Jet high-speed steel without annular segregation and with secondary hardening function and manufacturing method for jet high-speed steel

A technology of secondary hardening and manufacturing method, applied in metal processing equipment and other directions, can solve problems such as hindering the application and development of spray-deposited high-speed steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

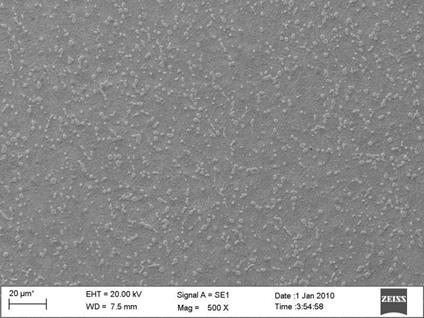

Image

Examples

Embodiment 1

[0043] This embodiment provides a sprayed high-speed steel without annular segregation and secondary hardening, and its components include: carbon: 1.70%, molybdenum: 3.00%, chromium: 6.00%, vanadium: 8.00%, niobium: 2.50%, silicon: 0.20~0.35%, manganese: 0.50~0.90%, sulfur: ≤0.040%, phosphorus: ≤0.040%, oxygen: 0.005~0.015%, nitrogen: 0.030~0.040%, the remainder is iron and unavoidable Impurities, the main metal element components except iron are added in the form of alloy, and the alloy form is one or more of ferromolybdenum, ferrochrome, ferrovanadium and ferroniobium.

[0044] The process steps are as follows:

[0045] Step 1: The ingredients are configured according to the above components for smelting raw materials;

[0046] Step 2: Intermediate frequency induction melting:

[0047] (1) Melting by induction heating in a 4-ton intermediate frequency furnace, the inclination angle of the crucible is -15°~105°, adding industrial pure iron and ferromolybdenum in sequence, ...

Embodiment 2

[0064] This embodiment provides a sprayed high-speed steel without annular segregation and secondary hardening and its manufacturing method, its components include: carbon: 1.80%, tungsten: 6.00%, molybdenum: 5.00%, chromium: 4.00% %, vanadium: 6.00%, niobium: 2.00%, silicon: 0.20~0.35%, manganese: 0.50~0.90%, sulfur: ≤0.040%, phosphorus: ≤0.040%, oxygen: 0.005~0.015%, nitrogen: 0.030~0.040 %, the remainder is iron and unavoidable impurities. The main metal element components are all added in the form of alloy except iron. one or more species.

[0065] The process steps are as follows:

[0066] Step 1: The ingredients are configured according to the above components for smelting raw materials;

[0067] Step 2: Intermediate frequency induction melting:

[0068] (1) Induction heating and melting in a 4-ton intermediate frequency furnace, the inclination angle of the crucible is -15°~105°, adding industrial pure iron, tungsten iron, and molybdenum iron in sequence, until the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com