Polyurethane composition with controllable dispersed phase form as well as preparation method and application thereof

A polyurethane and dispersed phase technology, applied in the field of polyurethane, can solve the problems of general barrier properties, high barrier properties, damaged barrier properties, etc., to achieve low water vapor transmission rate and oxygen transmission rate, good heat aging resistance performance, the effect of excellent barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

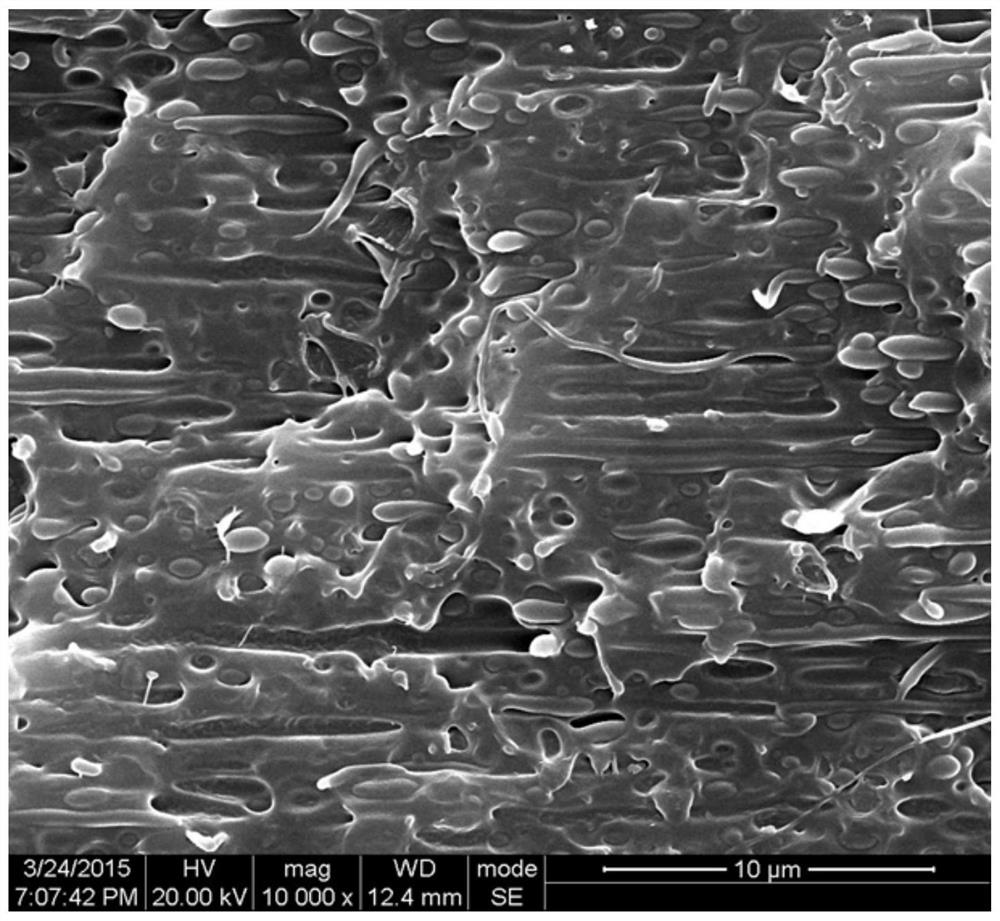

Embodiment 1

[0105] The mass percentage is 95% thermoplastic polyester polyurethane (1565IC), 3% ethylene-vinyl acetate copolymer and 2% polybutylene terephthalate are mixed uniformly, and the mixed composition is mm co-rotating twin-screw extruder for melt blending, the blending temperature is 170-235 ° C; the extruded sample is cooled by water, air-dried, and pelletized to obtain the composition pellets; after drying the pellets at 80 ° C for 16 hours , Film samples were obtained by casting and their related properties were tested. The plasticizing temperature of the casting machine is 165-185° C., the die temperature is 175° C., the melt temperature is 183° C., the traction roll speed is 3 m / min, the draw ratio L=3, and the cooling temperature is 20° C.

