Niobium alloy surface high-temperature-resistant high-oxygen-barrier heat-insulating coating and preparation method thereof

A heat-insulating coating and high-temperature-resistant technology, applied in metal material coating process, coating, superimposed layer plating, etc. The effect of reducing surface temperature, improving bonding strength and avoiding oxidation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

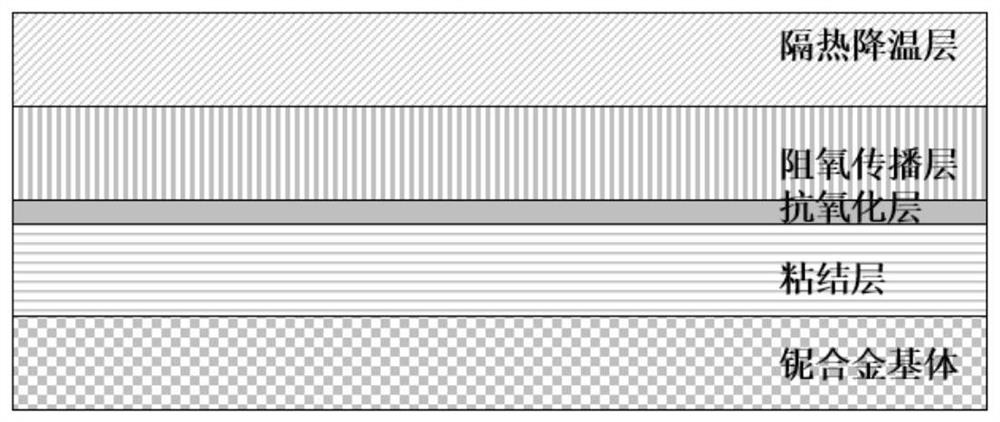

[0042] In order to further expand the application range of niobium-based alloy materials, increase its limit working temperature, and solve the problems of metal niobium oxidation failure in high-temperature aerobic environment, combined with figure 1 As shown, the present invention provides a method for preparing a high-temperature-resistant, high-resistance, oxygen-resistant heat-insulating coating on the surface of a niobium alloy. In sequence, an adhesive layer, an anti-oxidation layer, an oxygen-resistant propagation layer, and an insulating layer are prepared on the surface of a niobium-based alloy. The thermal cooling layer comprises the steps of:

[0043] (1) Using metal tantalum to form a bonding layer on the surface of the niobium-based alloy;

[0044] (2) The bonding layer is placed in the air, and the metal tantalum is oxidized, so that a tantalum oxide anti-oxidation layer is formed on the surface of the bonding layer;

[0045] (3) Prepare and form an oxygen barr...

