Nanometer nickel cluster and vanadium carbide particle modified ultrathin carbon layer composite material, and preparation method and application thereof

A composite material, vanadium carbide technology, applied in chemical instruments and methods, nanotechnology, nanotechnology, etc., can solve the problems of uncontrollable VC morphology, reduced catalytic activity, poor electrical conductivity of metal carbides, unfavorable electron transfer, etc. Hydrogen evolution performance, the effect of improving hydrogen evolution activity, excellent catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

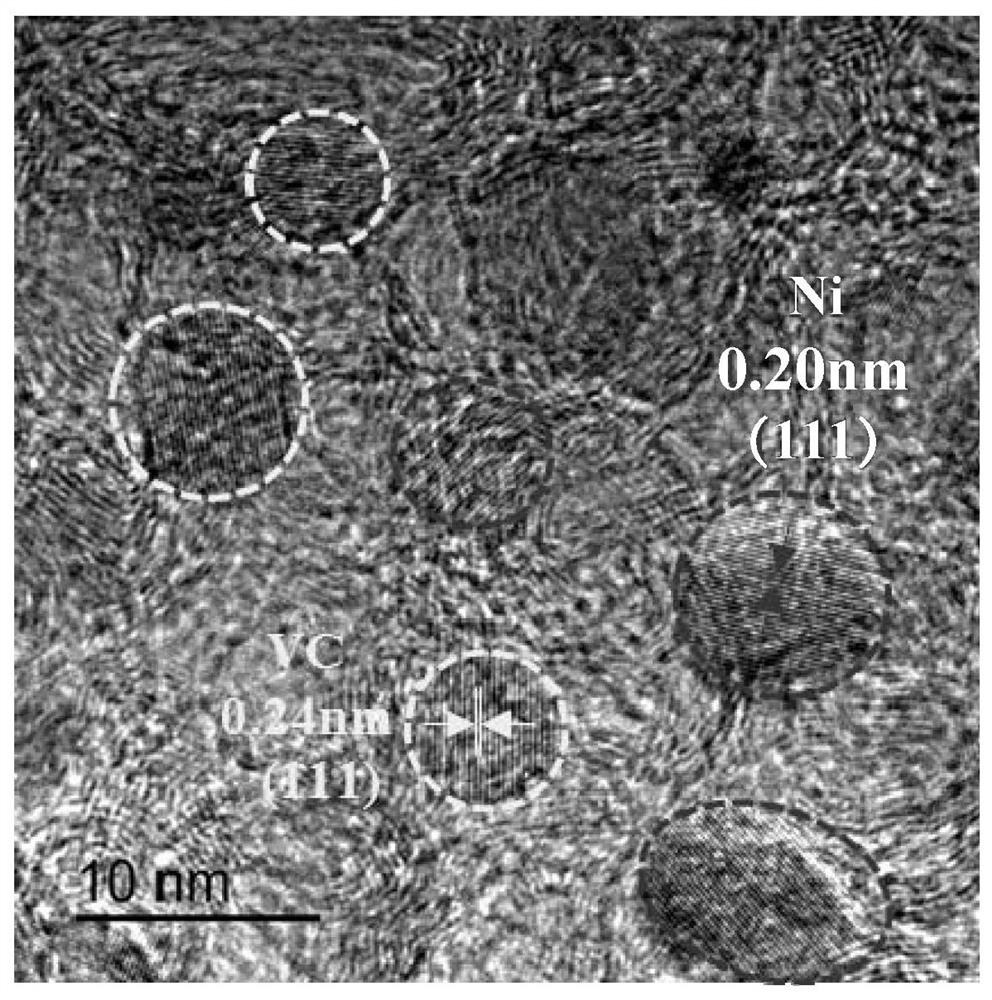

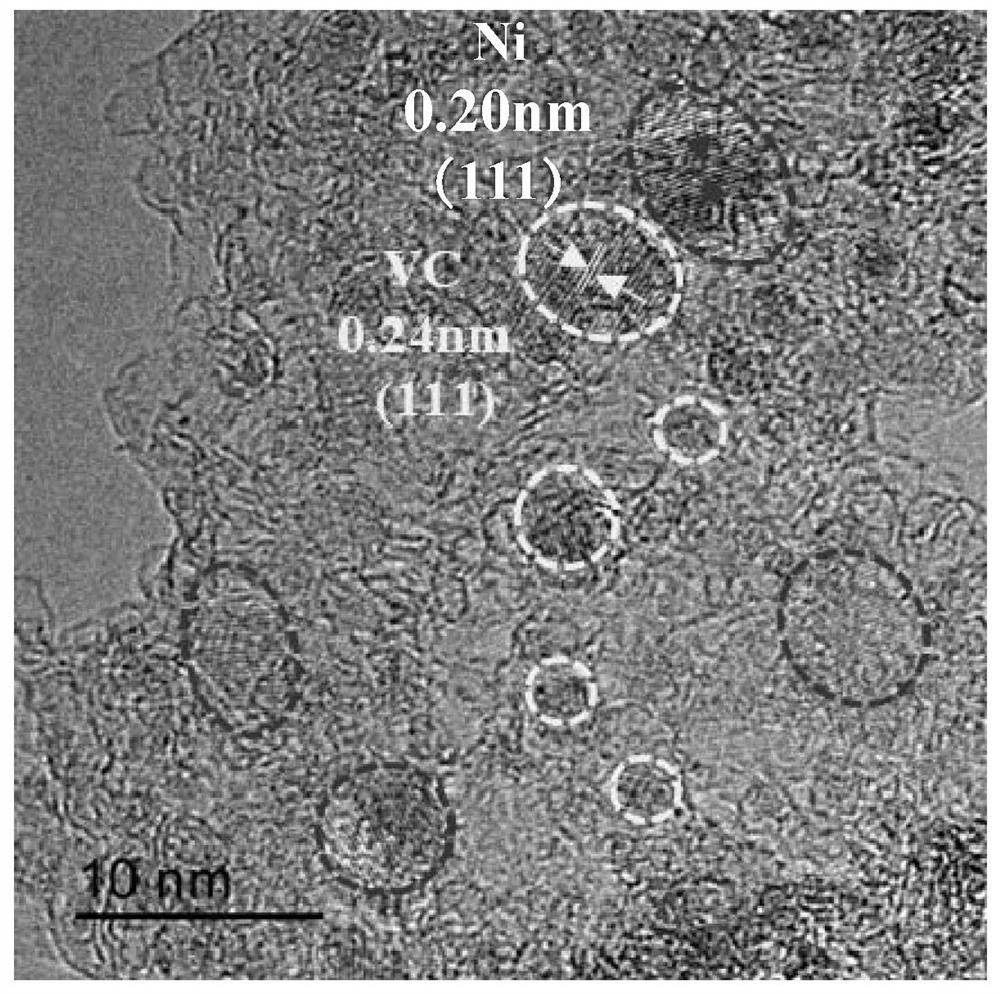

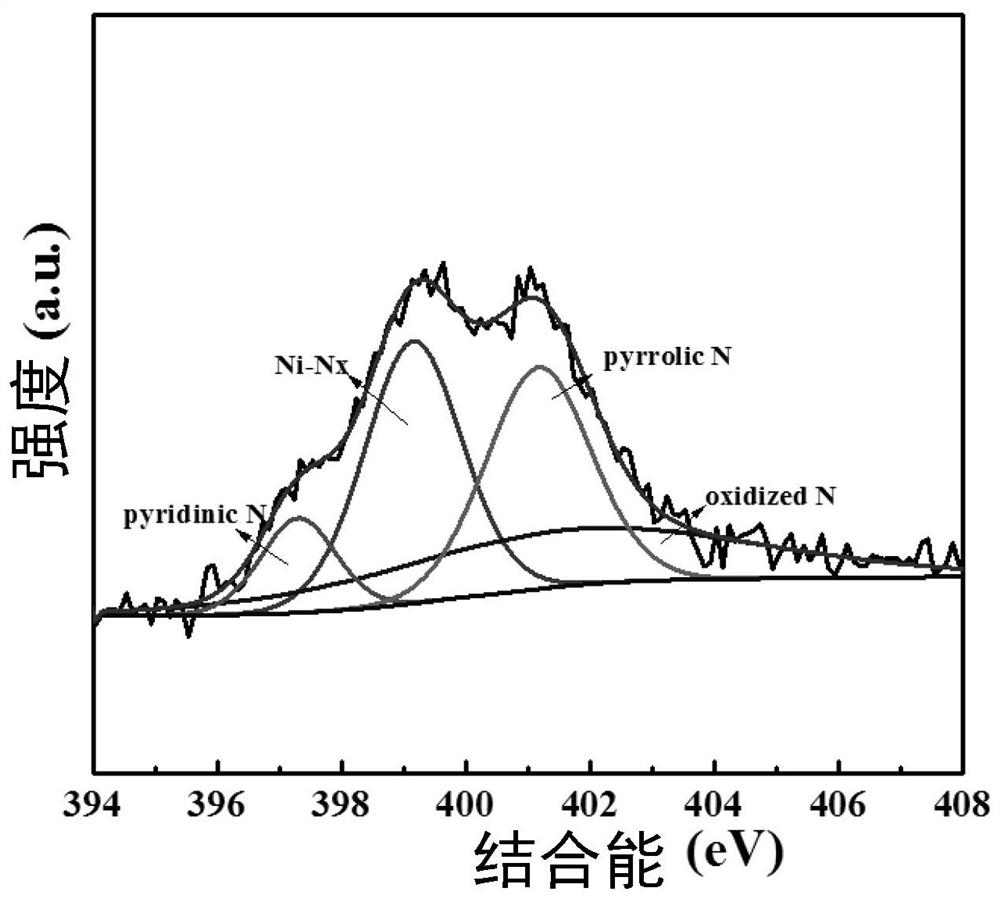

Method used

Image

Examples

preparation example Construction

[0037] Preparation of nickel vanadium double hydroxides. After mixing nickel source, vanadium source, alkali source and solvent, microwave hydrothermal reaction at 90-110 DEG C to obtain nickel vanadium double metal hydroxide. Wherein, the nickel source is selected from nickel nitrate hexahydrate, nickel sulfate hexahydrate, or nickel chloride hexahydrate. The vanadium source can be vanadium chloride and the like. The alkali source is urea. The molar ratio of nickel source, vanadium source and alkali source is (0.5-2):1:(1.5-1.6). The microwave hydrothermal reaction time can be 2-4 hours, and the power is 200-400W.