Embodiment 2

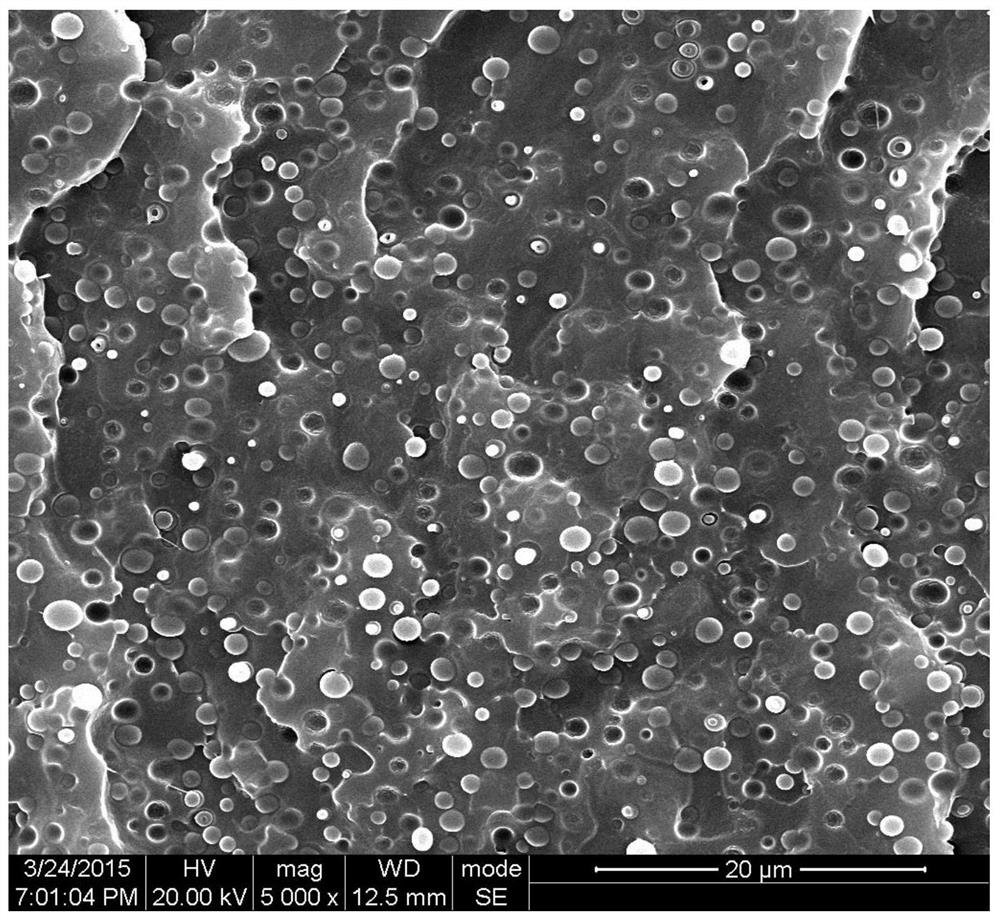

[0107] The thermoplastic polyester polyurethane (1185EC), 30% ethylene-ethyl acrylate copolymer and 20% low-melting point polyester polymer (L22) were mixed uniformly by mass percent, and the mixed composition was The melt blending is carried out in a corotating twin-screw extruder, and the blending temperature is 180-235°C. The extruded strip is cooled by water, air-dried, and pelletized to obtain composition particles. After the pellets were dried at 80°C for 16 hours, film samples were obtained by casting and their related properties were tested. The plasticizing temperature of the tape casting machine is 170-190°C, the die temperature is 180°C, the melt temperature is 188°C, the rotation speed of the traction roll is 15m / min, the draw ratio L=15, and the cooling temperature is 20°C.