Embodiment 1

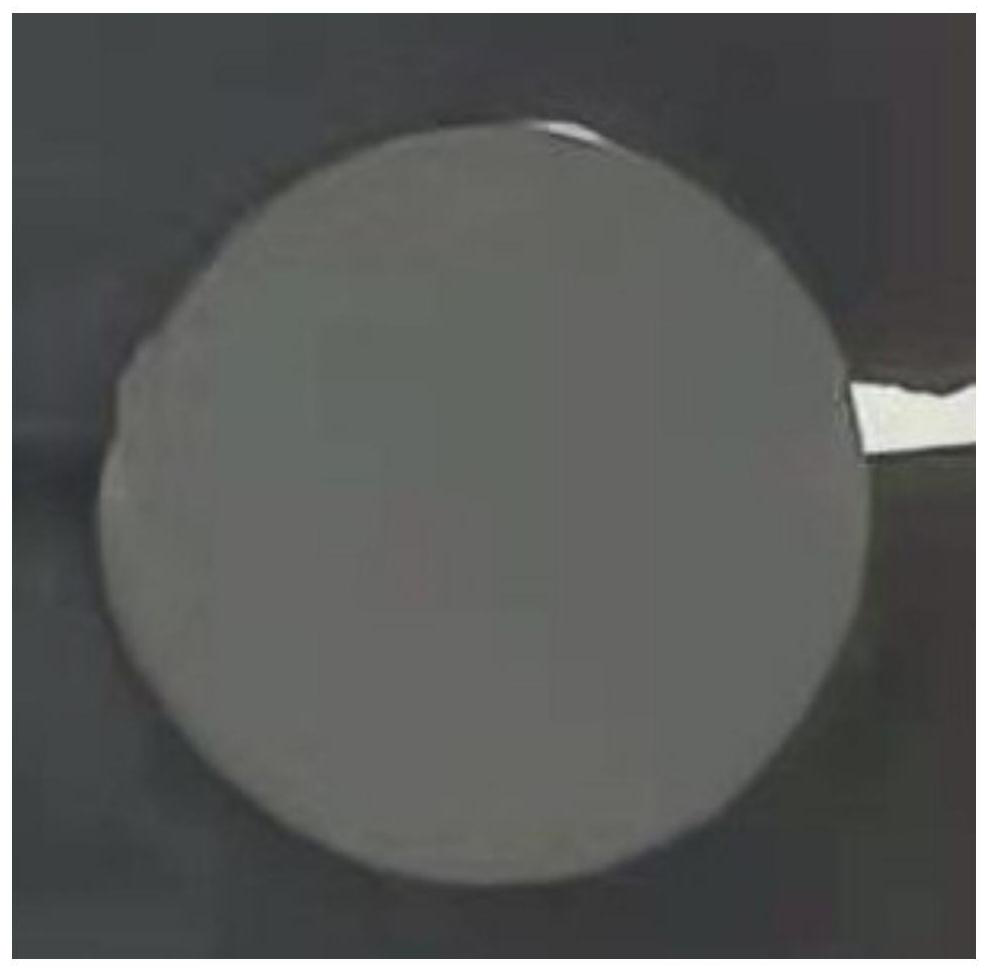

[0065] In this example, the GH3044 niobium alloy material is used as the substrate, and a coating composed of "adhesive layer + oxidation resistance layer + oxygen barrier transmission layer + heat insulation and cooling layer" is prepared on the surface of the niobium alloy substrate. The steps are as follows:

[0066] (1) Prepare a metal tantalum coating with a thickness of 80 microns on the surface of the niobium-based alloy by cold spraying, and the particle size of the metal tantalum spherical powder used is 30 to 70 microns; during the cold spraying process, compressed nitrogen is used as the working gas. The spraying pressure is 0.76MPa, the spraying distance is 30mm, the spraying temperature is 1000°C, the powder feeding rate is 40g / min, the coating deposition rate is 20 microns per minute, and the spraying time is 4 minutes.

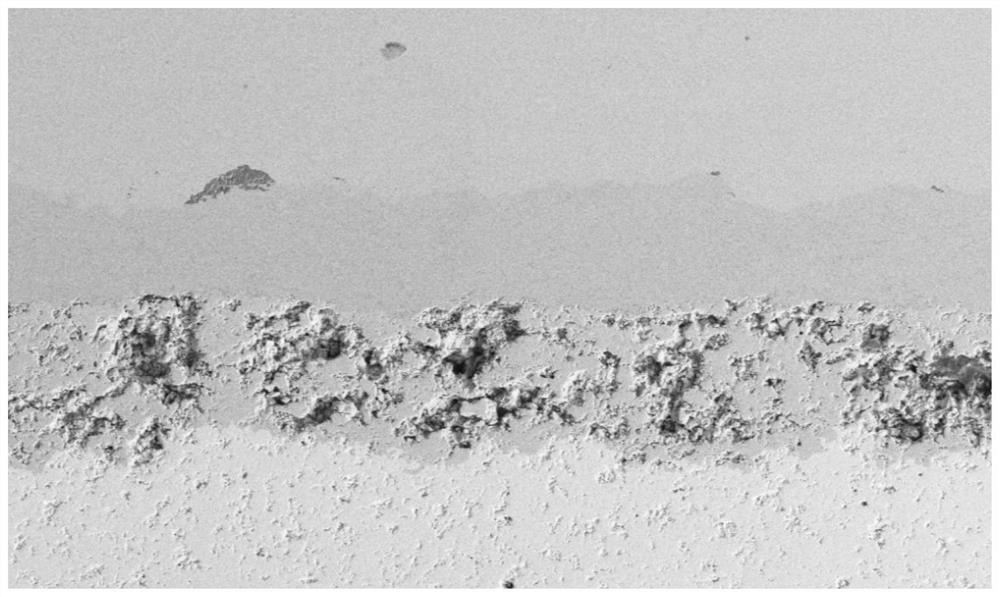

[0067] (2) After the sprayed metal tantalum bonding layer is placed in the air for more than one hour, the metal tantalum is oxidized, and a den...

Embodiment 2

[0075] In this example, the GH3044 niobium alloy material is used as the substrate, and a coating consisting of "adhesive layer + oxidation resistance layer + oxygen barrier transmission layer + heat insulation and cooling layer" is prepared on the surface of the niobium alloy substrate. The steps are as follows:

[0076] (1) Prepare a metal tantalum coating with a thickness of 60 microns on the surface of the niobium-based alloy by cold spraying, and the particle size of the metal tantalum spherical powder used is 30 to 70 microns; during the cold spraying process, compressed nitrogen is used as the working gas. The spraying pressure is 0.76MPa, the spraying distance is 30mm, the spraying temperature is 1000°C, the powder feeding rate is 40g / min, the coating deposition rate is 20 microns per minute, and the spraying time is 3 minutes.

[0077] (2) After the sprayed metal tantalum bonding layer is placed in the air for more than one hour, the metal tantalum is oxidized, and a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com