Method and application for green synthesis of nano platinum by using lotus aqueous extract

A technology of green synthesis and lotus flower extract, which is applied in the field of nano-platinum, can solve the problems that nanoparticles are not suitable for health care and beauty applications, high cost, adsorption of chemical reagents and dangerous by-products, etc., to achieve inhibition of tyrosinase activity and low cost The effect of low cost and simple production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Take the dried lotus flower powder, mix it with ultrapure water according to the mass ratio of 1:10 to obtain a mixed solution, and ultrasonicate at 0°C for 30 minutes;

[0057](2) Centrifuge at 8000 rpm for 10 minutes, take the supernatant, and freeze-dry to obtain the lotus extract dry powder;

[0058] (3) Weigh the lotus extract obtained in step (2), dissolve it in water at a ratio of 1:100 (w:v), and filter to obtain a lotus extract.

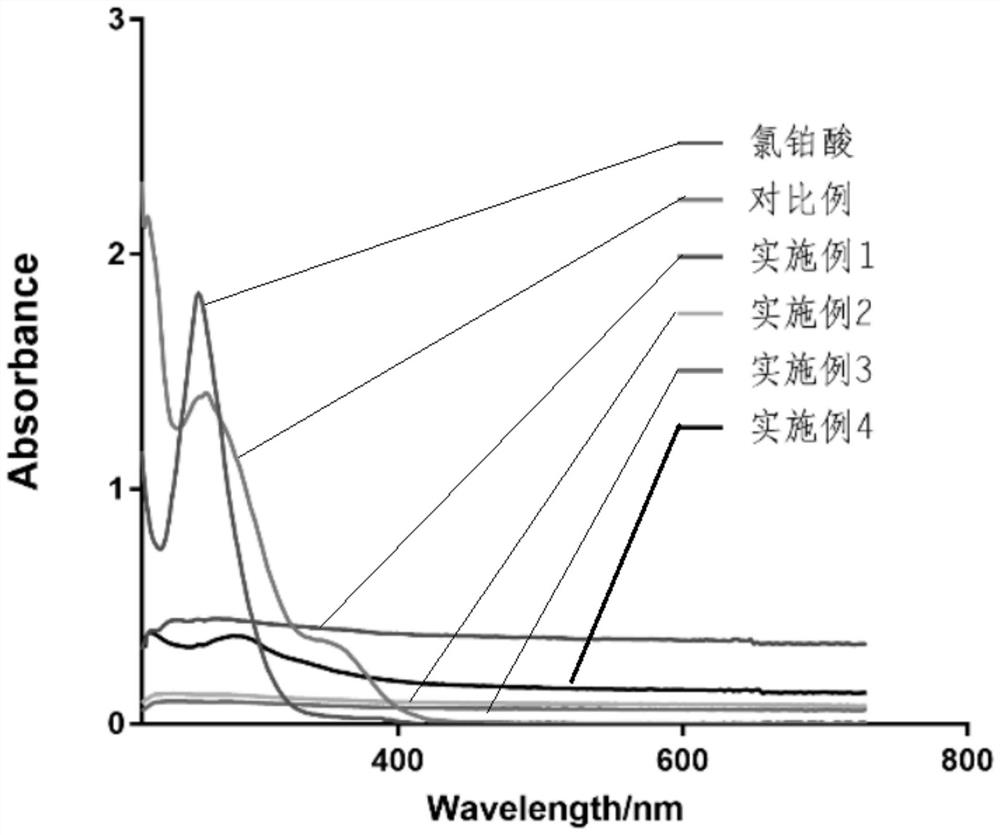

[0059] (4) Take 1 ml of the extract solution and add 0.001 mol of chloroplatinic acid, stir vigorously for 30 minutes, the reaction mixture turns from yellow to black, indicating the formation of platinum nanoparticles.

