Polyphenylene sulfide composition and preparation method thereof

A technology of polyphenylene sulfide and polyphenylene sulfide resin, which is applied in the field of polymer materials, can solve the problems of insufficient mechanical strength and impact strength, insufficient weather resistance and stability of materials, poor performance of PPS composition, etc., and achieve excellent mechanical strength Performance and processability, improvement of yellowing phenomenon and thermal stability, effect of improving compatibility and interfacial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

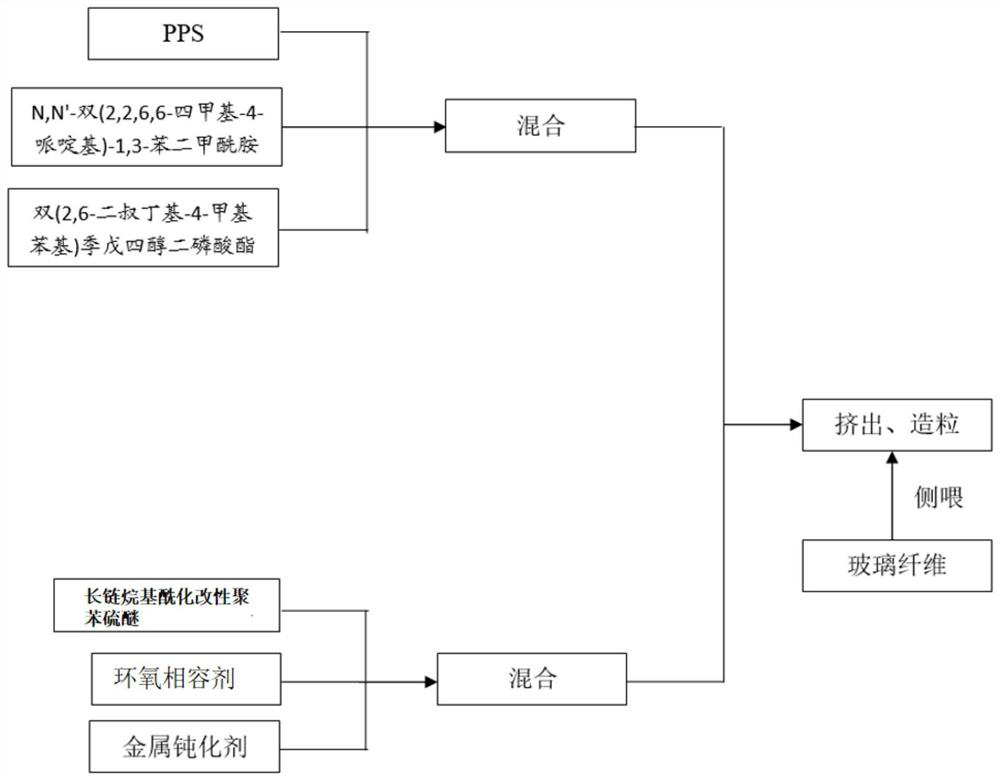

Method used

Image

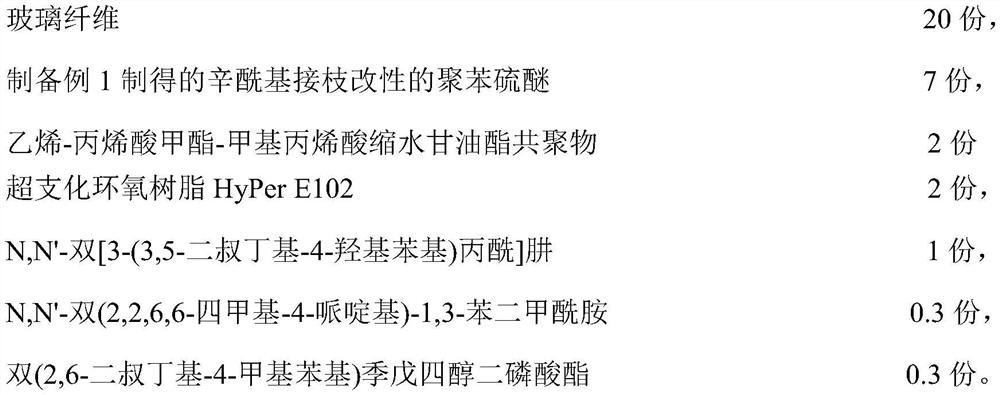

Examples

preparation example 1

[0036] 1kg of polyphenylene sulfide resin powder was placed in a stirred reactor, then 10 kg of anhydrous-treated dichloromethane was added, stirred for 10 hours to swell, and then the stirred reactor was evacuated and filled with nitrogen, repeated 6 times, At a reaction temperature of 37°C, add 0.75 kg of octanoyl chloride, and at the same time add 0.75 kg of catalyst aluminum trichloride. After reacting in this system for 4.5 hours, take out the reaction product and place it in 5% glacial hydrochloric acid for 6 hours. Finally, wash 4 times with 5% sodium hydroxide solution, then wash 4 times with distilled water and ethanol respectively, finally the product is extracted in a Soxhlet fat extractor with ethanol-distilled water for 24 hours, and after drying, octanoyl grafted Modified polyphenylene sulfide.

preparation example 2

[0038] Other conditions and operations were the same as those in Preparation Example 1, except that octanoyl chloride was replaced by hexanoyl chloride of equal mass to finally obtain hexanoyl graft-modified polyphenylene sulfide.

preparation example 3

[0040] Other conditions and operations were the same as those in Preparation Example 1, except that octanoyl chloride was replaced by decanoyl chloride of equal mass to finally obtain decanoyl graft-modified polyphenylene sulfide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com