Research method of silver selenide in copper anode slime refining

A technology of copper anode slime and silver selenide, applied in chemical instruments and methods, selenium/tellurium compounds, metal selenides/tellurides, etc., can solve the problem of lack of systematic research methods for the smelting thermodynamics of selenium-rich materials, Achieve reliable research methods and high-precision results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

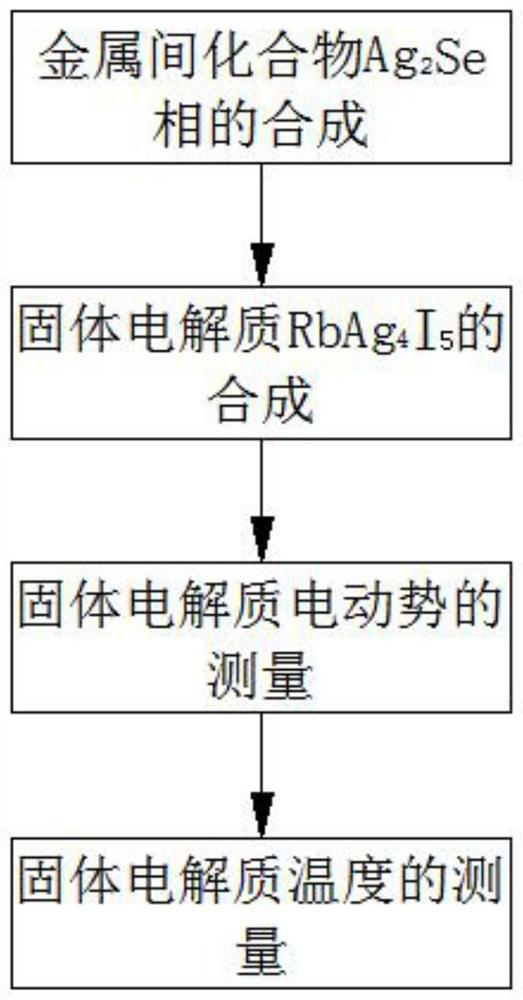

[0023] according to figure 1 As shown, the present embodiment provides a method for researching silver selenide in copper anode slime refining, comprising the following steps:

[0024] Step 1, intermetallic compound Ag 2 The synthesis of the Se phase, the purity is that 99.99% silver powder and the purity are that 99.999% selenium powder is mixed and sealed in the glass ampoule bottle of vacuum quartz according to the molar ratio of 2:1, then with the speed of 4K / min, the ampoule bottle is heated from room temperature to Store at 673K for two days, then heat the ampoule to 873K, keep it warm at this temperature for two days, and finally heat it to 1173K for one hour and then cool it to room temperature, and check the uniformity of the synthesized phase mixture by scanning electron microscopy and energy spectrometer , to obtain the intermetallic compound Ag 2 Se phase, and then under a pressure of 0.1GPa, use 1% excess amount of selenium atoms to grind the compound, and uni...

Embodiment 2

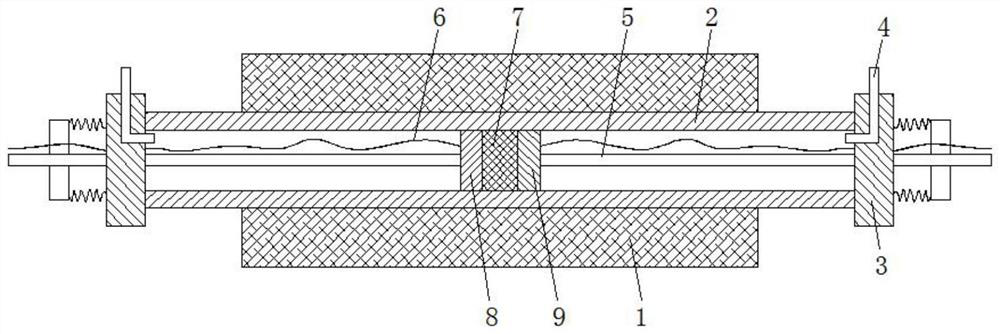

[0030] according to figure 2 As shown, the present embodiment provides the structure of a tubular furnace in the research method of silver selenide in the refining of copper anode slime, including a tubular furnace body 1, a quartz glass furnace tube 2, a sealing cover 3, and an inert gas inlet and outlet 4 , platinum resistance thermometer 5 and platinum wire 6, a quartz glass furnace tube 2 is arranged in the tubular furnace body 1, and a sealing cover 3 is provided at both ends of the quartz glass furnace tube 2, and the side of the sealing cover 3 is connected to the quartz glass furnace tube 2. The inert gas inlet and outlet 4, the sealing cover 3 is provided with a platinum resistance thermometer 5, and the quartz glass furnace tube 2 is provided with a platinum wire 6.

[0031] The middle part of the quartz glass furnace tube 2 is provided with a solid electrolyte 7, and the two sides of the solid electrolyte 7 are respectively provided with a sample system 8 and a ref...

Embodiment 3

[0033] The present embodiment provides the expansion of the research method of silver selenide in a kind of copper anode slime refining, in the embodiment 1, the solid electrolyte when solid pure silver and selenium form silver selenide is measured, and its reaction is by formula (1) Given, the actual reaction of the electrochemical cell is the electromotive force of the cell

[0034] 2Ag(s)+Se(s)=Ag 2 Se(s) (1)

[0035] (-)Pt∣Ag(s)∣RbAg 4 I 5 (s)∣Ag 2Se(s), Se(s,l)∣Pt(+)

[0036] In the temperature range of 350K-500K and under the ambient atmospheric pressure, in addition to the volume expansion work, the Gibbs energy change of the cell body reaction is related to the reversible electromotive force of the reaction (1), according to the Nentes equation

[0037]

[0038] In the formula, E is the electromotive force generated by the battery, and F is the Faraday constant 96485C.mol -1 , the number of potential changes transferred in the battery reaction is z=2. It can ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com