Production method of glycine

A glycine and amino acid technology, applied in the biological field, can solve the problems of high toxicity of the substrate aminoacid, inactivation of microbial enzymes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

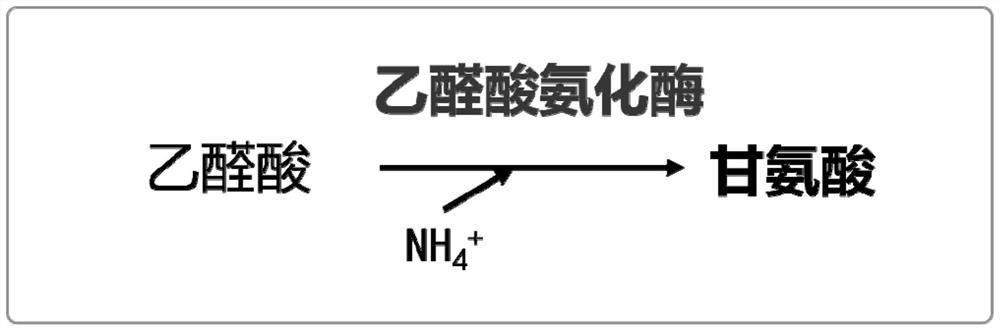

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0106] Embodiment 1, the whole gene synthesis of glyoxylate ammonialase gene on the expression plasmid

[0107] Will be derived from Aeromonas veronii, Bacillus aquimaris, Bacillus cereus, Bacillus flexus, Bacillus licheniformis, Bacillus velezensis, Bacillus substilis, Geobacillus stearothermophilus, Halomonas boliviensis, Labrenzia aggregata, Lysinibacillus fusiformis, Pseudomonas aeruginosa, Paucisalibacillus globuius, smegmatis Mycobacterium smegmatis and Mycobacterium tuberculosis glyoxylate ammonialase gene ald (stop codon removed) were synthesized between NdeI and XhoI of pET30a(+) (GenScript) and verified by sequencing After being correct, the corresponding plasmids pET30a-Avald, pET30a-Ba ald, pET30a-Bc ald, pET30a-Bf ald, pET30a-Bl ald, pET30a-Bv ald, pET30a-Bs ald, pET30a-Gs ald, pET30a-Hb were obtained in sequence ald, pET30a-La ald, pET30a-Lf ald, pET30a-Pa ald, pET30a-Pg ald, pET30a-Ms ald and pET30a-Mt ald (Table 1). These plasmids were respectively transforme...

Embodiment 2

[0109] Embodiment 2, analysis of glyoxylate ammonialase enzyme activity

[0110] Glyoxylate ammonase expression bacterial strain Av, Ba, Bc, Bf, Bv, Bl, Bs, Gs, Hb, La, Lf, Pa, Pg, Ms, Mt of the different sources of glyoxylate ammonialase obtained in embodiment 1 carry out glyoxylate Enzyme activity analysis of ammonase (Ald).

[0111] The single clone of the inoculated strain was cultured in LB liquid medium (the final concentration of kanamycin was 50mg / L) at 37°C and 250rpm until OD550=0.1, and the inducer IPTG was added with a final concentration of 0.1mM, and the culture was continued until logarithmic Expect. Take 30ml culture solution in a 50ml centrifuge tube, centrifuge at 10,000rpm at 4°C for 5min, discard the supernatant, collect the bacteria, wash twice with 15ml 100mM Tris-HCl buffer, suspend the bacteria in 3ml 100mM Tris-HCl , sonicate in an ice bath (power: 25W; on: 1s; off: 3s) for 3-5min until clarification, centrifuge at 10,000rpm for 20min at 4°C, and col...

