Preparation method of spherical porous iron oxide as well as product and application of spherical porous iron oxide

An iron oxide, spherical technology, applied in the manufacture of iron oxide, iron oxide/iron hydroxide, inductor/transformer/magnet, etc., can solve the problems of improving the structure of iron oxide, improve electromagnetic performance, simple preparation process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A preparation method of spherical porous iron oxide, comprising the following steps:

[0048] 1. Preparation of spherical iron oxide seed crystals

[0049] (1) Take the soluble iron salt of ferrous iron, and use pure water or deionized water to prepare an iron salt solution containing ferrous ions, and the concentration of ferrous ions is preferably controlled at 0.01~20g / L; The soluble ferrous salt preferably includes at least one of ferrous sulfate, ferrous nitrate and ferrous chloride, or a mixed solution of the three in any proportion.

[0050] (2) Take surfactant A and add it to the iron salt solution of step (1). The concentration of surfactant A is preferably controlled at 0.05~15g / L. Surfactant A includes thiourea, polyacrylamide , Tween, ethanol, ethylene glycol, isopropanol, n-butanol, EDTA, disodium EDTA, tetrasodium EDTA, polyvinyl alcohol at least one. If the ferrous salt solution contains impurities, it is necessary to remove impurities from the ferrous ...

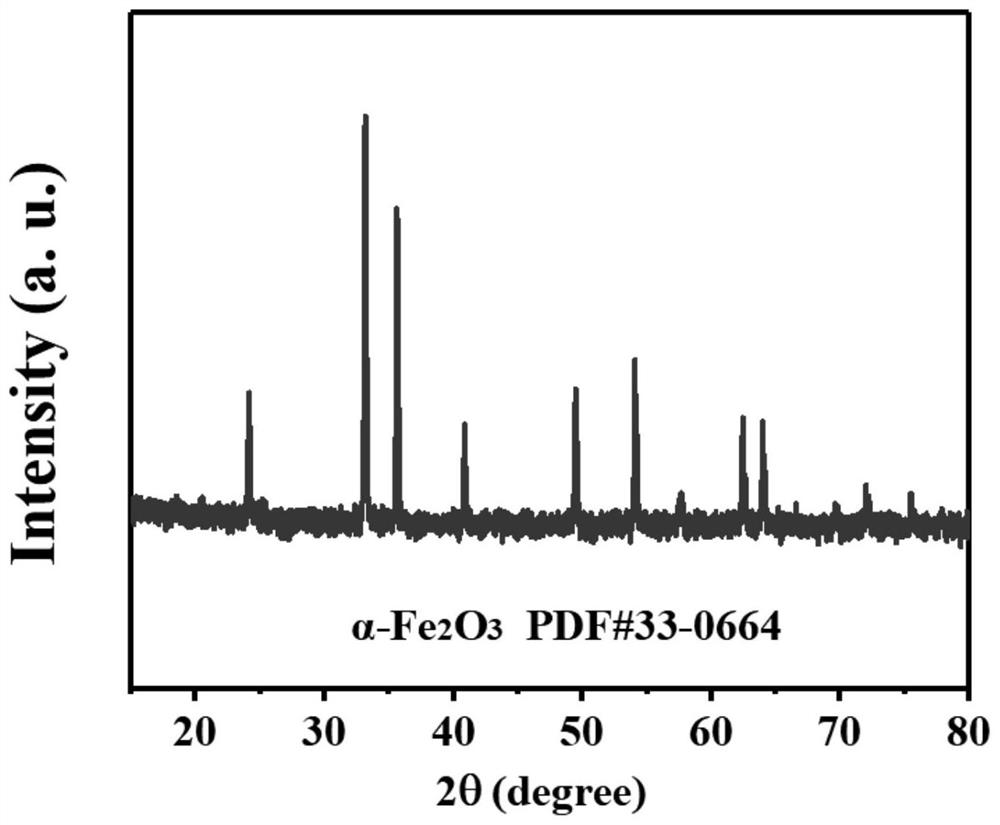

Embodiment 1

[0063] 1. Preparation of spherical iron oxide seeds

[0064] Use pure water to prepare 10L of ferrous sulfate solution with ferrous ion concentration of 5g / L, then weigh 10g of thiourea and add it to the ferrous sulfate solution and stir thoroughly; prepare 8L of 1mol / L sodium hydroxide solution with pure water , the prepared sodium hydroxide solution is slowly added to the ferrous sulfate solution, and the pH value is controlled to be 6; at the same time, air is introduced to oxidize the solution, and the amount of introduction is theoretically when ferrous iron is oxidized to ferric iron. Twice the amount of oxidant is required; heat the oxidized solution to 75°C, add 1L of ferrous sulfate solution with a ferrous iron content of 20g / L, fully stir, and keep warm for 1 hour to obtain spherical iron oxide seeds.

