Method for growing graphene film on surface of copper powder

A graphene film, surface growth technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the adverse effects of graphene film quality, hinder the excellent performance of graphene, graphene grain boundaries and defects many problems, to achieve the effect of improving quality, reducing grain boundaries and defects, and shortening growth time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a method for growing a graphene film on the surface of copper powder, which comprises the following steps in turn:

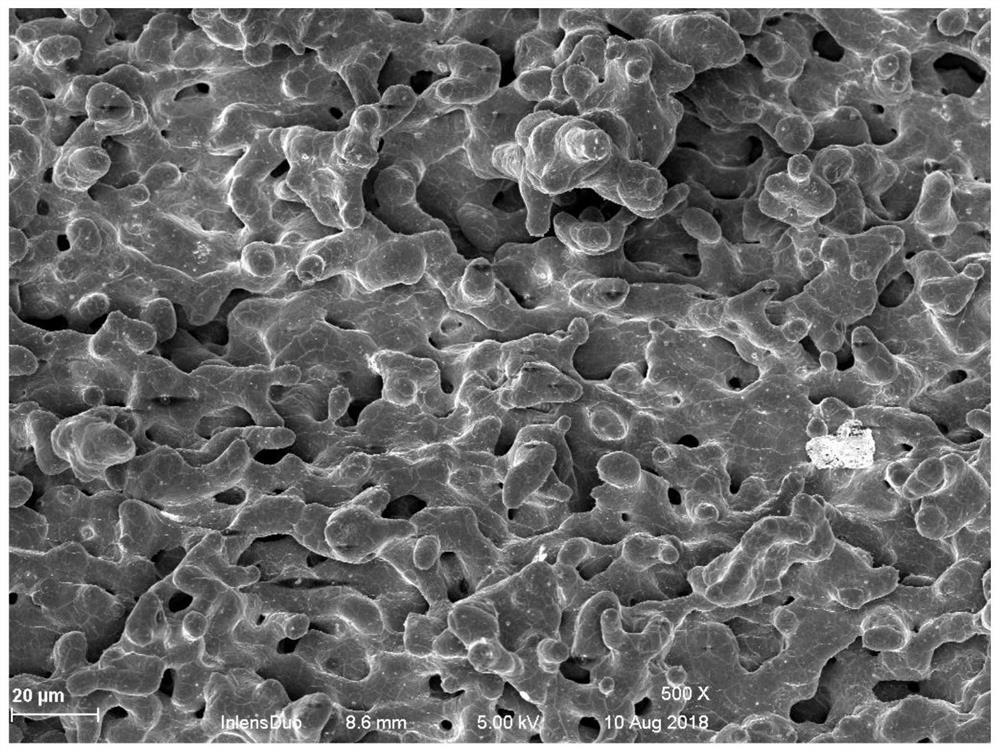

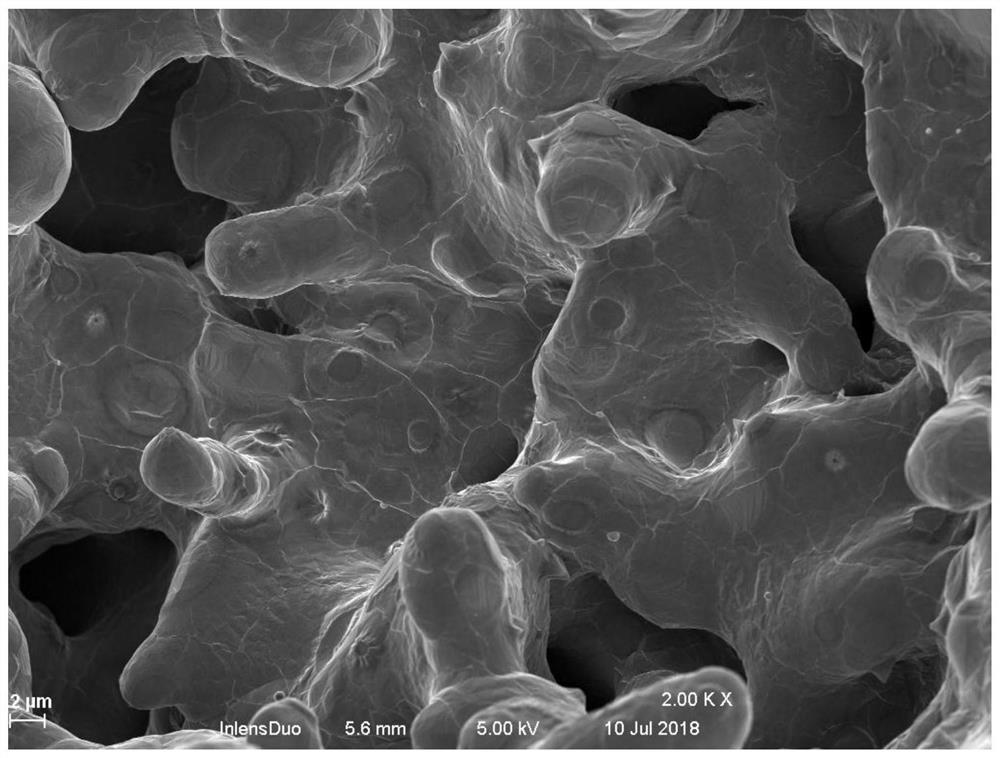

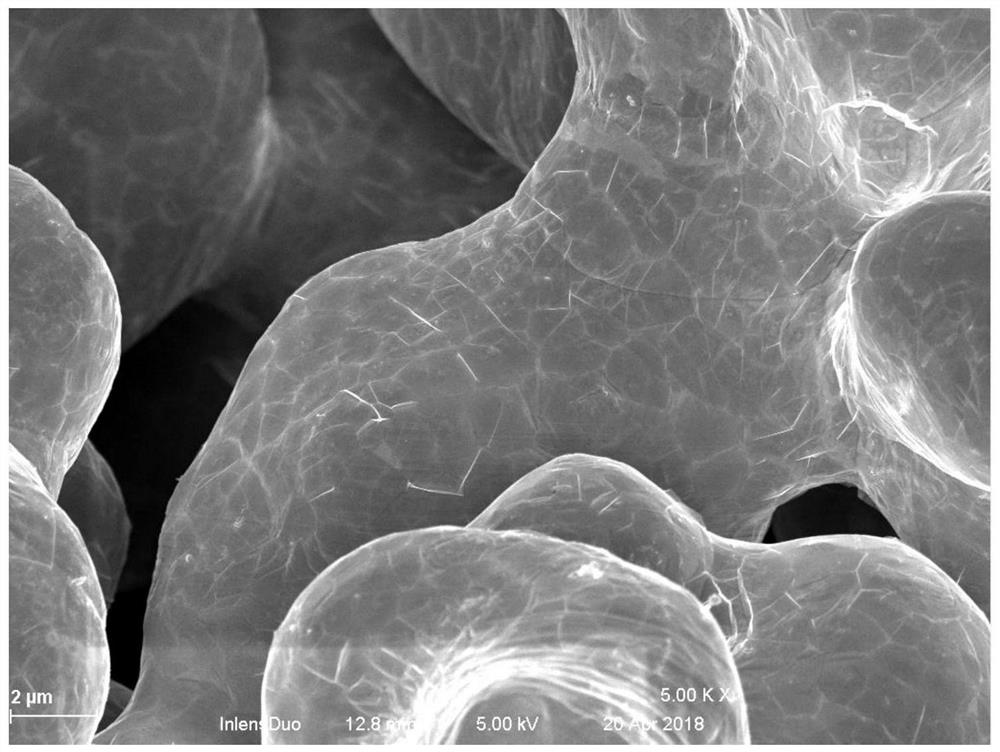

[0030] S1: Weigh 200g of 100-mesh copper powder, put it in a ceramic boat, and spread it evenly. The above-mentioned copper powder can be in any of spherical, dendritic or flake shapes; In the center of the constant temperature zone of the vapor deposition furnace, 300 sccm of argon gas is introduced, so that the copper powder is in an argon atmosphere, and the furnace temperature is raised from room temperature to 300 ° C in the argon atmosphere; the argon gas is closed and 1 sccm of oxygen is introduced Pre-oxidize the copper powder surface and keep it warm for 10 minutes.

[0031] In this embodiment, a pre-oxidation process of copper powder is inserted in the initial heating stage of the process, that is, when the temperature is raised to a lower temperature, the oxidation treatment of copper powder is carried out first,...

Embodiment 2

[0042] The present embodiment provides a method for growing a graphene film on the surface of copper powder, which comprises the following steps in turn:

