Indium zinc sulfide/zinc ferrite composite photocatalyst as well as preparation method and application thereof

An indium zinc sulfide, photocatalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of easy rapid recombination of electrons and holes, reduce photocatalytic activity, etc., and achieve good application prospects and potential, low cost, and high catalytic degradation activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a preparation method of indium zinc sulfide / zinc ferrite composite photocatalyst, comprising the following steps:

[0027] a) After mixing iron source, zinc source and polyvinylpyrrolidone in the presence of the first solvent, electrospinning is carried out, and then calcined to obtain ZnFe 2 o 4 Nanofibers;

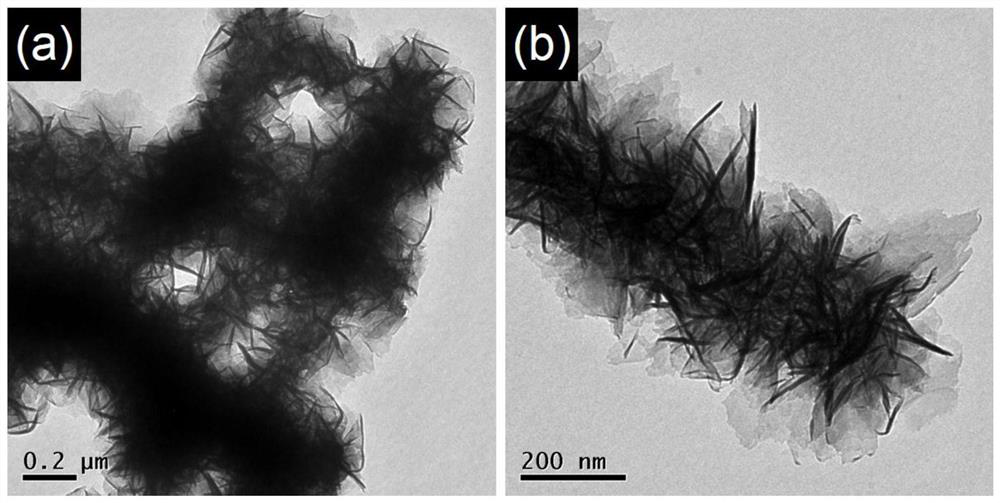

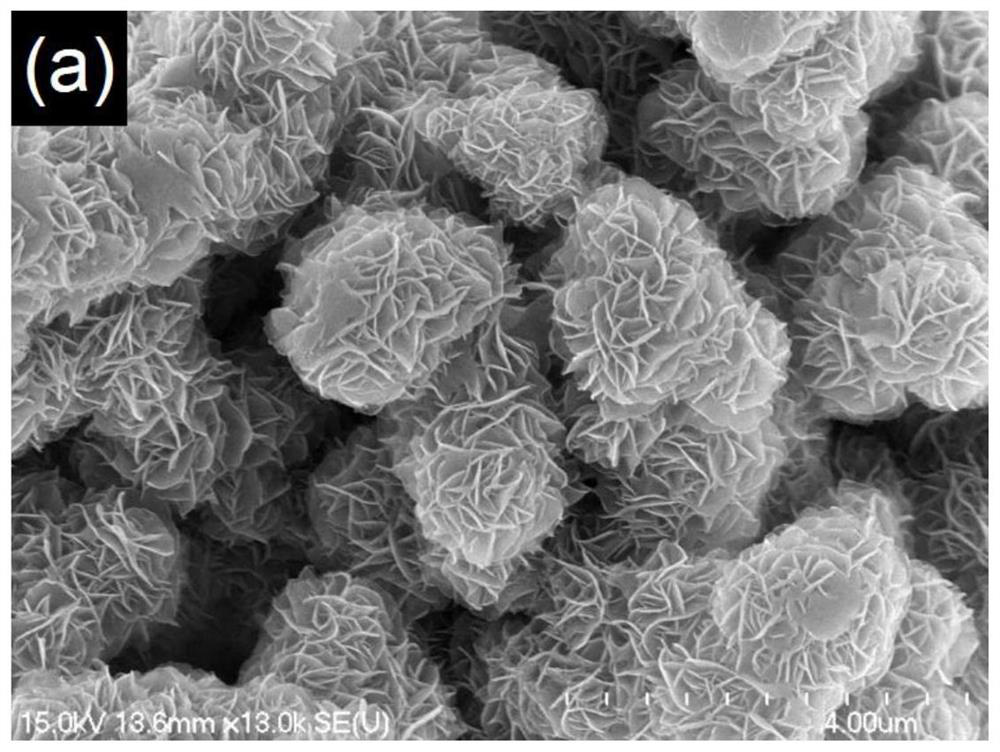

[0028] b) After mixing the zinc source, indium source and sulfur source in the presence of the second solvent, add the ZnFe obtained in step a) 2 o 4 nanofibers, subjected to solvothermal reaction, so that the resulting ZnIn 2 S 4 Nanosheets supported on ZnFe 2 o 4 On the nanofibers, a composite photocatalyst of indium zinc sulfide / zinc ferrite is obtained.

[0029] In the present invention, the iron source, zinc source and polyvinylpyrrolidone are firstly mixed in the presence of the first solvent, then electrospun, and then calcined to obtain ZnFe 2 o 4 Nanofibers. In the present invention, the iron source is preferably ferric ni...