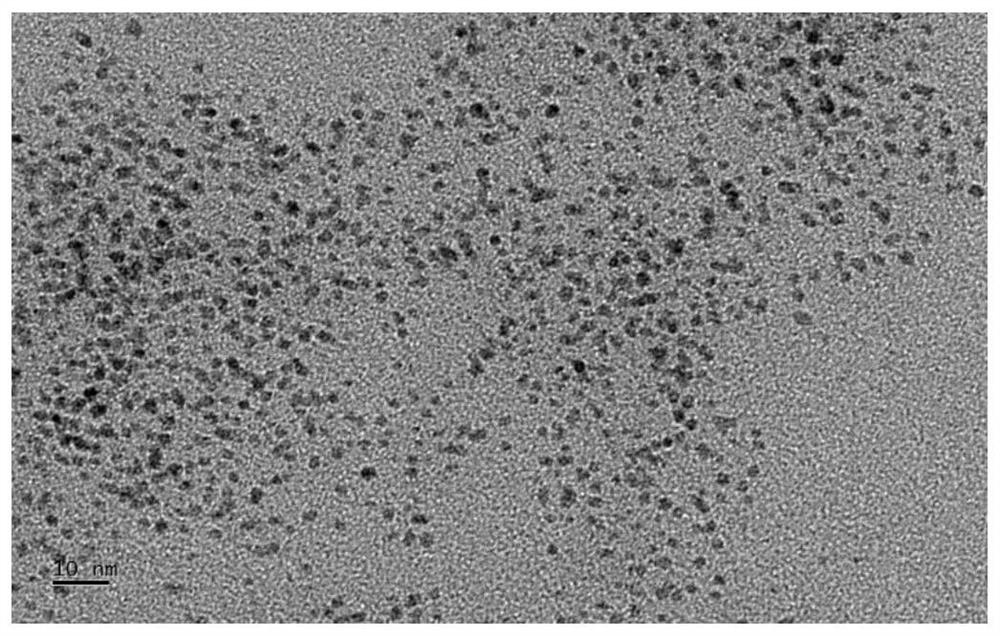

[0060] (5) Centrifuge the nano-platinum solution obtained in step (4) at 12,000 rpm for 20 minutes, wash the precipitate twice with pure water and then dissolve it in pure water to obtain the nano-platinum solution.

Embodiment 2

[0062] (1) Take the dried lotus flower powder, mix it with ultrapure water according to the mass ratio of 1:20 to obtain a mixed solution, and ultrasonicate at 30°C for 2 hours;

[0063] (2) Centrifuge at 10,000 rpm for 15 minutes, take the supernatant, and freeze-dry to obtain the lotus extract dry powder;

[0064] (3) Weigh the lotus extract obtained in step (2), dissolve it in water at a ratio of 2:100 (w:v), and filter to obtain the lotus extract.

[0065] (4) Take 2 ml of the extract solution and add 0.01 mol of chloroplatinic acid, stir vigorously for 1 hour, the reaction mixture turns from yellow to black, indicating the formation of nano-platinum.

[0066] (5) Centrifuge the nano-platinum solution obtained in step (4) at 12,000 rpm for 20 minutes, wash the precipitate twice with pure water and then dissolve it in pure water to obtain the nano-platinum solution.

Embodiment 3

[0068] (1) Take the dried lotus flower powder, mix it with ultrapure water according to the mass ratio of 1:50 to obtain a mixed solution, and ultrasonicate at 60°C for 4 hours;

[0069] (2) Centrifuge at 12,000 rpm for 20 minutes, take the supernatant, and freeze-dry to obtain the lotus extract dry powder;

[0070] (3) Weighing the lotus extract obtained in step (2), dissolving it in water according to 5:100 (w:v), and filtering to obtain the lotus extract;

[0071] (4) Take 3 ml of the extract solution and add 0.05 mol of chloroplatinic acid, stir vigorously for 2 hours, the reaction mixture turns from yellow to black, indicating the formation of nano-platinum.

[0072] (5) Centrifuge the nano-platinum solution obtained in step (4) at 12,000 rpm for 20 minutes, wash the precipitate twice with pure water and then dissolve it in pure water to obtain the nano-platinum solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com