[0043] S1: Put the mixed powder of copper powder and anti-sintering agent in a quartz boat and spread it evenly. The anti-sintering agent can be one of polyvinyl alcohol, sodium chloride, magnesium oxide, graphite powder and potassium carbonate or Various anti-sintering agents can be decomposed at high temperature to reduce the degree of sintering of copper powder. Anti-sintering agents that do not decompose at high temperatures can be removed in pure water, ethanol or acidic solution after sample preparation, without affecting the final sample. quality. This embodiment specifically uses the mixed powder of copper powder and anti-sintering agent sodium chloride, weighs 200g of 15000 mesh copper powder and 40g ultrafine sodium chloride powder, and uses a powder mixer to mix the copper powder and sodium chloride powder evenly...

Embodiment 3

[0050] The present embodiment provides a method for growing a graphene film on the surface of copper powder, which comprises the following steps in turn:

[0051] S1: Weigh 200g of 200-mesh copper powder, put it in a ceramic boat, and spread it evenly. The above-mentioned copper powder can be in any of spherical, dendritic or flake shapes; In the center of the constant temperature zone of the vapor deposition furnace, 100 sccm of nitrogen gas is introduced, so that the copper powder is in an argon atmosphere, and the furnace temperature is raised from room temperature to 250 °C in the nitrogen atmosphere; the nitrogen gas is closed and 2 sccm of oxygen is introduced to the copper powder. The surface is oxidized and kept warm for 10 minutes.

[0052] S2: Turn off the oxygen after 10 minutes of heat preservation, and resume the introduction of 100sccm nitrogen again. In the argon atmosphere, the furnace temperature continues to rise to 1020°C, and then a mixed gas of methane, hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com