Preparation method of efficient atomic-scale tungsten dispersion catalyst, product and application

A catalyst and atomic technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of limited improvement of catalyst catalytic effect, difficulty in realizing catalytic activity, complicated process, etc., and achieve the effect of low cost, easy operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Co of the present invention 9 S 8 The preparation method belongs to the conventional preparation method of the prior art, which can refer to the literature (Adv. Energy Mater. 2020, 10, 1903137), and will not be described in detail herein.

[0031] The instrument used in the embodiment has:

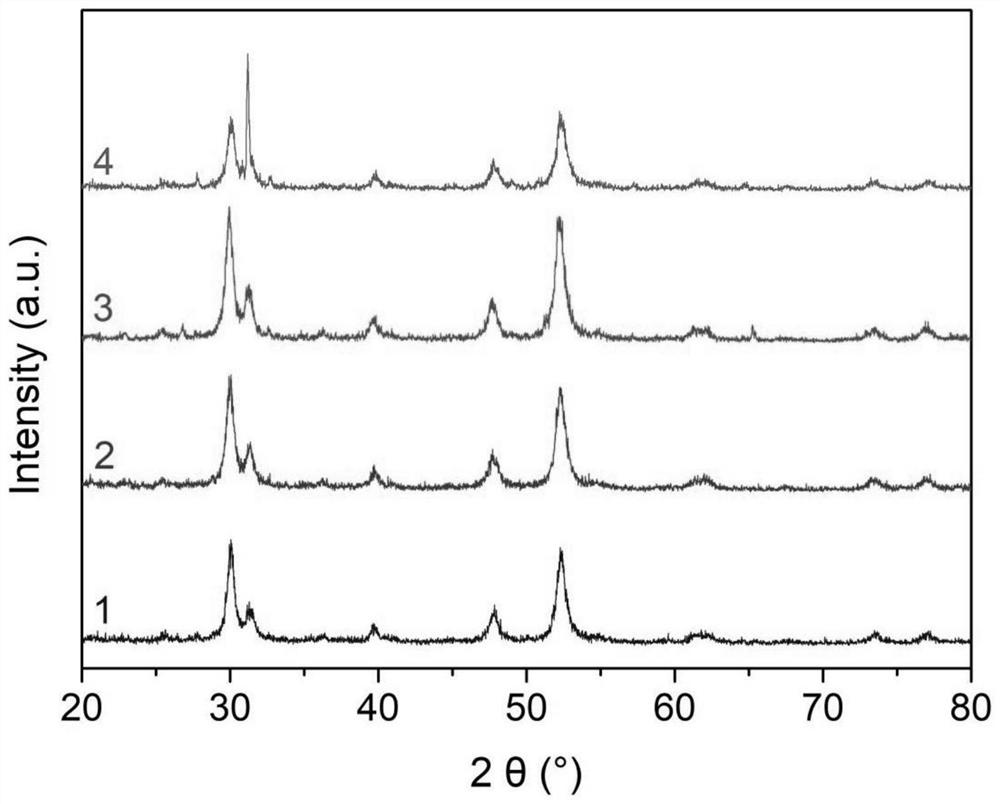

[0032] Powder X-ray diffractometer (model is: rational science RigakuD / Max-2000 rotating target, wherein copper K α radiation diffractometer In the study, the continuous scanning mode was used for phase identification, the scanning voltage for qualitative phase analysis was set to 40kV, the current was set to 100mA, and the scanning range was 5-80°); scanning electron microscope (model: HitachiS-4800); Transmission electron microscope (model: JEM-2100); high-resolution transmission electron microscope (model: JEM-2100F); spherical aberration-corrected transmission electron microscope (model: FEI Titan Themis G2); synchrotron radiation extended edge X-ray absorption fine structu...

Embodiment 1

[0035] (1) 6 mg of ammonium metatungstate ((NH 4 ) 6 W 7 o 24 4H 2 O) be dissolved in a beaker containing 20mL octylamine solution, then, add 1.0g of Co 9 S 8 , stirred at room temperature for 15 minutes to obtain a precursor;

[0036] (2) Place the precursor in an autoclave, and put it into an electric blast drying oven at a temperature of 200 °C for 24 h at a constant temperature to obtain a two-dimensional W-Co 9 S 8 nanosheet material;

[0037] (3) Take out the two-dimensional W-Co 9 S 8 The nanosheet material was naturally cooled to room temperature, the black solid precipitate was collected by centrifugation, and then washed 3 times with deionized water and ethanol, and the washed sample was kept at 70 °C for 24 h for drying, and the obtained product was Co 9 S 8 A catalyst loaded with 0.48 wt% atomically dispersed W, denoted as W-Co 9 S 8 .

Embodiment 2

[0039] With embodiment 1, the difference is that the ammonium metatungstate quality is 12mg in the step (1). According to the same preparation method as in Example 1, 0.95wt% tungsten-loaded W-Co 9 S 8 nanocrystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com