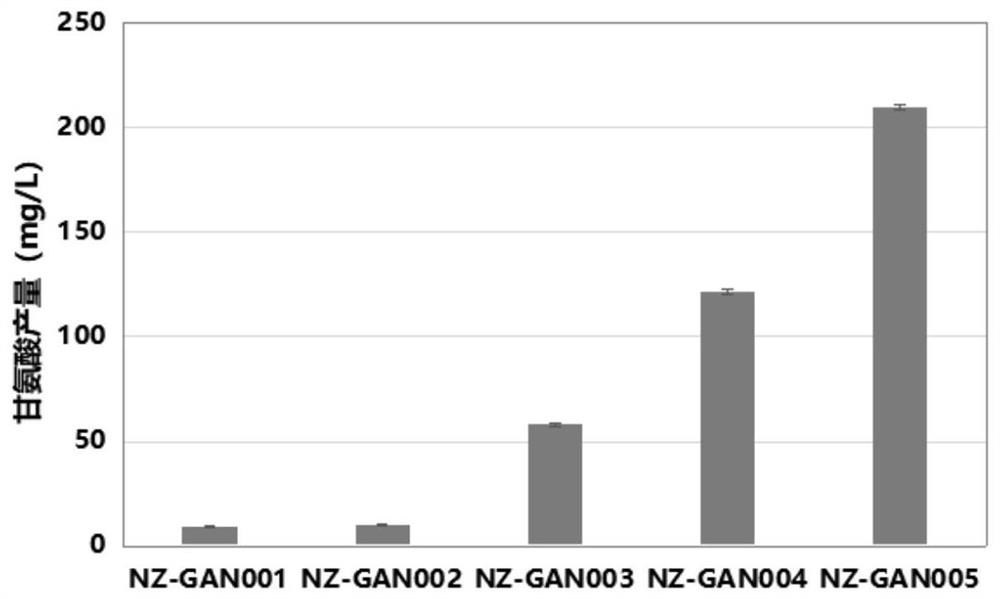

Embodiment 3

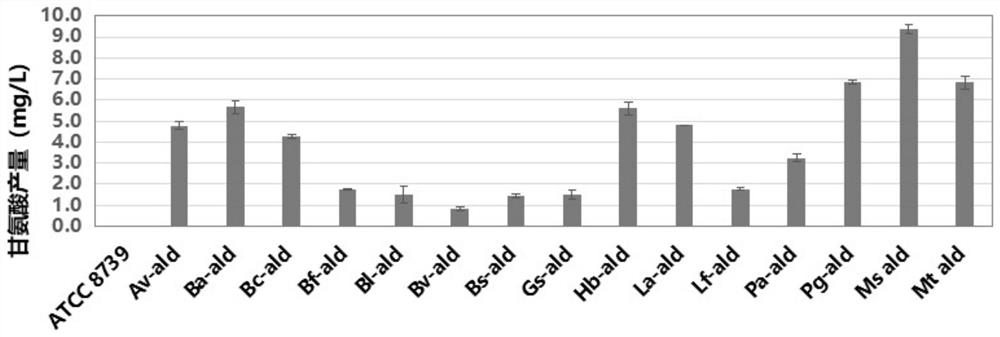

[0118] Embodiment 3, glyoxylate ammonialase (Ald) catalyzes and produces glycine in vitro

[0119] The glyoxylate ammoniaase pure enzymes obtained in Example 2 from different sources were catalyzed in vitro, and the yield of glycine synthesis was determined.

[0120] Glyoxylate ammoniation enzyme in vitro catalyzed glycine production reaction system is: 1.5ml centrifuge tube, add reaction buffer 990μl (40mM potassium phosphate buffer, 400mM ammonium sulfate, 0.2mM NADPH, 50mM sodium glyoxylate; pH7.0), Add 10 μl of 3U pure glyoxylate ammoniaase, react for 10 min, and perform amino acid analysis on an amino acid analyzer (Hitachi Automatic Amino Acid Analyzer L-8900) to detect the yield of glycine.

[0121] The ability to produce glycine in vitro can be achieved by in vitro catalysis of pure glyoxylate ammoniaase enzymes from different sources. Derived from Aeromonas veronii, B. aquimaris, B. cereus, B. flexus, B. licheniformis, B. velezensis, Bacillus subtilis B.substilis, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com