Preparation method of fiber diaphragm and pole piece

A fiber membrane and negative electrode material technology, applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve problems such as hole plugging, wire breakage, and technical difficulty, and improve energy density and safety. , good adaptability, the effect of reducing internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A kind of fiber diaphragm of ternary 622 positive pole, its raw material composition is specifically as follows:

[0051] Dispersed polytetrafluoroethylene powder (particle size between 300um-450um, molecular weight greater than 1 million) 15g, conductive carbon black SP 10g, super conductive carbon black EC 10g and positive electrode 622 type nickel-cobalt-manganese ternary battery material 965g;

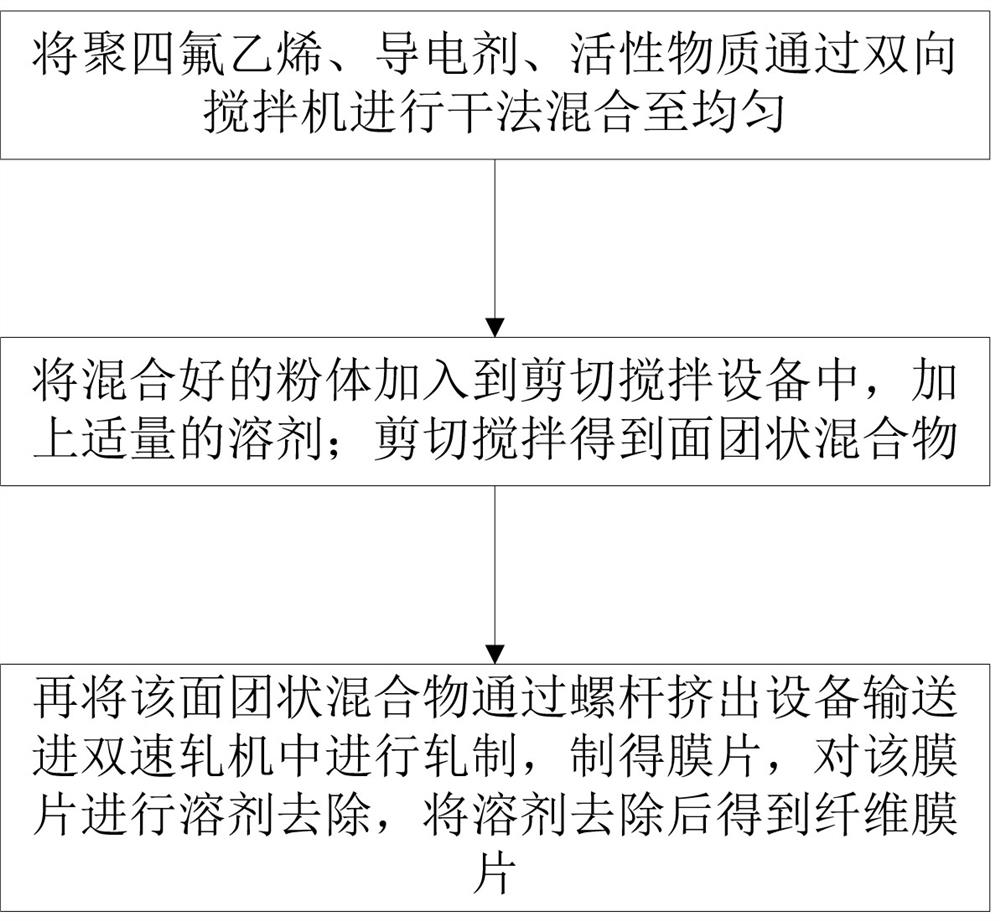

[0052] Its preparation method steps are as follows:

[0053] Step 1. Put dispersed polytetrafluoroethylene powder, conductive carbon black SP, super conductive carbon black EC and 622-type nickel-cobalt-manganese ternary battery materials in a two-way mixer and mix them to obtain a mixture in which the raw materials are uniformly dispersed with each other ; In order to prevent material segregation, the stirring speed of the present embodiment is set to 35r / min, and the stirring time is 180min;

[0054] Step 2. Put the mixture obtained in step 1 into a kneading machine, add ...

Embodiment 2

[0058] A fiber membrane of negative electrode mesocarbon microspheres, the raw material composition is as follows:

[0059] Dispersed polytetrafluoroethylene powder (particle size between 300um-450um, molecular weight greater than 1 million) 10g, conductive graphite KS-6 30g, carbon nanotube CNTs 10g and negative mesophase carbon microsphere battery material 950g;

[0060] Its specific preparation method steps are as follows:

[0061] Step 1. Put the dispersed polytetrafluoroethylene powder, conductive graphite KS-6, carbon nanotubes CNTs and negative electrode mesophase carbon microsphere battery materials in a two-way mixer and mix them to obtain a mixture in which the raw materials are uniformly dispersed with each other; In order to prevent material segregation, the stirring speed in this embodiment is set to 45r / min, and the stirring time is 240min.

[0062] Step 2. Put the mixture obtained in Step 1 into a kneading machine, add 350g of ethylene glycol as a solvent to th...