Embodiment 1

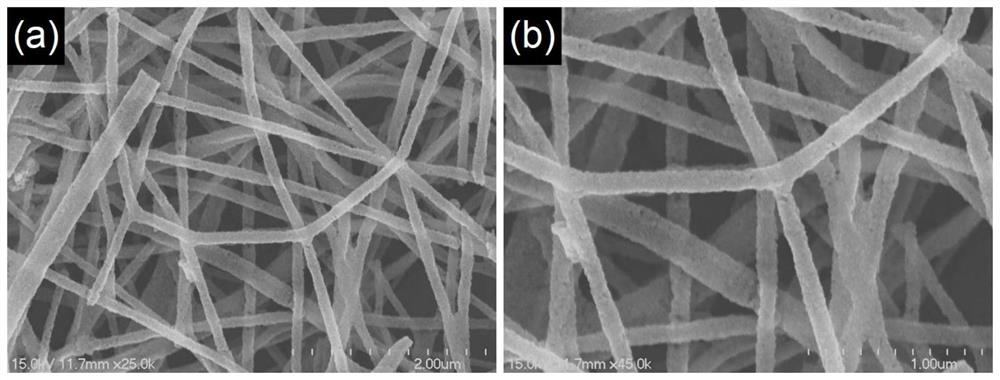

[0062] (1) ZnFe 2 o 4 Preparation of nanofibers: First, 2mmol of Zn(NO 3 ) 2 ·6H 2 O and 4mmol of Fe(NO 3 ) 3 9H 2 O was dissolved in 20 mL of DMF solution; after stirring at room temperature for 2 h, 4 g of polyvinylpyrrolidone (PVP, K90) was added above the solution, and the mixture was continuously magnetically stirred for 12 h to obtain a brown-red homogeneous precursor solution. Then, the precursor solution was transferred into a 5 mL plastic syringe equipped with a steel needle with a diameter of about 0.5 mm for electrospinning (voltage: 20 kV, injection rate: 0.2 mm / min). Finally, the obtained nanofibers were calcined in air at 600 °C for 2 hours at a heating rate of 1 °C / min to obtain ZnFe 2 o 4 Nanofibers.

[0063] Morphological characterization see figure 1 shown; figure 1 It is the ZnFe prepared in this embodiment 2 o 4 The scanning electron micrograph (SEM) of nanofiber, wherein (a) and (b) represent the ZnFe that the present embodiment prepares 2 o 4...

Embodiment 2

[0071] The preparation method provided in Example 1 is adopted, with the difference that: a ZIS / ZFO composite material with 10 wt% ZFO is obtained in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com