Metal element doped alkali metal ion battery negative electrode material and preparation method thereof

A technology of alkali metal ions and metal elements, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low doping content of metal elements, inability to fix metal elements firmly, poor uniformity and stability, and achieve Low impedance, excellent reversibility, effects of ensuring uniformity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of the alkali metal ion battery negative electrode material doped with metal elements comprises the following steps:

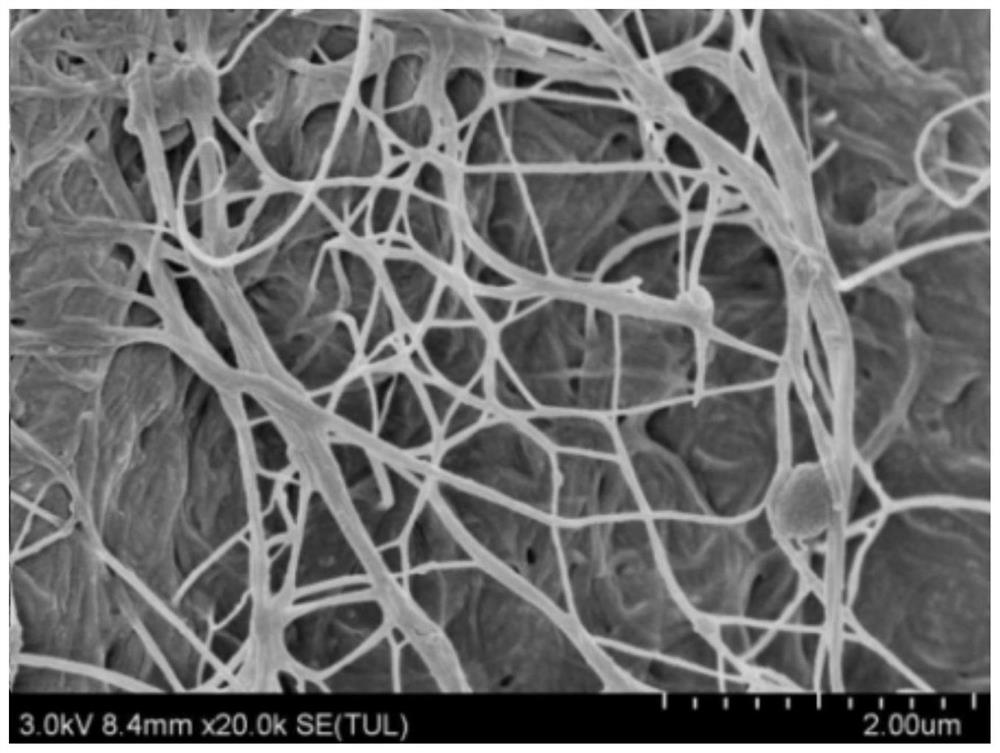

[0038] (1) Add bacterial cellulose (BC) flakes to Tris-HCl buffer solution, then add dopamine (DA), stir and react to obtain BC / PDA composite material

[0039] 1) Wash the bacterial cellulose membrane repeatedly with deionized water, soak it in 0.1mol / L NaOH solution, and heat it to 90°C in a constant temperature water bath for 90 minutes in a water bath to remove the bacteria and other impurities remaining in the bacterial cellulose membrane, take it out and cool it Repeatedly wash with deionized water until the bacterial cellulose is neutral, i.e. PH=7, to obtain a purified bacterial cellulose membrane, cut the purified bacterial cellulose membrane into 2cm×4cm bacterial cellulose sheets, and soak in deionized reserve in water;

[0040] 2) Add bacterial cellulose flakes to Tris-HCl buffer solution with a pH of 8.5, then add dop...

Embodiment 2

[0056] This example is basically the same as Example 1, except that in step (2), 6 pieces of BC / PDA composite materials are placed in 0.08mol / L copper nitrate solution for soaking reaction to obtain BC / PDA / Cu composite Material.

[0057] The carbonized BC / PDA / Cu composite material is prepared into a potassium ion battery, and the cycle number-capacity / efficiency test is performed, such as Figure 11 As shown, in the first charge and discharge process after being placed for 8-10 hours, the discharge specific capacity is as high as 500mAh / g, and the efficiency of the battery will increase with the increase of the cycle number, even exceeding 100%. In the battery capacity-voltage test, the fast sweep 500mA / g and the slow sweep 50mA / g can maintain 80-90% of the capacity well, indicating that the sintered carbonized BC / Cu composite material is used as the negative electrode material of the potassium ion battery Has good capacitance retention.

Embodiment 3

[0059] This example is basically the same as Example 1, except that in step (2), 6 pieces of BC / PDA composite materials are placed in 0.05mol / L ferric nitrate solution for soaking reaction to obtain BC / PDA / Fe composite Material.

