Multi-pass gas-liquid phase absorption type trace element collection system and collection method

A trace element and collection system technology, applied in measurement devices, sampling devices, instruments, etc., can solve the problem of trace elements enrichment in filter membranes and filter membrane blockages, affecting test accuracy, sampling system stability, and affecting test results. Accuracy and other issues, to achieve the effect of eliminating the defects of lax sealing, full function and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

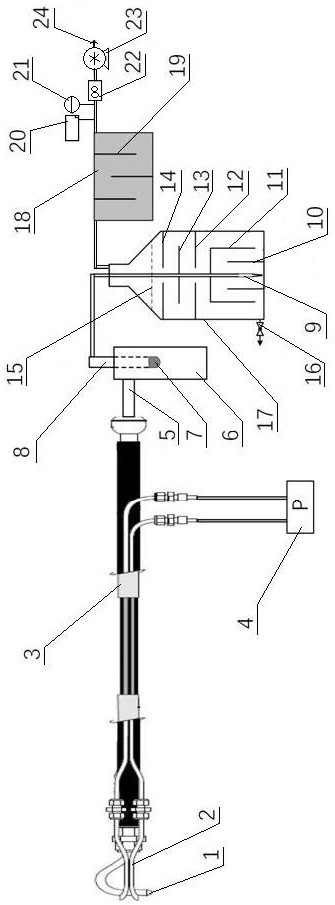

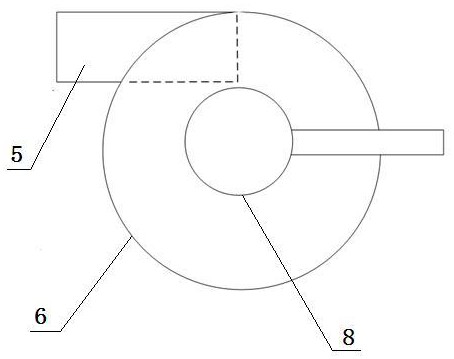

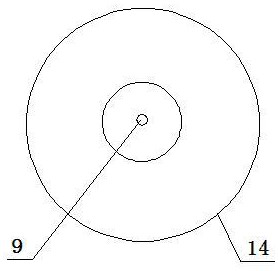

[0034] A multi-pass gas-liquid phase absorption trace element collection system, which consists of: a sampling head 1, one end of a pitot tube 2 is fixed on the sampling head, and a differential pressure gauge 4 is installed at the other end of the pitot tube , the sampling head is connected to the accelerating tube 5 through a connecting pipeline, the connecting pipeline wraps the heating layer 3 outside, and the accelerating tube sticks to the wall and extends into the fly ash separator 6 along a tangent, the described A separation cylinder 8 is installed above the fly ash separator, and a filter membrane 7 is installed at the bottom of the separation cylinder. The bottom of the separation cylinder is connected to the impact tube 9 through a connecting pipe, and the impact tube is installed in the mixing reactor. In 17, the mixing reactor is sequentially installed with a primary mixing hood 10, a secondary mixing hood 11, a primary mixing pan 12, a secondary mixing pan 13, an...

Embodiment 2

[0036] According to the multi-pass gas-liquid phase absorption trace element collection system described in Example 1, the top of the mixing reactor is connected to one end of the drying box 18 through a connecting pipe, and the other end of the drying box is connected to the pressure gauge 20, Thermometer 21, flowmeter 22, vacuum pump 23, described vacuum pump is connected with evacuation pipe 24, and described dry box interior is equipped with 3 partitions 19 successively, and described partitions are arranged in parallel, and described mixing reactor A drain valve 16 is connected below, and the liquid level 15 is set on the upper part of the three-stage mixing plate.

[0037]The diameter of the accelerating tube is smaller than that of the previous pipeline, and the wall is attached to the inside of the separator along a tangent line. The lower part of the separating cylinder is covered with a detachable cylindrical filter membrane. The mixing reactor is equipped with 5% (V...

Embodiment 3

[0051] According to the collection method of the multi-pass gas-liquid phase absorption type trace element collection system described in embodiment 1-2, the method comprises the following steps:

[0052] Step 1: Add 5% HNO to the Mixed Reactor 3 and 10%H 2 o 2 Absorbing liquid, from the liquid level to the top 20mm of the third-stage mixing plate, fill the drying box with dried water-absorbing and discoloring silica gel particles;

[0053] Step 2: Block the sampling head with the rubber rod, turn on the vacuum pump to evacuate the system, turn off the vacuum pump when the vacuum degree of the pressure gauge is 50kPa, observe for 5 minutes, the pressure does not drop, the system leakage rate is not more than 3%, and the airtightness of the system is qualified; otherwise, Carry out a leak check on the sampling system, and the next step can only be carried out if the leak rate is qualified;

[0054] Step 3: Insert the sampling head into the target sampling place of the flue, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com