Embodiment 3

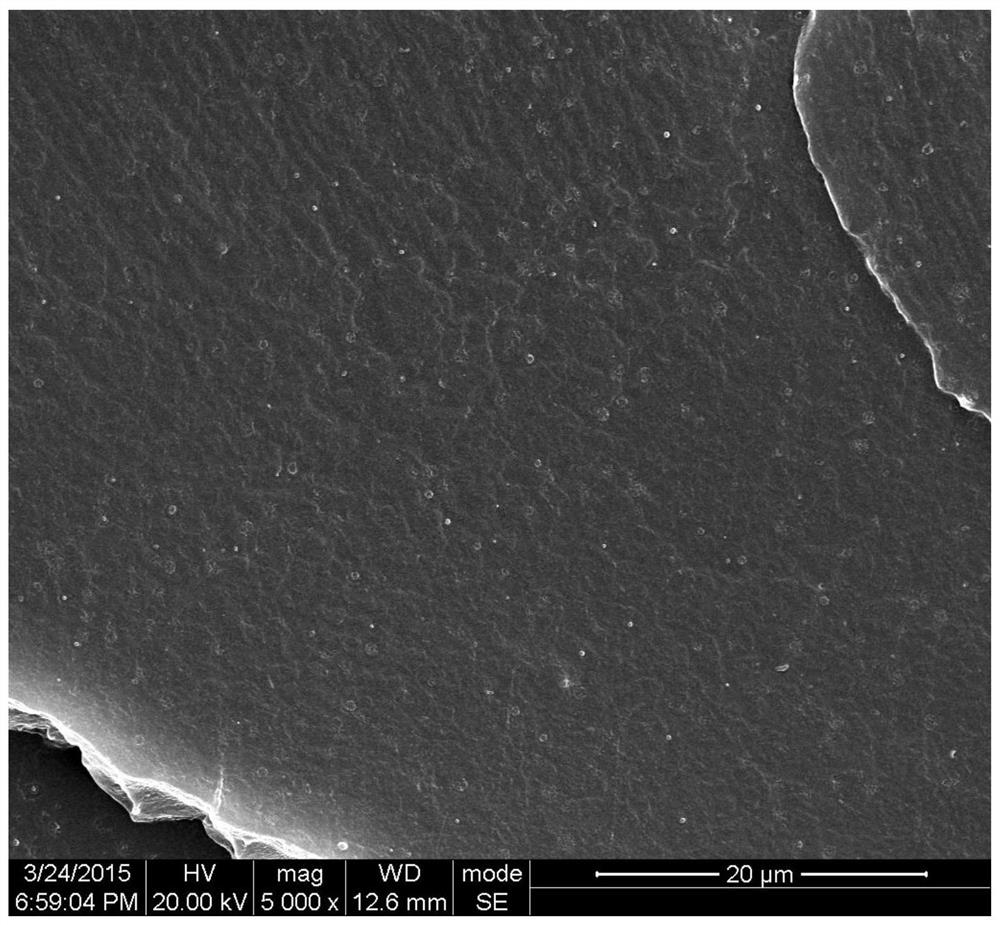

[0109] The thermoplastic polyether polyurethane (8190RV), 10% ethylene-butyl acrylate copolymer and 5% nylon 1010 were mixed evenly by mass percent, and the mixed composition was Melt blending is carried out in a co-rotating twin-screw extruder, and the blending temperature is 180-225°C; the extruded sample is cooled by water, air-dried, and pelletized to obtain composition particles; after drying the pellets at 80°C for 16 hours, Film samples were obtained by casting and their related properties were tested. The plasticizing temperature of the tape casting machine is 170-190°C, the die temperature is 180°C, the melt temperature is 188°C, the rotation speed of the traction roll is 3m / min, the draw ratio L=3, and the cooling temperature is 20°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com