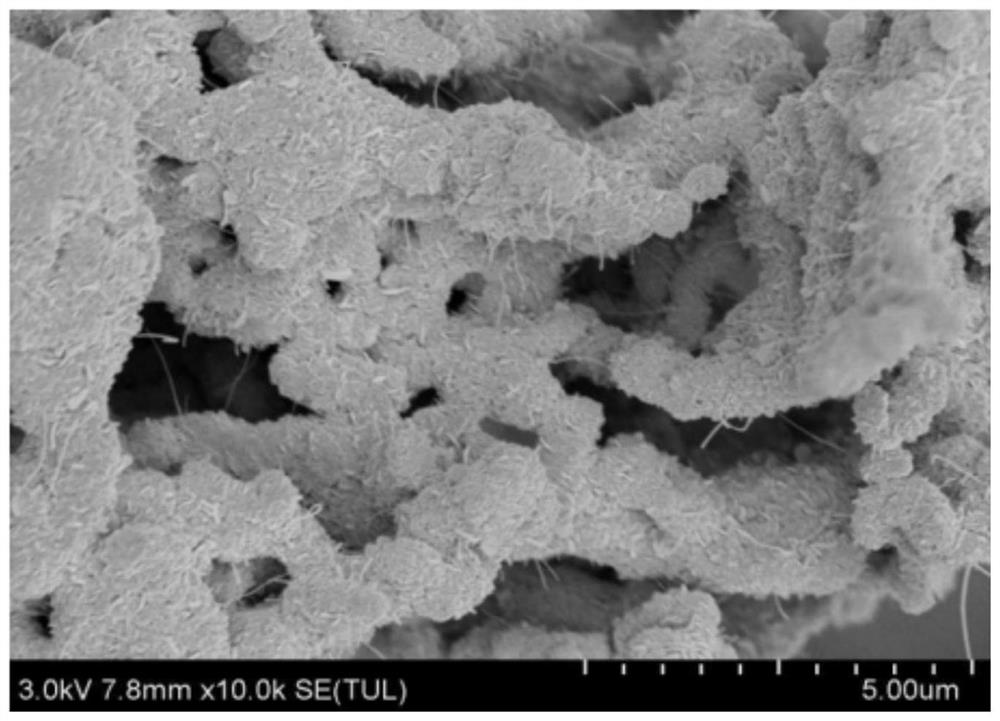

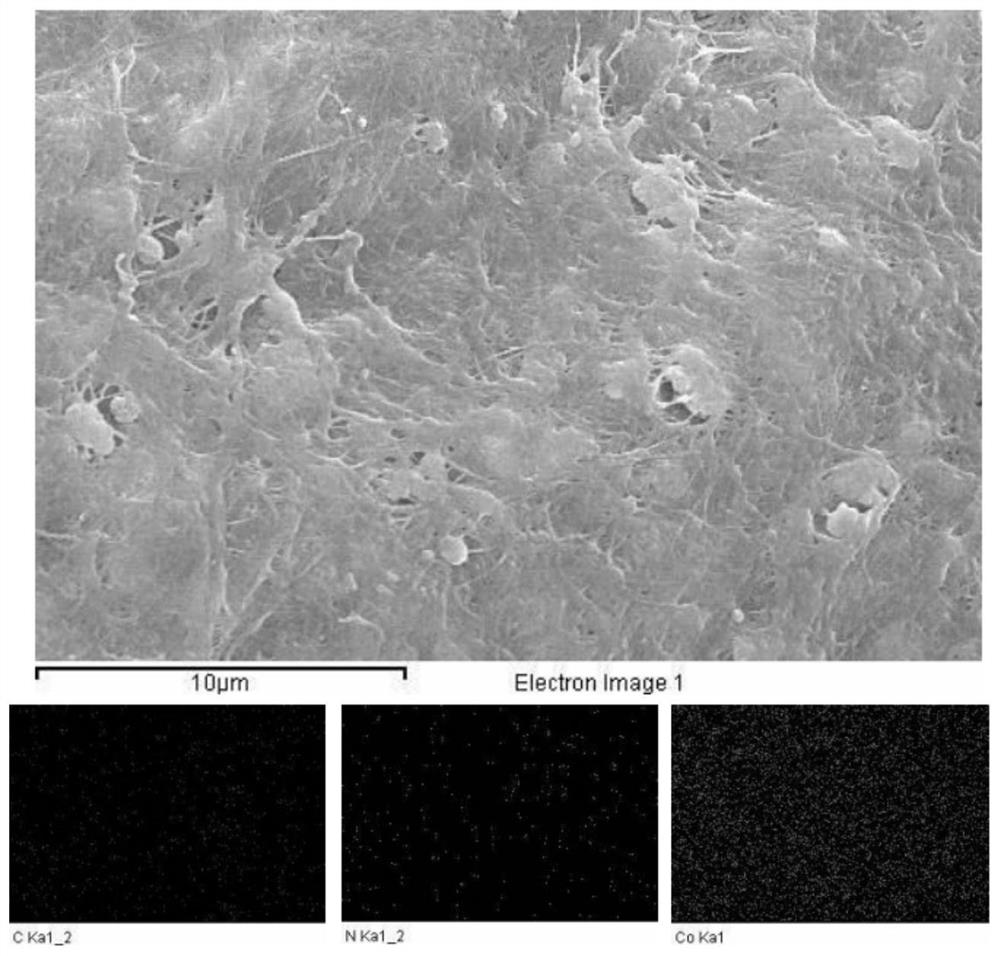

[0060] Carry out XRD test to the BC / PDA / Cu composite material after carbonization, the X-ray diffraction pattern is as follows Figure 12 shown, from Figure 12 It can be seen that the crystallization peak of elemental Fe appears at the position of 44.66°, and the crystallization peak of ferric oxide (Fe 3 o 4 ) crystallization peak. It shows that in the carbonized BC / PDA / Cu composite material, Fe is composed of iron and Fe 3 o 4 Existing in the same way, the characteristic crystallization peak of BC becomes weaker, which may be the reduced elemental iron and Fe 3 o 4 Attaches to the surface of composite fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com