Flat lens capable of customizing aberration based on phase change material and manufacturing method thereof

A technology of phase-change materials and flat-panel lenses, which is applied in the field of microelectronics, can solve the problems that the single-layer structure cannot achieve phase regulation, cannot meet the needs of transmissive flat-panel lenses, and the electric field does not have non-volatile properties, so as to achieve beam convergence and facilitate Design and integration, the effect of high transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

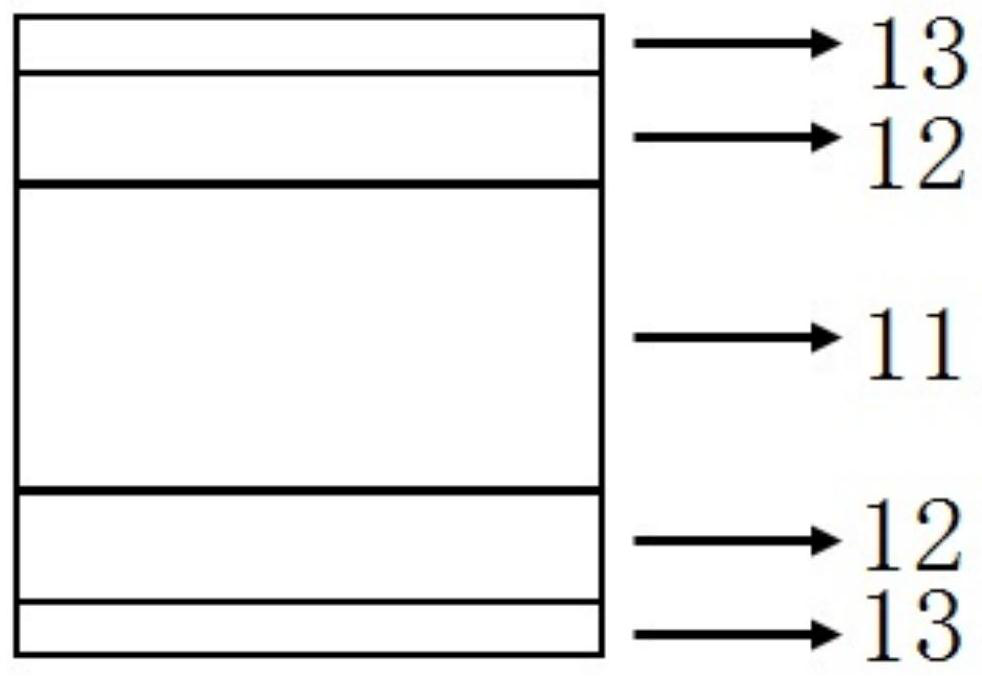

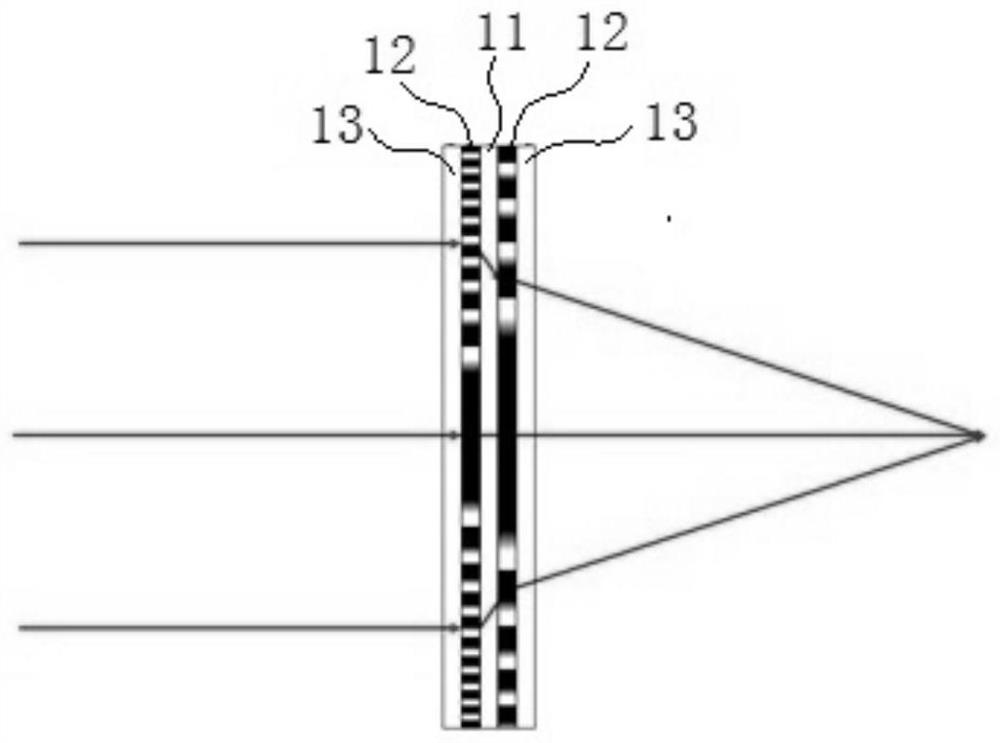

[0047] Such as figure 1 As shown, a flat plate lens 1 based on phase change material with customizable aberration, including:

[0048] A dielectric substrate 11, the dielectric substrate 11 can transmit light beams in the target wavelength band, and the target wavelength band is the working wavelength band of the flat lens 1;

[0049] A phase-change dielectric film 12 placed on the upper and lower surfaces of the dielectric substrate 11. Under the action of an external excitation signal, the phase-change material contained in the phase-change dielectric film 12 can exhibit different states, corresponding to the different states of the flat lens 1. Phase state; the external excitation signal is a laser signal that can cause a phase change in the phase change material in the phase change dielectric film 12, and the wavelength of the laser signal is a reconstruction band;

[0050] A cladding film 13 placed on the surface of the phase-change dielectric film 12, the cladding film ...

Embodiment 2

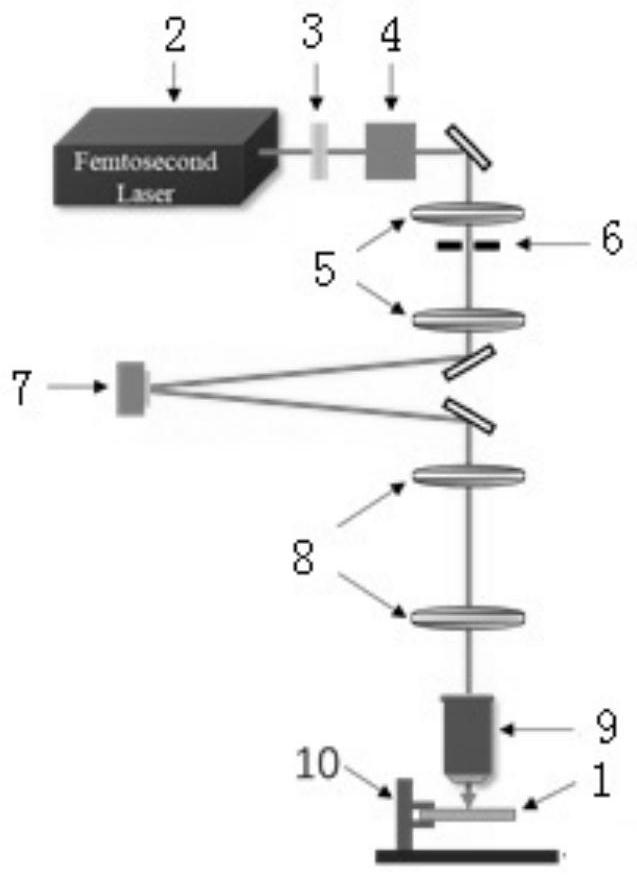

[0061] The present invention also provides a method for manufacturing a flat plate lens 1 based on a phase change material with customizable aberrations. In this embodiment, a phase change medium film 12 is prepared by vacuum thermal evaporation, including the following steps:

[0062] S1. Evaporate phase-change dielectric film 12 on the upper surface of dielectric substrate 11: place dielectric substrate 11 on the sample table on the vacuum coating machine and fix the substrate with clamps (wherein the dielectric substrate 11 is not pasted with blue film as the surface to be evaporated); The vacuum of the coating machine is pumped to 10-6pa; the phase-change material target glass is heated by heating the tantalum evaporation boat, and the film is deposited at an evaporation rate of 0.2-0.8A / s (preferably, the deposition rate is 0.5A / s) , the deposition rate and film thickness are monitored in real time by the film thickness meter inside the coating machine. The prepared phase...

Embodiment 3

[0069] The present invention also provides a method for manufacturing a flat plate lens 1 based on a phase-change material with customizable aberrations. In this embodiment, magnetron sputtering is used to prepare a phase-change medium film 12, which includes the following steps:

[0070] S1. Sputtering the phase-change dielectric film 12 on the upper surface of the dielectric substrate 11: fix the phase-change material target on the cathode, place the dielectric substrate 11 on the anode, and make the side of the dielectric substrate 11 to be sputtered face the target target surface; when the vacuum degree reaches 5x10-4Pa, pass in argon gas, turn on the ion source after the gas flow is stable, and start cleaning; after cleaning the belt, turn off the ion source, adjust the DC or RF power supply to the required power, and start the coating to the end of sputtering.

[0071] S2. Deposit cladding film 13: deposit a cladding film 13 of 2-5nm on the phase change dielectric film 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com