Embodiment 3

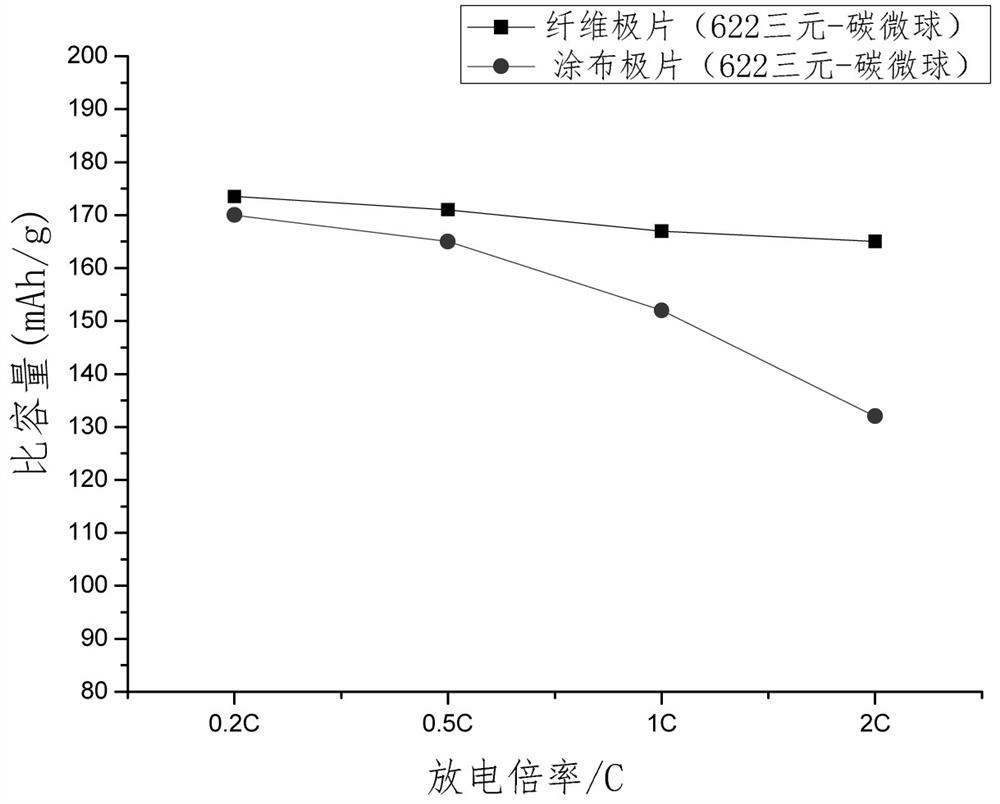

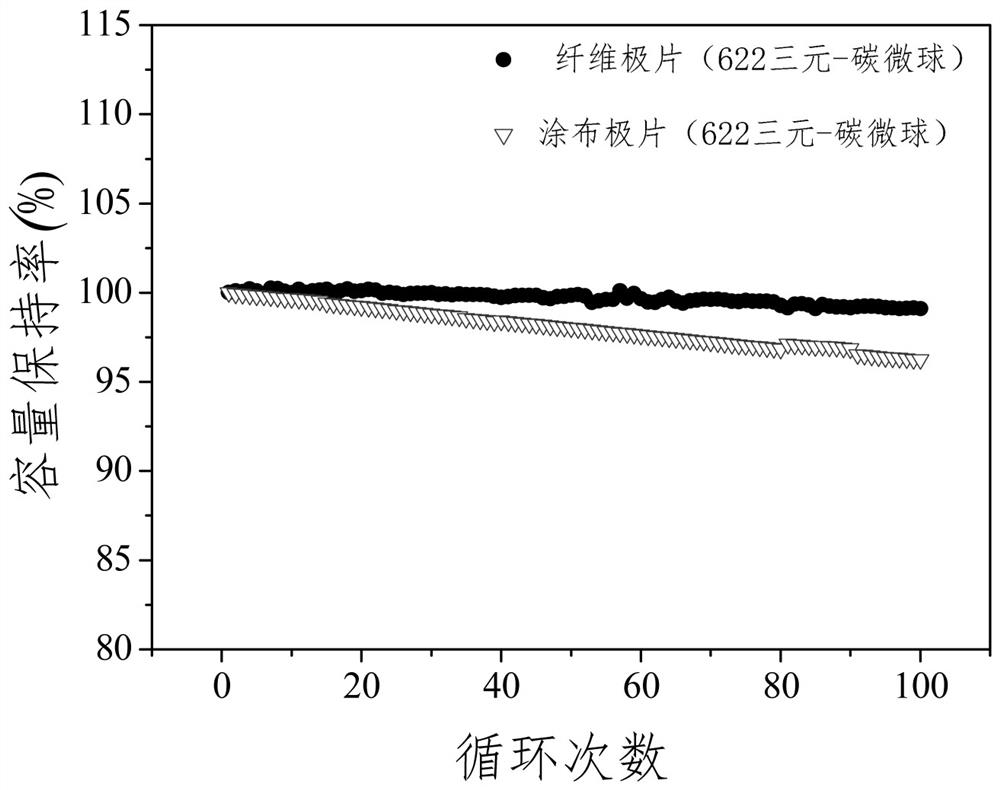

[0066] Utilize the positive and negative electrode fiber diaphragms that embodiment 1 and 2 prepare to prepare pole piece, concrete steps are as follows:

[0067] First, the conductive slurry is coated on both sides of the current collector, and then the fiber membrane is applied to both sides of the current collector and pressed by a rolling mill, dried, and then rolled to obtain a pole with a fiber structure. piece;

[0068] The compacted density of the fiber membrane applied on both sides of the current collector is 3.4g / cm2 at the positive pole. 3 ; Negative electrode 1.5g / cm 3 ; The thickness of the fiber membrane applied on both sides of the current collector, the positive pole on one side is 140um, and the density on one side is 47.6mg / cm 2 ;Single-side negative electrode is 160um, single-side surface density is 24mg / cm 2 ; Then made into a pouch battery for electrical performance testing.

[0069] In addition, the wet coating process was used to produce pole pieces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com