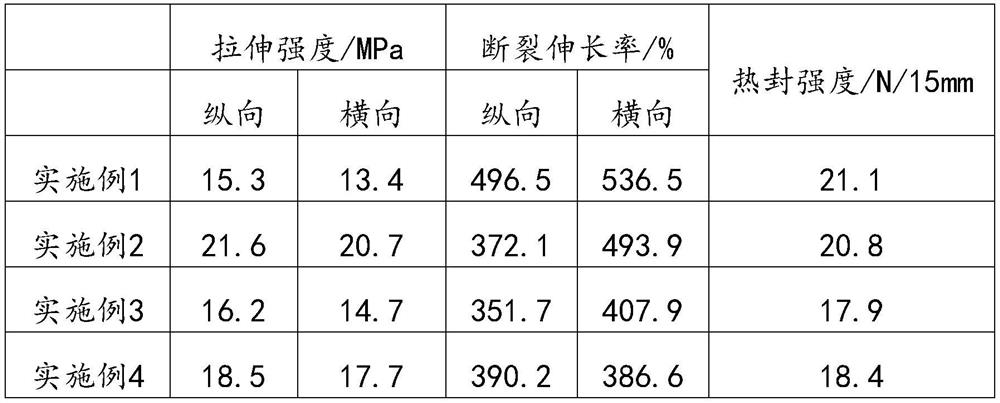

Examples

Embodiment 1

[0048] A starch-modified PBAT / PLA biodegradable plastic film, in parts by weight, comprises the following components:

[0049] 60 parts of PBAT, 20 parts of PLA, 20 parts of modified starch, 1 part of MDI, 2 parts of PEG400, 0.6 parts of erucamide, 0.5 parts of antioxidant 1010, 2-(2-hydroxy-5-methylphenyl)benzene 0.5 part of triazole, 0.1 part of ADR4468.

[0050] The preparation method is:

[0051] S1. Prepare modified starch, the specific components are: 100 parts of starch with a water content of 8-10%, 0.5 parts of epoxidized soybean oil, 20 parts of glycerin, 10 parts of citric acid, 1 part of stearic acid, coupling agent KH560 2 5 parts, 5 parts of maleic anhydride, 0.5 parts of cumene peroxide.

[0052] Weigh the starch, glycerin and citric acid in proportion, stir at room temperature for 30 minutes, add stearic acid and coupling agent, stir at room temperature for 5 minutes, then add maleic anhydride and cumene peroxide, and stir at room temperature for 5 minutes to...

Embodiment 2

[0058] A starch-modified PBAT / PLA biodegradable plastic film, in parts by weight, comprises the following components:

[0059] 60 parts of PBAT, 30 parts of PLA, 10 parts of modified starch, 5 parts of PLA-g-MAH, 2 parts of glycerin, 0.6 parts of oleic acid amide, 0.6 parts of antioxidant 1010, 2-hydroxy-4-methoxydiphenyl Methanone 0.5 part, ADR4400 0.1 part.

[0060] S1. Prepare modified starch, the specific components are: 100 parts of starch with a water content of 8-10%, 0.6 parts of epoxidized soybean oil, 30 parts of glycerin, 5 parts of citric acid, 1 part of stearic acid, coupling agent KH550 2 5 parts, 5 parts of maleic anhydride, 0.5 parts of cumene peroxide.

[0061] All the other steps are the same as in Example 1.

Embodiment 3

[0063] A starch-modified PBAT / PLA biodegradable plastic film, in parts by weight, comprises the following components:

[0064] 50 parts of PBAT, 30 parts of PLA, 20 parts of modified starch, 5 parts of PHA, 1 part of ATBC, 0.5 parts of EBS, 0.6 parts of antioxidant 1010, 2-(2-hydroxy-5-methylphenyl)benzotri 0.5 part of azole, 0.2 part of ADR4468.

[0065] S1. Prepare modified starch, the specific components are: 100 parts of starch with a water content of 8-10%, 0.7 parts of epoxidized soybean oil, 15 parts of glycerin, 10 parts of citric acid, 1 part of stearic acid, and 1 part of coupling agent KH560 0.5 parts, coupling agent titanate coupling agent 201, 6 parts of maleic anhydride, 0.6 parts of cumene peroxide.

[0066] All the other steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transverse tensile strength | aaaaa | aaaaa |

| Longitudinal tensile strength | aaaaa | aaaaa |

| Heat seal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com