Rapid preparation method and application of efficient oil-water separation membrane

An oil-water separation membrane and high-efficiency technology, which is applied in the field of rapid preparation of high-efficiency oil-water separation membranes, can solve the problems of long membrane preparation time and large-scale industrial production problems, and achieves a time-saving and labor-saving, good mechanical performance and rapid membrane preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A rapid preparation method of a high-efficiency oil-water separation membrane, comprising the steps of:

[0028] (1) Wash the 400-mesh phosphorus copper mesh with acetone, ethanol, and ultrapure water for 20 minutes under ultrasonic conditions to remove surface oil, and dry it at 60°C for later use;

[0029] (2) Weigh 0.8g of polyvinylidene fluoride and dissolve it in 10mL of N,N-dimethylformamide, and magnetically stir for 8 hours at room temperature to obtain a homogeneously dissolved polyvinylidene fluoride modified solution;

[0030] (3) Cut the phosphor copper omentum into a size of 5cm*5cm, squeeze out 1.5ml of the modified solution from the needle tube to one side of the omentum, scrape it evenly with a scraper, turn the omentum over and repeat the coating once (no need for another modified solution), and dried at 50°C to obtain the oil-water separation omentum.

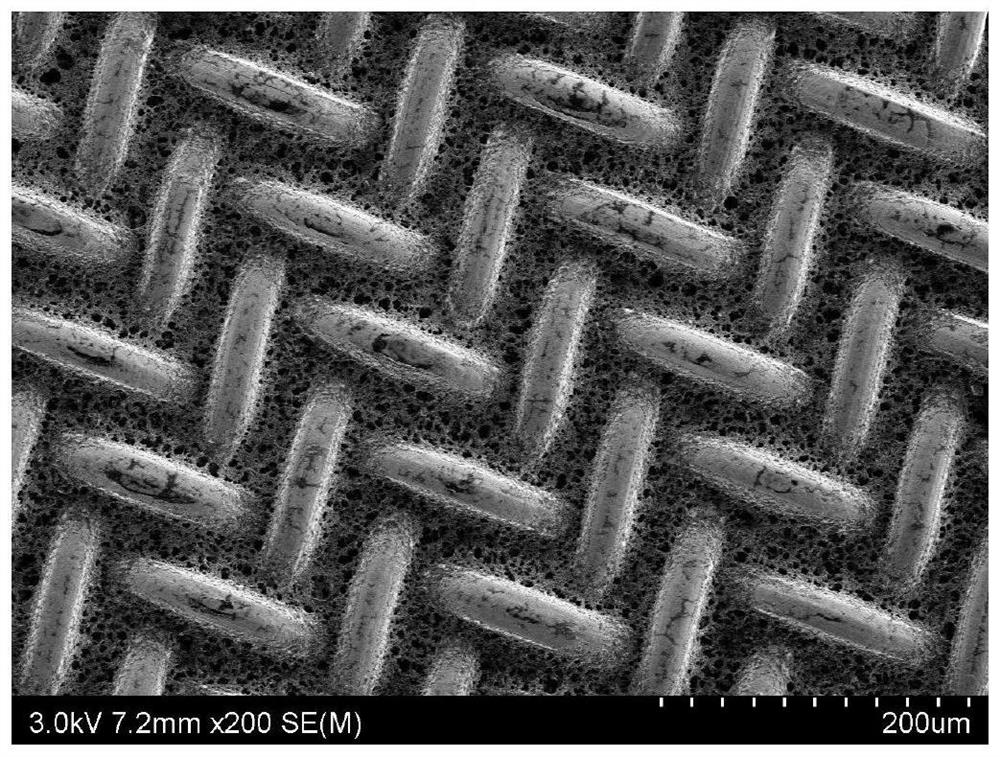

[0031] The surface topography scanning electron microscope photo of the oil-water separation omentu...

Embodiment 2

[0034] A rapid preparation method of a high-efficiency oil-water separation membrane, comprising the steps of:

[0035] (1) Wash the 500-mesh stainless steel mesh with acetone, ethanol, and ultrapure water for 20 minutes under ultrasonic conditions to remove the oil on the surface, and dry it at 60°C for later use;

[0036] (2) Weigh 0.6g of polyvinylidene fluoride and 0.32g of polyvinylidene fluoride copolymerized hexafluoropropylene and dissolve them in a mixture of 6mL N,N-dimethylformamide and 4mL of acetone, stir magnetically at room temperature for 8h, and obtain a uniform solution Polyvinylidene fluoride and polyvinylidene fluoride copolymer hexafluoropropylene modified solution;

