Washable antibacterial fabric and preparation method thereof

An antibacterial fabric and washable technology, which is applied in the fields of plant fiber, textile, papermaking, biochemical fiber treatment, etc., can solve the problems of complicated process, low adsorption efficiency, poor fastness, etc., and achieves cheap and easy-to-obtain raw materials and simple preparation process , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

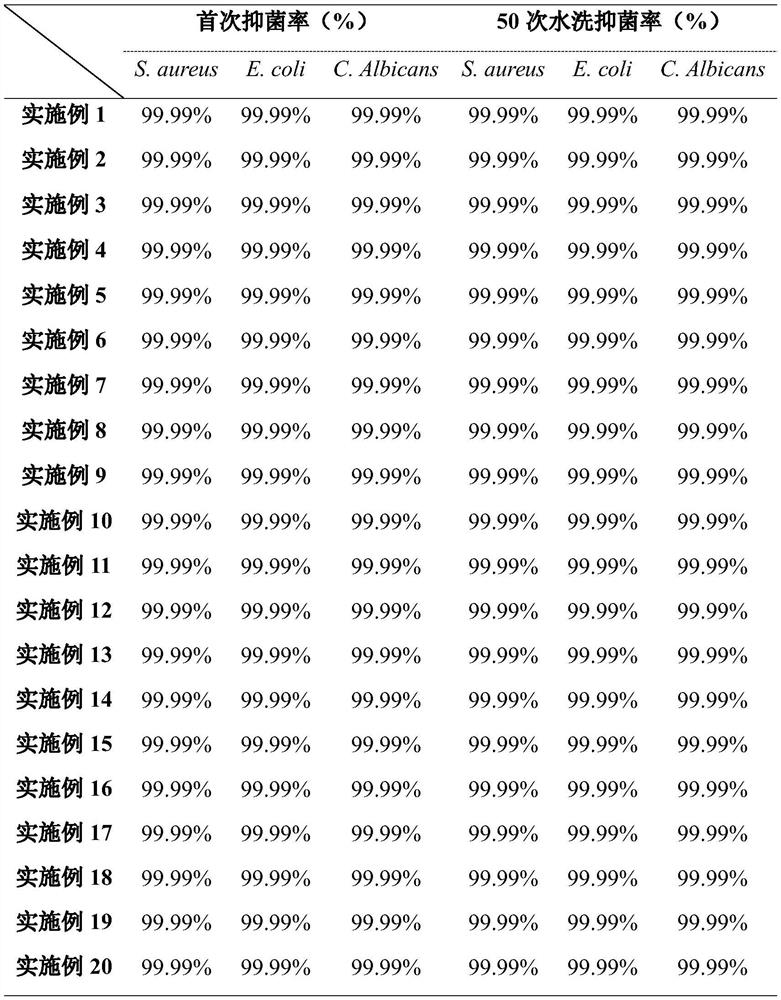

Embodiment 1

[0031] (1-1) ultrasonically disperse 2g / L copper oxide nanoparticle aqueous dispersion for 1 hour, until the copper oxide nanoparticles are uniformly dispersed in the solution, immerse the nylon fabric in the copper oxide nanoparticle-containing solution, and the copper oxide nanoparticles are uniformly attached on fabric fibers;

[0032] (1-2) Add formaldehyde solution in 0.04mol / L cresol solution, stir evenly, in the mixed solution (the mol ratio of cresol and formaldehyde is 1:3, then add the mixed solution into the step (1-1) system , adjust the pH of the system to above 7, react in the reaction kettle at 140 ° C for 8 hours, take out the fabric from the solution, wash and dry to obtain a wash-resistant antibacterial fabric.

Embodiment 2

[0034] (1-1) Ultrasonic disperse 3g / L silver nanoparticles water dispersion liquid for 1h, until the silver nanoparticles are uniformly dispersed in the solution, soak the cotton fabric in the solution containing silver nanoparticles, and the silver nanoparticles are evenly attached to the fabric fibers superior;

[0035] (1-2) Add furfural solution in 0.05mol / L gallic acid solution, stir evenly, the molar ratio of gallic acid and furfural in the mixed solution is 1:4, then add the mixed solution in the step (1-1) system, Adjust the pH of the system to above 7, react in a reactor at 80° C. for 24 hours, take out the fabric from the solution, wash and dry to obtain a washable antibacterial fabric.

Embodiment 3

[0037] (1-1) Ultrasonic disperse 4g / L zinc oxide nanoparticle aqueous dispersion liquid for 1h, until the antibacterial zinc oxide nanoparticle is uniformly dispersed in the solution, immerse the aramid fabric in the solution containing antibacterial zinc oxide nanoparticle, zinc oxide nanoparticle The particles are evenly attached to the fabric fibers;

[0038] (1-2) Add hexamethylenetetramine into 0.1mol / L gallic acid solution, the molar ratio of gallic acid to hexamethylenetetramine is 1:6, stir evenly and add into the system of step (1-1) , adjust the pH of the system to 7 or more, react in a reactor at 100°C for 12 hours, take out the fabric from the solution, wash and dry to obtain a washable antibacterial fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com