[0038] Preparation of Precursor A. The obtained nickel-vanadium double metal hydroxide is subjected to ultrasonication in ethanol solution for 1-2 hours, the ultrasonic temperature is 60-80°C, and the ultrasonic power can be 180-200W. After drying at room temperature, the pretreated double metal hydroxide was finally obtained, denoted as precursor A.

[0039...

Embodiment 1

[0045] Mix nickel chloride hexahydrate, vanadium chloride and urea according to the molar ratio of 0.5:1:1.56 and add them into 25ml of ultrapure water and stir for 15 minutes to obtain solution A; put the stirred solution A in a microwave reactor, React at 110°C for 4 hours, with a power of 400W. After cooling to room temperature, wash with ultrapure water and absolute ethanol for 3 times, and dry in a vacuum oven for 5 hours to obtain nickel vanadium double metal hydroxide;

[0046] Ultrasonic the nickel-vanadium double metal hydroxide in ethanol solution for 2 hours, the ultrasonic temperature is 60°C, the ultrasonic power is 180W, and then dried at room temperature to finally obtain the precursor A;

[0047] Dicyandiamide and precursor A were mixed according to a mass ratio of 2:1 and fully ground for 30 minutes to obtain a mixed raw material;

[0048] Put the mixed raw materials in a porcelain boat, and put them in a tube furnace for 30 minutes under the argon protective ...

Embodiment 2

[0051] Mix nickel chloride hexahydrate, vanadium chloride and urea in a molar ratio of 1:1:1.56 and add them into 25ml ultrapure water and stir for 15 minutes to obtain solution A; put the stirred solution A in a microwave reactor, React at 110°C for 4 hours, with a power of 400W. After cooling to room temperature, wash with ultrapure water and absolute ethanol for 3 times, and dry in a vacuum oven for 5 hours to obtain nickel vanadium double metal hydroxide;

[0052] Ultrasonic the nickel-vanadium double metal hydroxide in ethanol solution for 2 hours, the ultrasonic temperature is 60°C, the ultrasonic power is 180W, and then dried at room temperature to finally obtain the precursor A;

[0053] Dicyandiamide and precursor A were mixed according to a mass ratio of 4:1 and fully ground for 30 minutes to obtain a mixed raw material;

[0054] Put the mixed raw materials in a porcelain boat, and put them in a tube furnace for 40 minutes under the argon protective atmosphere; Min ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com