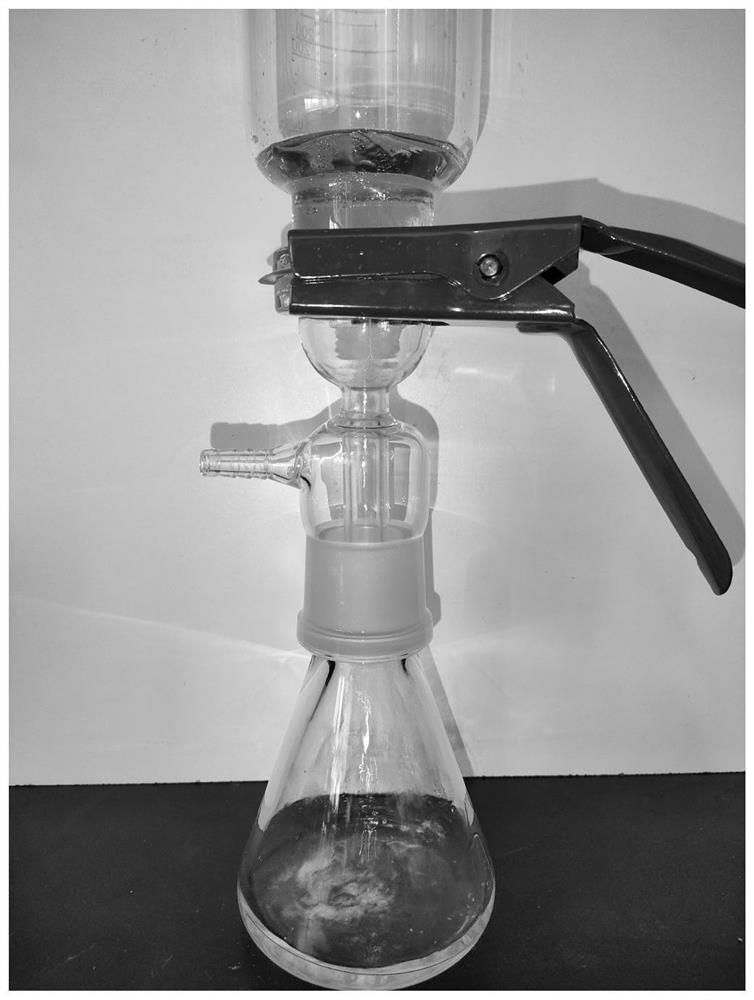

[0037] (3) Cut the stainless steel omentum into a size of 5cm*5cm, squeeze 1ml of the modified solution from the needle tube to one side of the omentum, scrape it evenly with a scraper, turn the omentum over and repeat it once (no additional modification is required) solution), and the oil-w...

Embodiment 3

[0041] A rapid preparation method of a high-efficiency oil-water separation membrane, comprising the steps of:

[0042] (1) Wash the 450-mesh nylon mesh with acetone, ethanol, and ultrapure water for 20 minutes under ultrasonic conditions to remove oil stains on the surface, and dry it at 60°C for later use;

[0043] (2) Weigh 0.72g of polyvinylidene fluoride copolymerized hexafluoropropylene and dissolve it in 10mL of N, N-dimethylformamide, stir magnetically at room temperature for 8 hours to obtain a homogeneously dissolved polyvinylidene fluoride copolymerized hexafluoropropylene modified solution ;

[0044] (3) Cut the nylon omentum into a size of 5cm*5cm, take 1.2ml of modified solution and extrude it onto one side of the omentum, apply it evenly with a brush, turn the omentum over and repeat it once (no additional modification is required) solution), and the oil-water separation omentum was obtained after drying at 50°C.

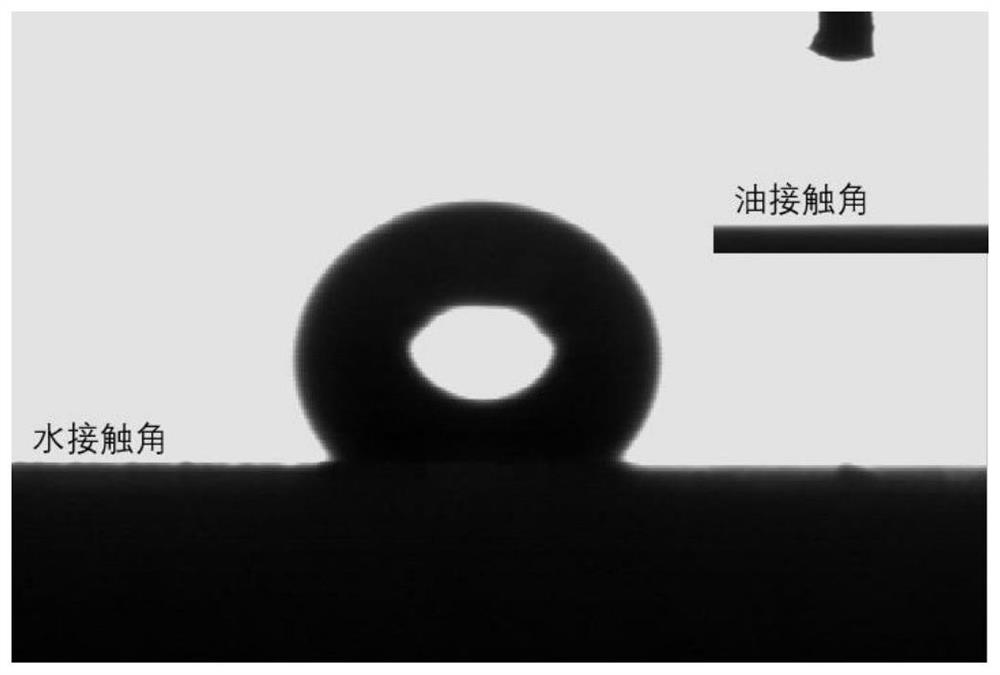

[0045] The contact angle of the oil-water sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com