Method for extracting dihydromyricetin from ampelopsis grossedentata

A technology of dihydromyricetin and rattan tea, applied in the direction of organic chemistry, etc., can solve the problems of flammability, no report on the extraction and preparation of dihydromyricetin, and environmental protection, and achieve the effect of easy preparation, low raw material price, and non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

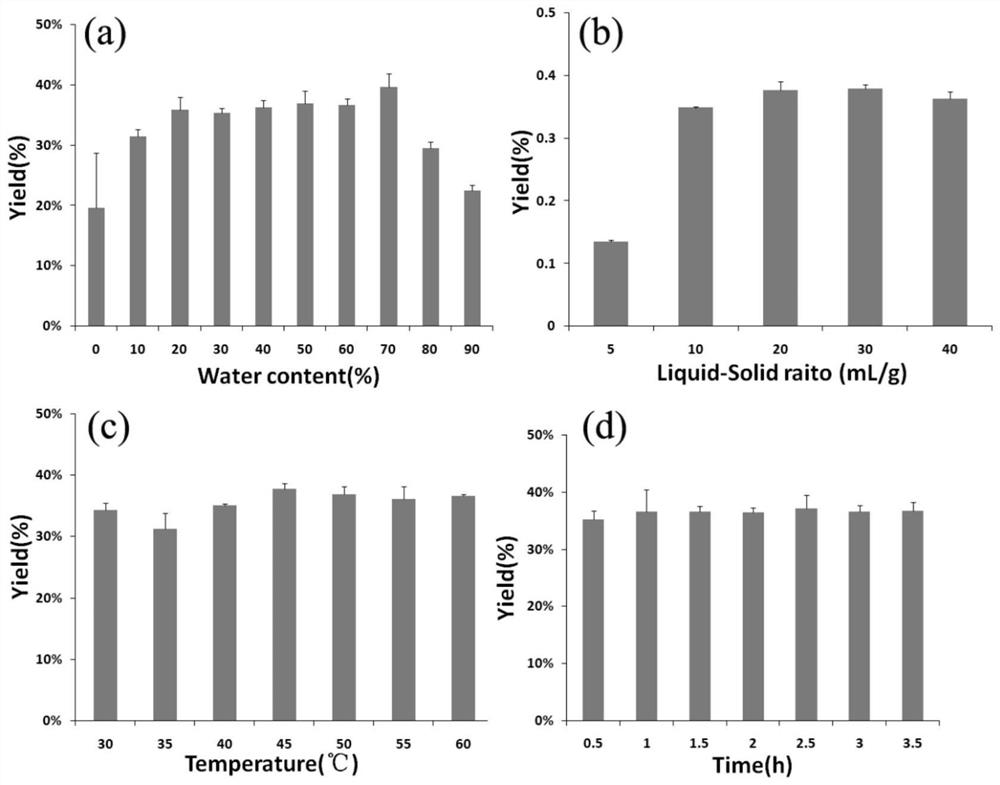

[0030] Embodiment 1: the selection of DES and the selection of DES extraction condition

[0031] (1) Preparation of deep eutectic solvent: mix the hydrogen bond acceptor and hydrogen bond donor uniformly in a certain molar ratio. The specific hydrogen bond acceptor and hydrogen bond donor and their molar ratio are shown in Table 1, and put into a sealed Shake in a glass bottle at 200 rpm at 80°C for 3 hours to obtain a pure and uniform liquid, and then stand at 30°C overnight. In this implementation, a total of 32 deep eutectic solvents were prepared for testing.

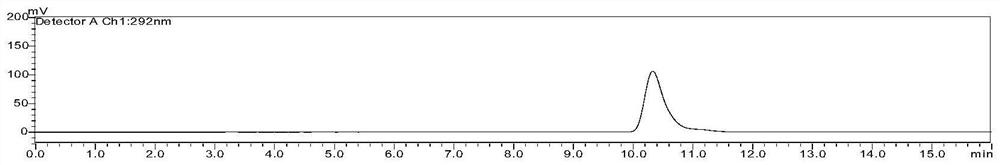

[0032] (2) Deep eutectic solvent extraction: the solution obtained in (1) and water are made into 30% (volume ratio) extraction solvent A, and the vine tea powder and extraction solvent A are mixed evenly at a material-to-liquid ratio of 1:20g / mL , at 45°C, shaking in a shaking table with a rotating speed of 200rpm for 2h to obtain the extract of dihydromyricetin, and the yield of dihydromyricetin in the extract wa...

Embodiment 2

[0052] Embodiment 2: the selection of macroporous resin and the selection of loading conditions

[0053] Macroporous resin separation: get No. 12 DES in the embodiment 1 as the dihydromyricetin extract 1mL that extractant obtains, load sample on macroporous resin successively with a large amount of distilled water, 80% ethanol elution (10mL), load sample After the ethanol elution part was collected to obtain eluate A, the eluate was concentrated to obtain concentrate B, and the yield of purity was determined.

[0054] (a) Screening of macroporous resin

[0055] Choose XAD1600N, XAD16, XAD1180, XAD7HP, D101, S-8, AB-8, DM301, X-5 nine kinds of macroporous resins, carry out the adsorption recovery experiment of dihydromyricetin extract, the result is AB-8, DM301 or XAD -7HP has a better effect on dihydromyricetin ( Figure 5 a). DM301 was reused 6 times, and the recovery rate was good ( Figure 5 b).

[0056] (b) Study on the influence of loading conditions

[0057] Specif...

Embodiment 3

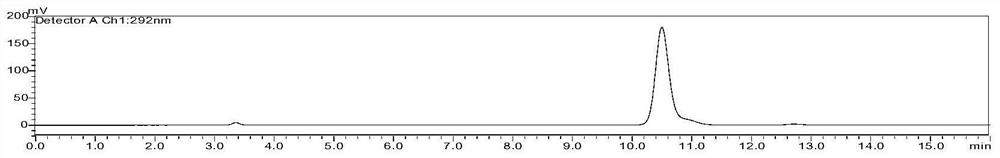

[0058] Embodiment 3: A kind of method extracting dihydromyricetin from rattan tea

[0059] 1) Preparation of DES: eutectic hydrogen bond acceptor tetrabutylammonium bromide and hydrogen bond donor pyruvate in a molar ratio of 1:2, the eutectic condition is: shaking at 200rpm in a shaker at 80°C for 3.5 hours to obtain DES , let stand overnight;

[0060] 2) DES extraction: the DES obtained in step 1) is mixed with water to form an extraction solvent with a concentration of 70%, then the vine tea powder and the extraction solvent are mixed evenly at a liquid-to-material ratio of 20mL / g, and the particle diameter of the vine tea powder is less than 1mm, the water content of rattan tea powder is 11%, 45 ℃, shaking in a shaker with a rotating speed of 200rpm for 2.5h, to obtain the extract of dihydromyricetin; the yield of dihydromyricetin in the extract is detected by HPLC to reach 40.09 %;

[0061] 3) Adsorption and separation of macroporous resin: take 1ml of the extract of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com