Preparation method of ruthenium oxide for thick-film resistor

A technology of thick-film resistors and ruthenium oxide, which is applied in the field of powder metallurgy, can solve the problems of easy agglomeration of ruthenium oxide, poor performance of ruthenium oxide, and large pollution, and achieve the effects of simple preparation process, high yield and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

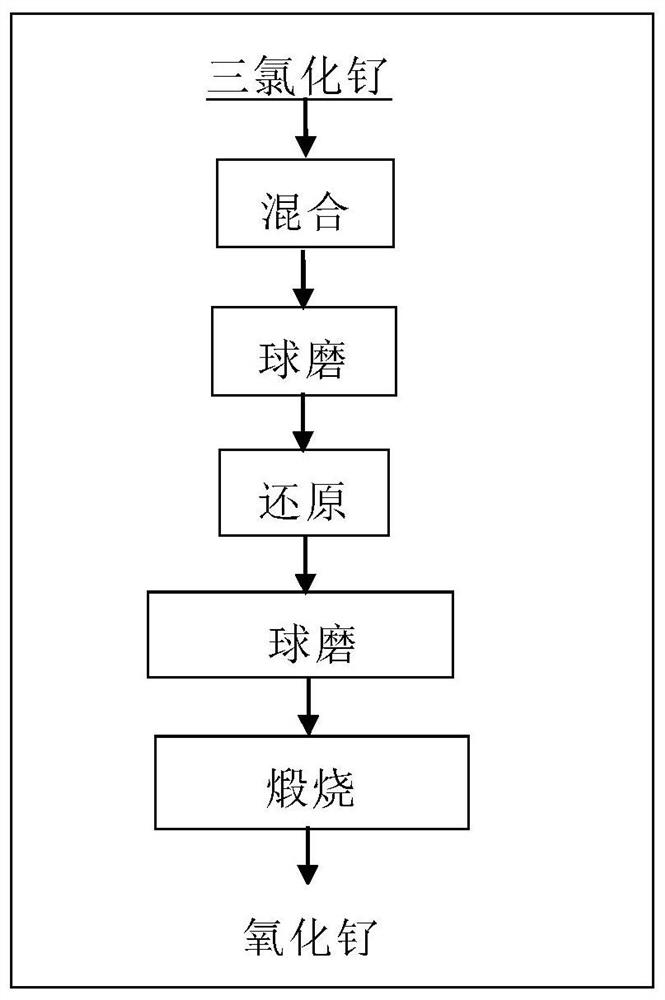

[0028] Such as figure 1 As shown, this embodiment includes the following steps:

[0029] Step 1, mix trichloride and ammonium chloride according to the mass ratio of 1:4 and then carry out ball milling, then place in a ball mill tank and ball mill for 2 hours at a speed of 500r / min, and transfer the obtained ball mill powder into a drying box at 120 Dry at ℃, then place in a ball mill jar and ball mill for 1 hour at a speed of 600r / min to obtain a mixed powder;

[0030] Step 2. Place the mixed powder obtained in Step 1 in a tube furnace, and heat it for 2 hours in a hydrogen atmosphere at a reduction temperature of 600° C. for calcination and reduction to obtain flake ruthenium powder;

[0031] Step 3, placing the flaky ruthenium powder obtained in step 2 in a ball mill jar at a speed of 800r / min for ball milling for 2h to obtain nano ruthenium powder;

[0032] Step 4. Place the nano-ruthenium powder obtained in step 3 in a tube furnace, and heat it for 2 hours in an air atm...

Embodiment 2

[0035] Such as figure 1 As shown, this embodiment includes the following steps:

[0036] Step 1, mix trichloride and ammonium chloride according to the mass ratio of 1:4 and then carry out ball milling, then place in a ball mill jar and ball mill for 3 hours at a speed of 400r / min, and transfer the obtained ball mill powder into a dry box at 150 Dry at ℃, then place in a ball mill jar and ball mill for 2 hours at a speed of 700r / min to obtain a mixed powder;

[0037] Step 2. Place the mixed powder obtained in Step 1 in a tube furnace, and heat it for 2 hours in a hydrogen atmosphere at a reduction temperature of 500° C. for calcination and reduction to obtain flake ruthenium powder;

[0038] Step 3, placing the flaky ruthenium powder obtained in step 2 in a ball mill jar at a speed of 800r / min for ball milling for 4h to obtain nano ruthenium powder;

[0039] Step 4. Place the nano-ruthenium powder obtained in step 3 in a tubular furnace, and heat it for 2 hours in an air atm...

Embodiment 3

[0042] Such as figure 1 As shown, this embodiment includes the following steps:

[0043] Step 1, mix trichloride and ammonium chloride according to the mass ratio of 1:4 and then carry out ball milling, then place in a ball mill jar and ball mill for 3 hours at a speed of 500r / min, and transfer the obtained ball mill powder into a drying box at 150 Dry at ℃, then place in a ball mill jar and mill at a speed of 700r / min for 1 hour to obtain a mixed powder;

[0044] Step 2. Place the mixed powder obtained in Step 1 in a tube furnace, and heat it for 4 hours in a hydrogen atmosphere at a reduction temperature of 700° C. for calcination and reduction to obtain flake ruthenium powder;

[0045] Step 3, placing the flaky ruthenium powder obtained in step 2 in a ball mill jar at a speed of 900r / min for ball milling for 3h to obtain nano ruthenium powder;

[0046] Step 4. Place the nanometer ruthenium powder obtained in step 3 in a tubular furnace, and heat it for 4 hours in an air a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com