Silicone planar sealant for automobiles and preparation method of sealant

A technology of flat sealing and silicone, applied in the field of sealants, can solve the problems of unreachable, unable to delay the aging of sealants, poor heat resistance and anti-aging performance of flat sealants, etc., to achieve improved heat insulation effect and anti-aging Enhanced effect, heat resistance and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A car silicone flat sealant with a raw material comprising: 7 parts of three-membered ethyl propylene rubber, 7 parts of sulfurized methyl silicone rubber, 15 parts, α, ω-dihydroxy polyimethylsiloxane, 7 parts of the furnace, 4 parts of gas phase silica, 4 heat resistant agents, 4 parts of kaolin, 4 parts of methyltrimethoxysilane, 4 parts of transformer oil, 4 parts of methyl silicone, 4 parts of the aging agent, accelerator 4 parts, 4 parts of the crosslinking agent and 4 parts of the aminosilane coupling agent, the furnace black additive is a non-pollutant high-pose half-replenishing furnace black, the heat resistant agent is nano active calcium carbonate, the promoter is ethylene glycol dithionium Acid esters, crosslinking agents were 2,5-dimethyl-2,5 di-tert-butyl peroxide.

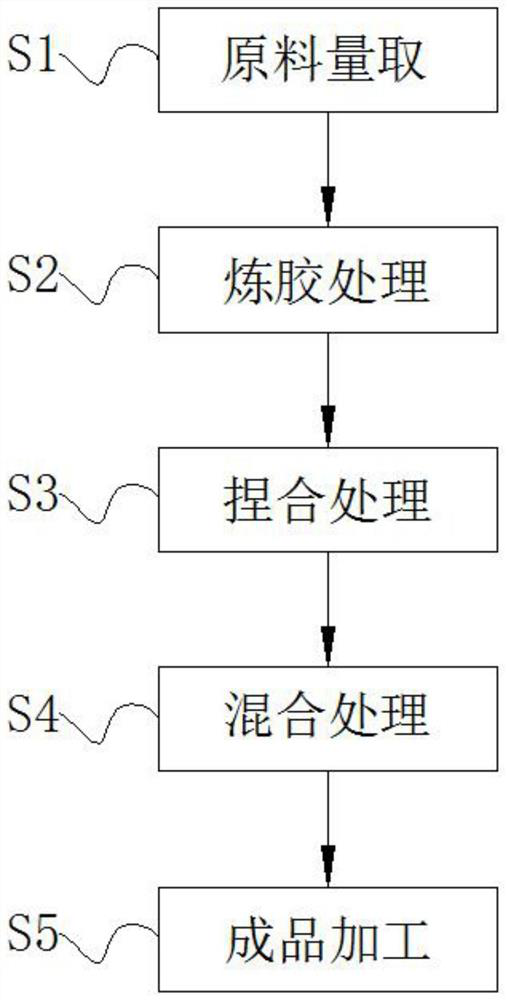

[0028] The embodiment of the present invention also discloses a method of preparing a silicone plane sealant for a car, and specifically includes the following steps:

[0029] S1, the amount of ra...

Embodiment 2

[0035] A car silicone flat sealant with a raw material comprising 5 parts by weight of 5 parts, 5 parts of sulfide rubber, α, ω-dihydroxy polydimethylsiloxane, 10 parts, α, ω-dihydroxy polyimethylsiloxane. 5 parts of the furnace, 3 parts of gas phase silica, 3 heat resistant agents, 3 parts of kaolin, 3 methyltrimethoxysilane, 3 transformer oil, 3 methyl silicone oil, 3 aging agents, Accelerator Three parts, 3 parts of the crosslinking agent and 3 parts of the amino silane coupling agent, the furnace black additive is a low-structure fast pressure furnace, the heat resistant agent is zinc oxide, the promoter is ethylene glycol diolic acid ester, crosslinking agent It is a benzoyl oxide.

[0036] The embodiment of the present invention also discloses a method of preparing a silicone plane sealant for a car, and specifically includes the following steps:

[0037] S1, the amount of raw material: First, by the ingredients, the required weight ratio is taken by the ingredients of the req...

Embodiment 3

[0043] A car silicone flat sealant with a raw material comprising: 10 parts of three-membered ethyl propylene rubber, 10 parts of sulfide rubber, α, ω-dihydroxy polyimethylsiloxane, 10 parts of the furnace, 5 parts of gas-phase silica, 5 heat resistant agents, 5 parts of kaolin, 5 parts of methyltrimethoxysilane, 5 transformer oil, 5 methyl silicone oil, 5 degreatment agents, promoters 5 parts, 5 parts of the crosslinking agent and 5 parts of the amino silane coupling agent, the furnace black additive is a high resistance furnace, the heat resistant agent is a nano-active calcium carbonate, the promoter is ethylene glycol dimercalate, cross-linking The agent is 2,5-dimethyl-2,5 di tert-butyl peroxide.

[0044] The embodiment of the present invention also discloses a method of preparing a silicone plane sealant for a car, and specifically includes the following steps:

[0045] S1, the amount of raw material: First, by the ingredients, the required weight ratio is taken by the ingre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com