Positive electrode composite material for lithium primary battery and preparation method thereof

A lithium primary battery and composite material technology, applied in the direction of battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of heat generation and high rate performance, and achieve complex structure, uniform appearance, and large industrialization potential Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Dissolve bismuth alcohol salt in isopropanol solvent to prepare 0.5mol / L bismuth alkoxide solution;

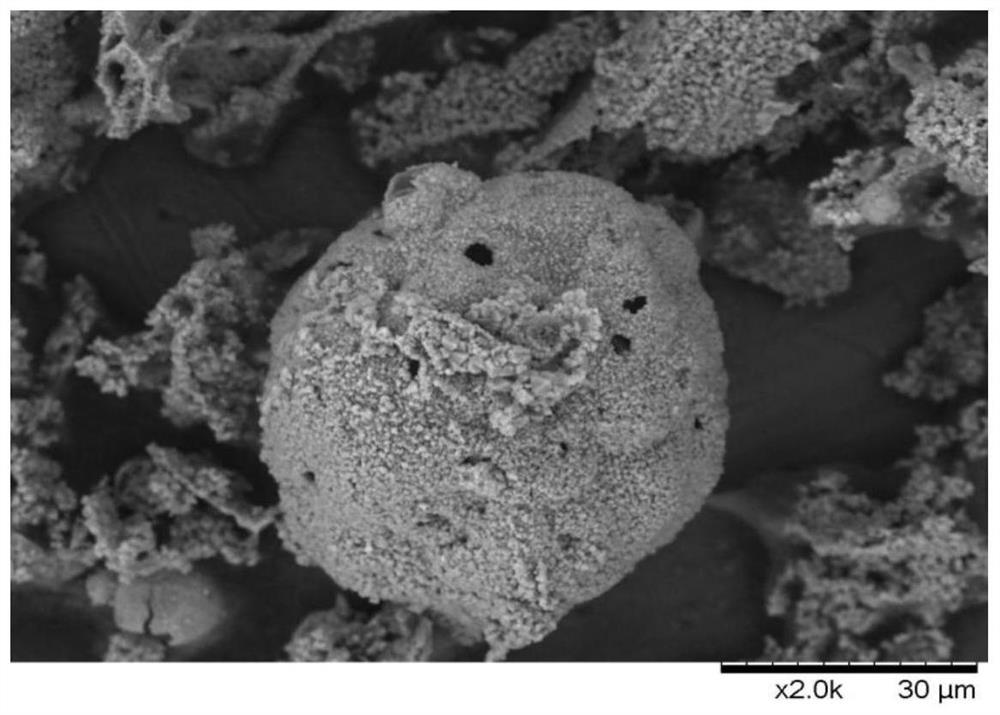

[0034]2. Using HF as the carrier gas, atomize and spray the above bismuth alkoxide solution into the spray pyrolysis furnace at 800°C. Among them, the flow rate of HF is controlled at about 50ml / s, and the bismuth alkoxide solution is controlled at about 20ml / s, and the prepared porous fluoride spherical particles with uniform appearance are ready for use;

[0035] 3. Mix the porous fluoride prepared in step 2 with elemental sulfur at a mass ratio of 1:4, put it into a closed steel container, and then place it in a sintering furnace with an argon atmosphere, and treat it at 150°C for 6h, and naturally After cooling, the product is taken out to obtain BiF 3 @CF x @S Spherical cathode composite.

Embodiment 2

[0037] 1. BiF 3 @CF x @S The positive electrode composite material, Ketjen black, and binder PVDF are mixed in a ratio of 8:1:1, and the slurry is prepared in NMP solvent; 2. Use a scraper to scrape the positive electrode slurry on the aluminum foil, and put it in a drum at 80°C Dry in an air oven for later use.

[0038] 3. Cut the dried positive electrode into The disc, and assemble the button battery with the lithium sheet to evaluate the material performance;

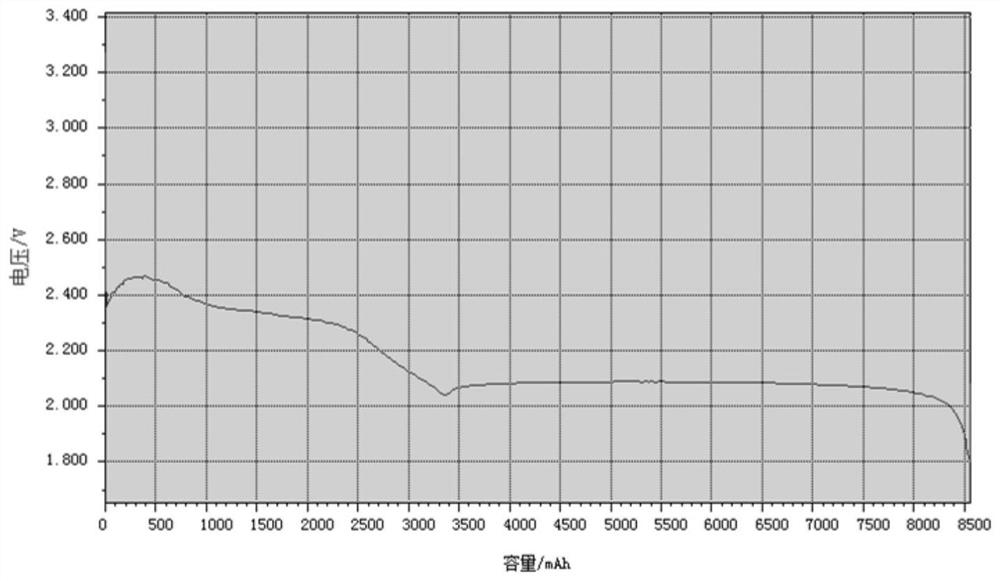

[0039] 4. The button half-cell is discharged at a rate of 0.05C, and the gram capacity of the positive electrode composite material reaches 1208mAh / g.

Embodiment 3

[0041] 1. Dissolve isopropanol copper salt in isopropanol solvent to prepare 0.5mol / L copper alkoxide solution;

[0042] 2. With HF as the carrier gas, atomize and spray the above copper alkoxide solution into the spray pyrolysis furnace at 800°C. Among them, the flow rate of HF is controlled at about 50ml / s, and the copper alcohol solution is controlled at about 20ml / s, and the prepared porous fluoride spherical particles with uniform appearance are ready for use;

[0043] 3. Mix the porous fluoride prepared in step 2 with elemental sulfur at a mass ratio of 1:4, put it into a closed steel container, and then place it in a sintering furnace with an argon atmosphere, and treat it at 150°C for 6h, and naturally After cooling, the product is taken out to obtain CuF 2 @CF x @S Spherical cathode composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com