Preparation method of graphene/carbon nanotube composite array material

A carbon nanotube array and graphene sheet technology, applied in the direction of carbon nanotubes, graphene, nanocarbon, etc., can solve the problem that graphene is difficult to separate carbon nanotubes evenly, achieve excellent ion exchange performance, and increase specific surface area , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1, preparing a graphene sheet / carbon nanotube array.

[0022] The first step is to prepare the catalyst.

[0023] Use vermiculite with a particle size of 4-8 mm and mix it with distilled water to form a suspension. Subsequently, ferric nitrate (Fe(NO 3 ) 3 9H 2 O), ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) make homogeneous solution, after two kinds of solutions are fully mixed, slowly pour into vermiculite suspension and stir simultaneously, the mixture that obtains keeps 12 hours at 90 ℃, carries out ion exchange between vermiculite layer in this process, Ca 2+ , Mg 2+ , K + and Na + exchanged for Fe 3+ . Finally, it was filtered, dried, and calcined at 300 °C for 2 hours to obtain a layered Fe / Mo / vermiculite catalyst.

[0024] The second step is to prepare graphene sheets / carbon nanotubes.

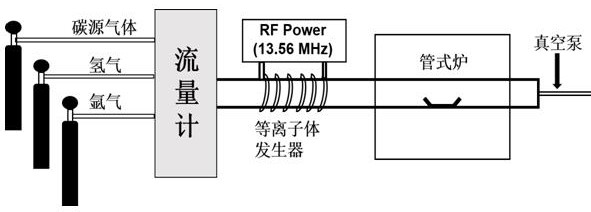

[0025] Using experimental equipment such as figure 1 As shown, the prepared vermiculite was evenly spread on the bottom of the ceramic boat and plac...

Embodiment 2

[0027] The first step is to prepare the catalyst.

[0028] Use vermiculite with a particle size of 4-8 mm and mix it with distilled water to form a suspension. Subsequently, ferric nitrate (Fe(NO 3 ) 3 9H 2 O), ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) make homogeneous solution, after two kinds of solutions are fully mixed, slowly pour into vermiculite suspension and stir simultaneously, the mixture that obtains keeps 12 hours at 90 ℃, carries out ion exchange between vermiculite layer in this process, Ca 2+ , Mg 2+ , K + and Na + exchanged for Fe 3+ . Finally, it was filtered, dried, and calcined at 300 °C for 2 hours to obtain a layered Fe / Mo / vermiculite catalyst.

[0029] The second step is to prepare graphene sheets / carbon nanotubes.

[0030] Using experimental equipment such as figure 1 As shown, the prepared vermiculite was evenly spread on the bottom of the ceramic boat and placed in the center of the heating area of the quartz tube. Before the ...

Embodiment 3

[0032] The first step is to prepare the catalyst.

[0033] Use vermiculite with a particle size of 4-8 mm and mix it with distilled water to form a suspension. Subsequently, ferric nitrate (Fe(NO 3 ) 3 9H 2 O), ammonium molybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) make homogeneous solution, after two kinds of solutions are fully mixed, slowly pour into vermiculite suspension and stir simultaneously, the mixture that obtains keeps 12 hours at 90 ℃, carries out ion exchange between vermiculite layer in this process, Ca 2+ , Mg 2+ , K + and Na + exchanged for Fe 3+ . Finally, it was filtered, dried, and calcined at 300 °C for 2 hours to obtain a layered Fe / Mo / vermiculite catalyst.

[0034] The second step is to prepare graphene sheets / carbon nanotubes.

[0035] Using experimental equipment such as figure 1 As shown, the prepared vermiculite was evenly spread on the bottom of the ceramic boat and placed in the center of the heating area of the quartz tube. Before the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com