Saccharomyces cerevisiae SWGCJM001 as well as culture method and application thereof

A technology of Saccharomyces cerevisiae and its cultivation method, which is applied in the field of Saccharomyces cerevisiae SWGCJM001 and its cultivation, can solve the problems of low xylose purity, high reaction pressure, and inability to meet industrial production, and achieve economic benefits, mild reaction conditions, and good industrial production. The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

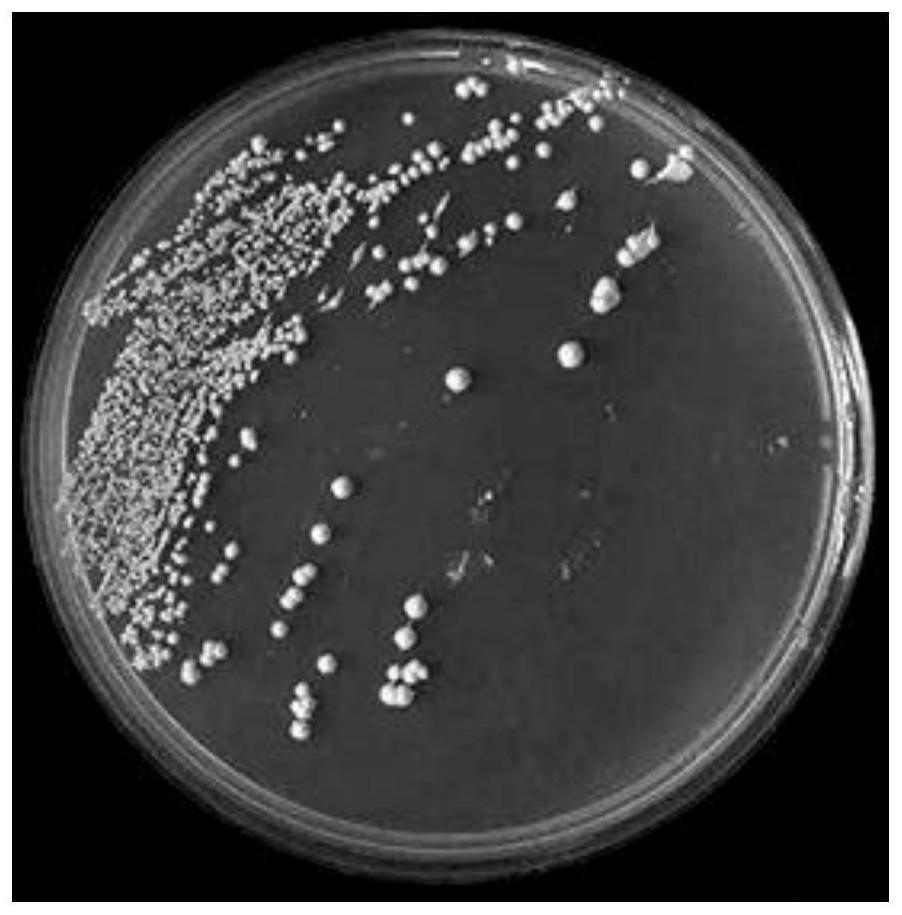

[0047] Isolation, Screening and Identification of Saccharomyces cerevisiae SWGCJM001

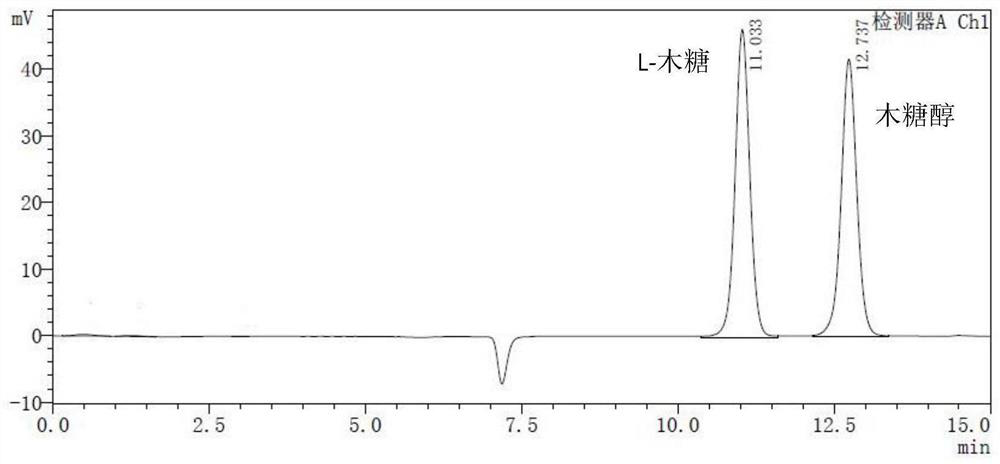

[0048] The soil samples randomly collected from the farmland were diluted with sterile water at 1:100 (W / V), and spread on the screening plate medium. The screening plate medium (pH 7.0) included: 1% potassium dihydrogen phosphate, 0.3 % diammonium hydrogen phosphate, 0.5% yeast extract, 1% tryptone, 5% xylitol, 15% agar. Cultivate at 30°C for 48h, then select a single colony and inoculate them into the liquid selection medium, and culture at 30°C and 200rpm for 48h. After the culture was centrifuged at 8000rpm for 10min, the cells were added to the reaction liquid for reaction. The reaction liquid included 5% xylitol, pH 7.0 and 50mM potassium phosphate buffer, and reacted at 250rpm at 30°C for 24h. After the reaction liquid was centrifuged at 12000 rpm, it was detected by liquid phase high performance chromatography (HPLC).

[0049] The HPLC detection conditions are: column: Aminex HPX-8...

Embodiment 2

[0053] Fermentation of Saccharomyces cerevisiae SWGCJM001

[0054] Seed medium: 5% glucose, 0.5% yeast extract, 0.2% (NH 4 ) 2 SO 4 , 0.2% KH 2 PO 4 , 0.1% MgSO 4 ·7H 2 O, the pH value is 5.5; fermentation medium: 15% glucose, 0.2% yeast extract, 0.2% (NH 4 ) 2 SO 4 , 0.1% KH 2 PO 4 , the solvent is distilled water, and the pH value is adjusted to 5.5. The seed medium was sterilized at 115° C. for 25 minutes, inoculated after cooling, and cultured in shake flasks with a liquid volume of 30%.

[0055] Specific cultivation steps: take the bacteria stored at -70°C and draw a line on the seed solid plate, pick a single colony and inoculate it in the seed liquid medium, cultivate it at 30°C and 250rpm for 12 hours, and inoculate the seeds according to the inoculation amount of 5%. Inoculated in the fermentation medium, 30°C, 250rpm shaking culture for 24 hours, after the cultivation, the fermentation broth was centrifuged and washed twice with saline, and the wet bacter...

Embodiment 3

[0057] Production of L-xylose

[0058] In a 10L catalytic system, add 600g of xylitol, use pH7.0 phosphate buffer solution as the buffer, stir, add 10g of Saccharomyces cerevisiae SWGCJM001 strain, and start the reaction. After the reaction at 35° C. for 12 hours, the concentration of L-xylose in the solution can reach 44.79 g / L as detected by liquid chromatography, and the conversion rate can reach more than 96.54%. After the reaction, the reaction liquid was treated by membrane filtration, separated and purified, concentrated and crystallized, centrifuged and dried to obtain 427.72 g of finished product. After testing, the chiral purity of the finished L-xylose is 100%, the product purity is 99.90%, and the product yield is 95.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com