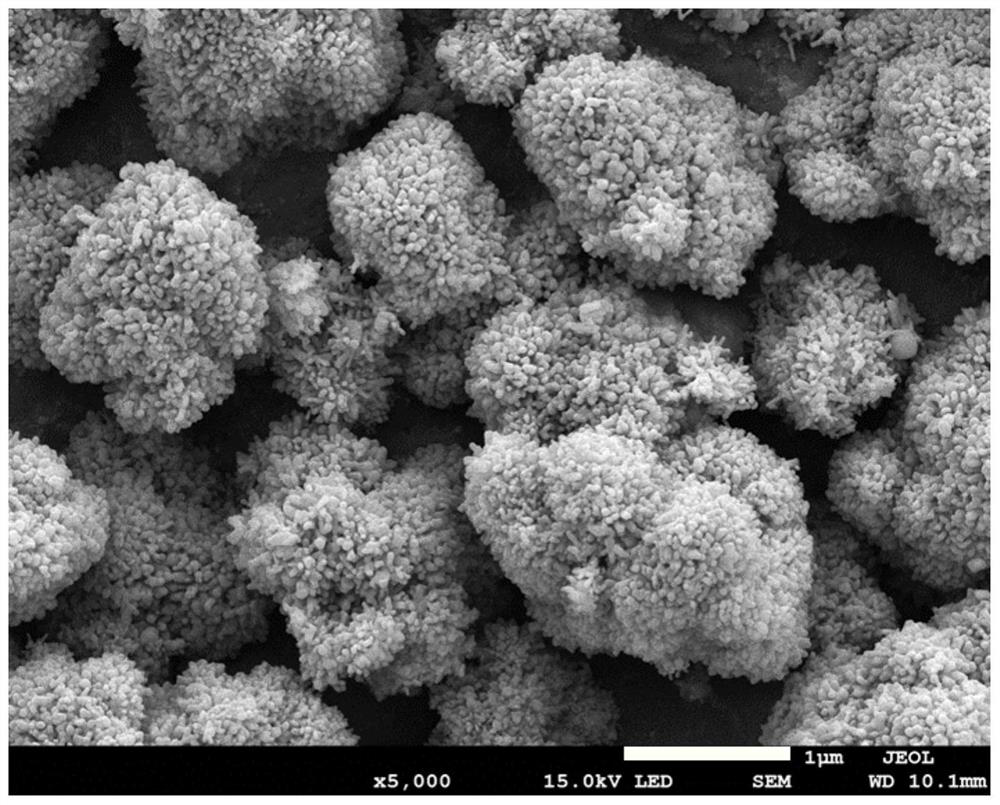

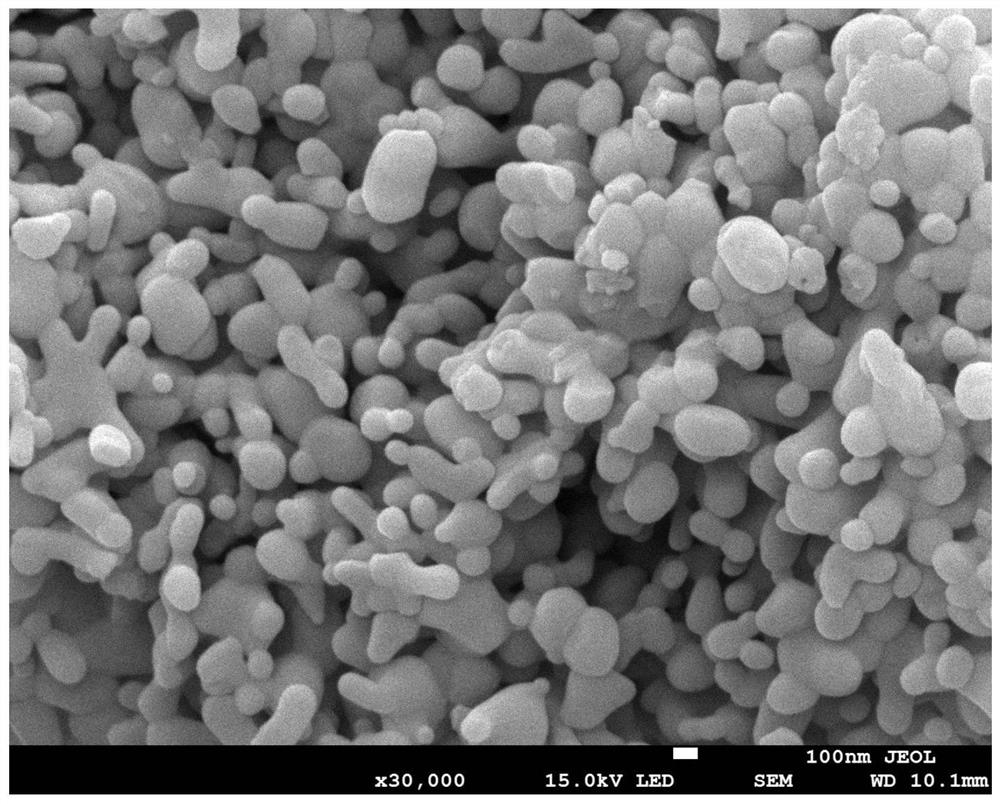

[0065] 2. Preparation of spherical porous iron oxide

[0066] Heat the above-mentioned spherical iron oxide seed crystal solution to 85°C; prepare 10L of a ferrous s...

Embodiment 2

[0069] 1. Preparation of spherical iron oxide seeds

[0070] Prepare 10L of ferrous sulfate solution with a ferrous ion concentration of 10g / L with pure water, then weigh 10g of EDTA and add it to the ferrous sulfate solution and fully stir; prepare 8L of 1mol / L sodium hydroxide solution with pure water, The prepared sodium hydroxide solution is slowly added to the ferrous sulfate solution, and the pH value is controlled at 4; at the same time, air is introduced to oxidize the solution, and the amount of introduction is theoretically required when ferrous iron is oxidized to ferric iron. 3 times the amount of oxidant; heat the oxidized solution to 80°C, add 1L of ferrous sulfate solution with a ferrous iron content of 30g / L, fully stir, and keep warm for 1h to obtain spherical iron oxide seeds.

[0071] 2. Preparation of spherical porous iron oxide

[0072] Heat the above-mentioned spherical iron oxide seed crystal solution to 90°C; use pure water to prepare 10L of ferrous su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com