Scale inhibitor for reverse osmosis membrane as well as preparation method and application of scale inhibitor

A reverse osmosis membrane and antiscalant technology, which is applied in the field of reverse osmosis membrane antiscalant and its preparation, can solve problems such as the reduction of water production rate and water quality, restrictions on the application of reverse osmosis technology, and the impact on equipment use efficiency. The effect of improving silicon resistance performance, excellent scale inhibition level, and good calcium-silicon tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a preparation method of the reverse osmosis membrane antiscalant described in the technical solution, comprising the following steps:

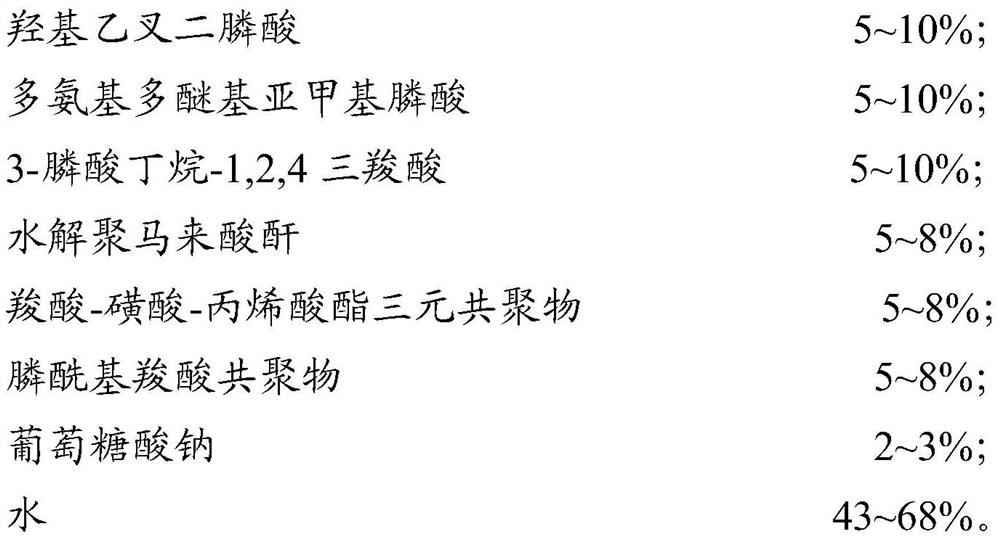

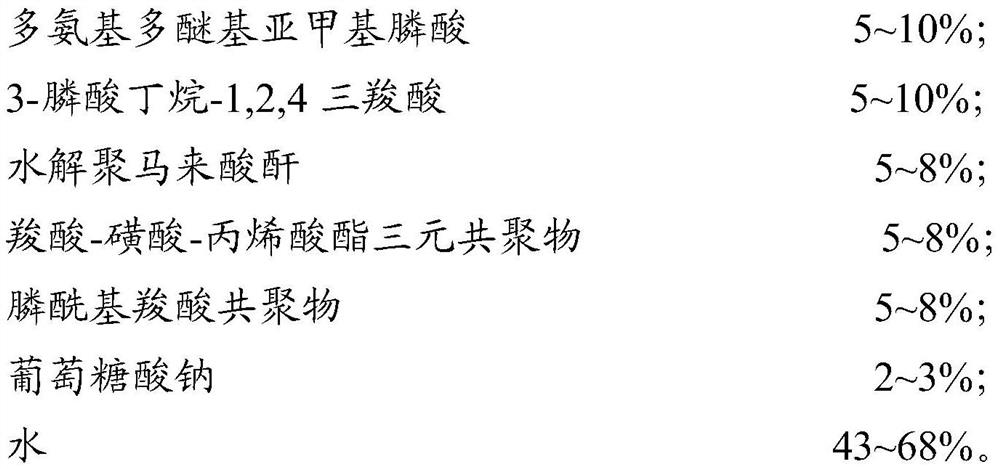

[0032] Hydroxyethylidene diphosphonic acid, polyamino polyether group methylene phosphonic acid, 3-phosphonic acid butane-1,2,4 tricarboxylic acid, hydrolyzed polymaleic anhydride, carboxylic acid-sulfonic acid-acrylate tri A multipolymer, a phosphonocarboxylic acid copolymer, sodium gluconate and water are mixed to obtain a reverse osmosis membrane scale inhibitor.

[0033] In the preparation method provided by the present invention, the above-mentioned components are uniformly mixed in proportion to obtain the antiscalant for reverse osmosis membrane provided by the present invention. Wherein, the mixing temperature is preferably normal temperature (25°C); the mixing pressure is preferably normal pressure (one atmosphere); the mixing speed is preferably 60-150r / min; the mixing time is preferably 2h ...

Embodiment 1

[0041] Hydroxyethylidene diphosphonic acid (HEDP) 10g, polyamino polyether group methylene phosphonic acid (PAPEMP) 10g, 2-phosphonic acid butane-1,2,4 tricarboxylic acid (PBTCA) 10g, hydrolyzed polymass Toric anhydride (HPMA) 5g, carboxylic acid-sulfonic acid-acrylate terpolymer (AA-AMPS-HPA) 5g, phosphonocarboxylic acid copolymer (POCA) 5g, sodium gluconate 3g and water 52g, at room temperature Stir (60-150r / min) under high pressure and mix for 2 hours to obtain a uniform transparent reddish-brown reverse osmosis membrane scale inhibitor.

Embodiment 2

[0043] Hydroxyethylidene diphosphonic acid (HEDP) 5g, polyamino polyether group methylene phosphonic acid (PAPEMP) 5g, 2-phosphonic acid butane-1,2,4 tricarboxylic acid (PBTCA) 5g, hydrolyzed polymass Toric anhydride (HPMA) 5g, carboxylic acid-sulfonic acid-acrylate terpolymer (AA-AMPS-HPA) 5g, phosphonocarboxylic acid copolymer (POCA) 5g, sodium gluconate 2g and water 68g, at room temperature Stir (60-150r / min) under high pressure and mix for 2 hours to obtain a uniform transparent reddish-brown reverse osmosis membrane scale inhibitor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com