Method for recovering tantalum, nickel and silver from waste tantalum capacitor

A tantalum capacitor and waste technology, which is applied in metallurgical engineering, chemical engineering and industrial solid waste resource utilization, can solve the problems of complex and lengthy process flow, high separation cost, failure to recycle, etc., and achieve high purity and low energy consumption , Inhibit the effect of halogenated volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

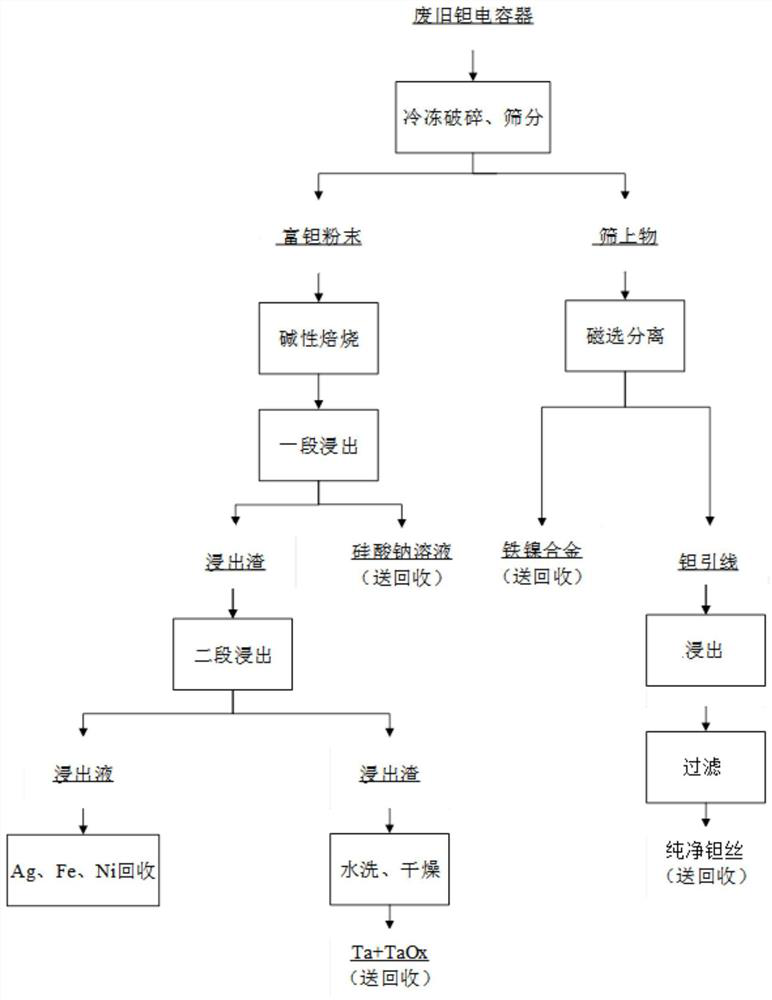

[0037] A method for reclaiming tantalum, nickel and silver in the waste tantalum capacitor of the present invention, the technological process is as follows figure 1 shown, including the following steps:

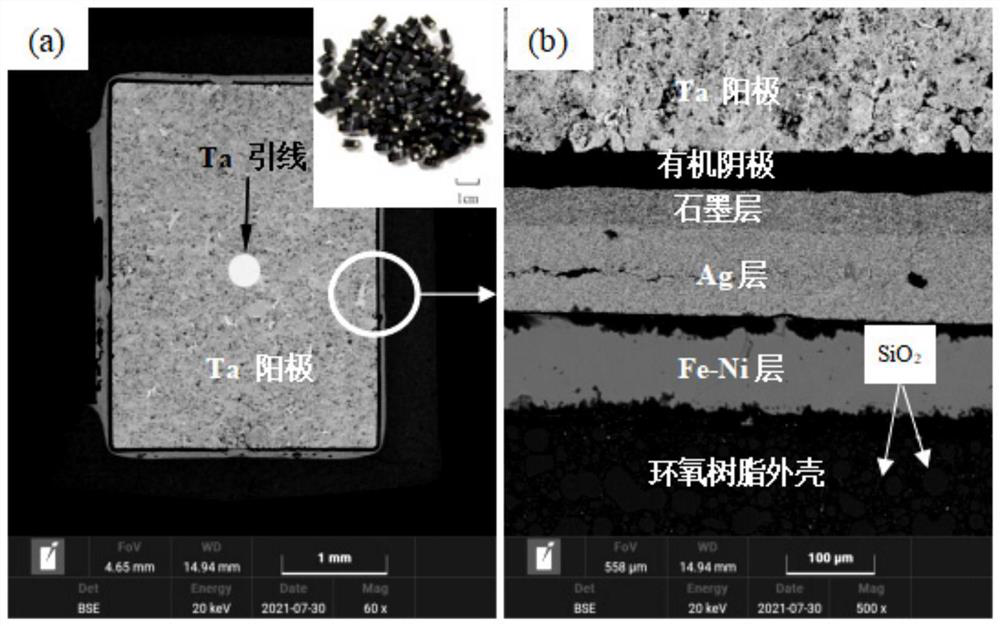

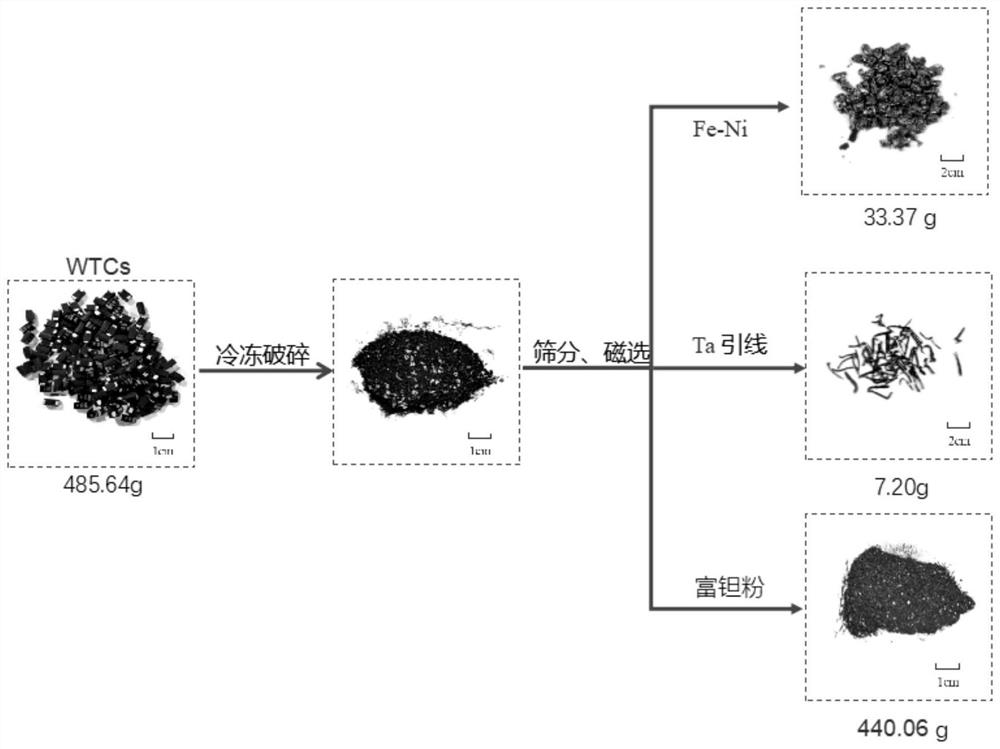

[0038] (1) A waste tantalum capacitor provided by a domestic waste electronics recycling company. It is a black chip tantalum capacitor with a withstand voltage of 4V and a capacitance of 1000μF produced by NEC TOKIN. The individual mass is 0.36g and the outer size is 7×4× 3mm. Take 485.64g of the above waste tantalum capacitors, freeze them in 1.46L liquid nitrogen for 10min, take them out, crush them, and sieve them to obtain 441.81g of under-sieve tantalum-rich powder and 40.57g of over-sieve materials respectively.

[0039] (2) The oversize was separated by magnetic separation to obtain 33.37 g of iron-nickel alloy and 7.20 g of tantalum lead wire. The composition of the tantalum-rich powder obtained above is (wt.%): Ta 43.68, Fe 0.25, Ni 0.54, Ag 2.98, SiO 2 22.50, ...

Embodiment 2

[0048] A method for reclaiming tantalum, nickel and silver in the waste tantalum capacitor of the present invention, the technological process is as follows figure 1 shown, including the following steps:

[0049] (1) A waste tantalum capacitor provided by a domestic waste electronics recycling company. It is a black chip tantalum capacitor with a withstand voltage of 4V and a capacitance of 1000μF produced by NEC TOKIN. The individual mass is 0.36g and the outer size is 7×4× 3mm. Take 485.64g of the above waste tantalum capacitors, freeze them in 1.46L liquid nitrogen for 10min, take them out, crush them, and sieve them to obtain 441.81g of under-sieve tantalum-rich powder and 40.57g of over-sieve materials respectively.

[0050] (2) The oversize was separated by magnetic separation to obtain 33.37 g of iron-nickel alloy and 7.20 g of tantalum lead wire. The composition of the tantalum-rich powder obtained above is (wt.%): Ta 43.68, Fe 0.25, Ni 0.54, Ag 2.98, SiO 2 22.50, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com