Porous titanium-based carbon nanotube reinforced amorphous metal oxide coating electrode and preparation method thereof

A technology of oxide coating and carbon nanotubes, which is applied in the field of electrodes, can solve the problems of low internal energy, viscosity coefficient force and specific surface area, etc., and achieve the effects of good electrochemical stability, uniform distribution, and reduced internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

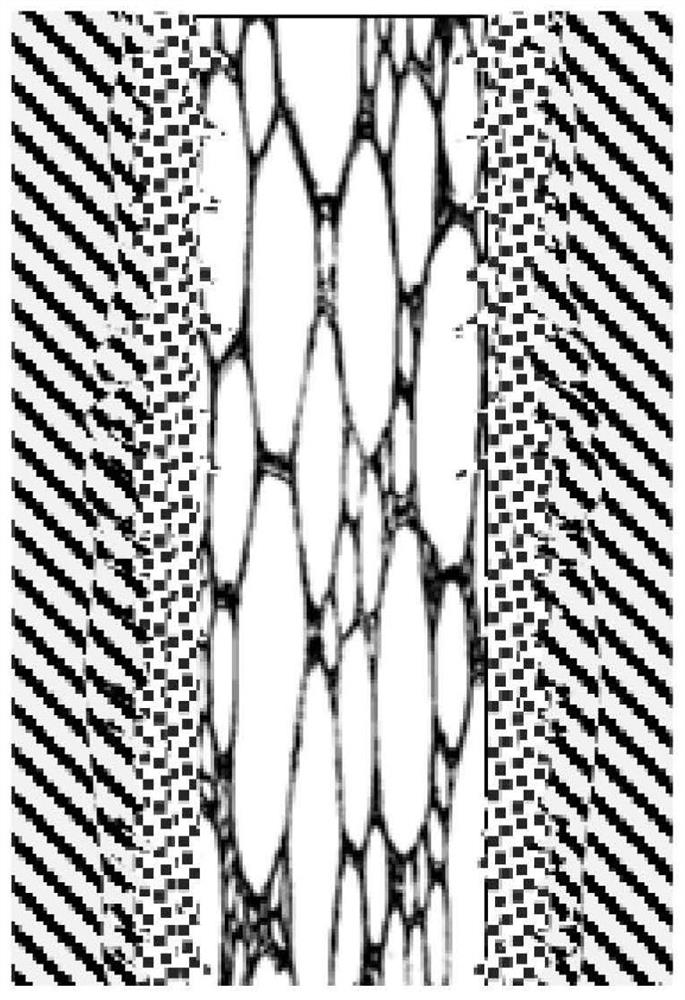

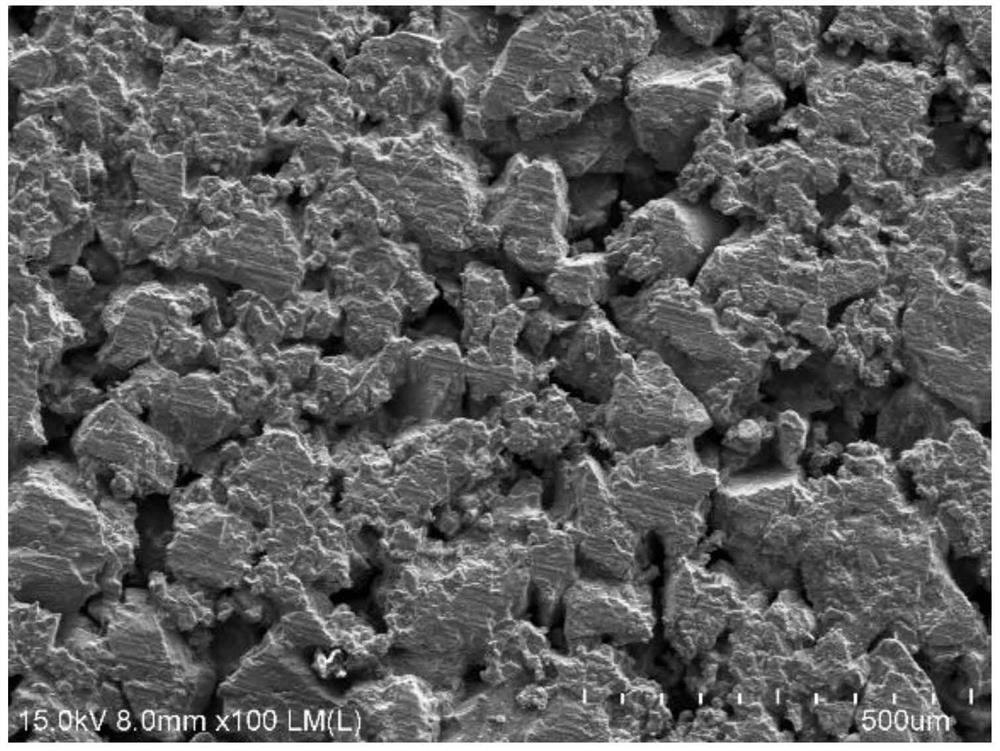

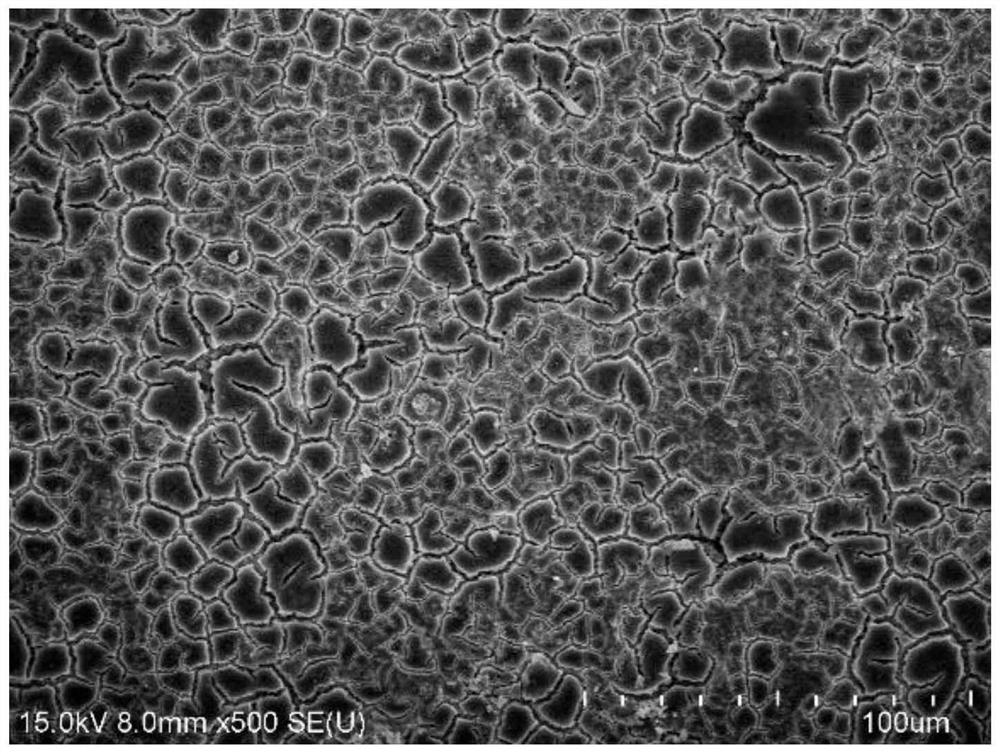

[0034] Embodiment 1: a kind of porous titanium-based carbon nanotube reinforced amorphous metal oxide coating electrode (see figure 1 ), including a porous titanium substrate, a conductive metal oxide intermediate layer and an amorphous metal active layer arranged sequentially from the inside to the outside, and the conductive metal oxide intermediate layer is Sn-Ru-Ti-TaO prepared by thermal decomposition x layer, the amorphous metal active layer is a carbon nanotube reinforced Mn-Mo-Ni-ZrOx oxide layer obtained by pulse electrodeposition and thermal oxidation treatment;

[0035] The total thickness of the composite electrode material is 2.5mm, the thickness of the porous titanium matrix is 2mm, the pore diameter of the porous titanium matrix is 20μm, and the pore depth is 5-10μm; Sn-Ru-Ti-TaO x The molar ratio of Sn, Ru, Ti and Ta in the layer is 8:2:1:1, and the thickness is 50 μm; the molar ratio of Mn, Mo, Ni and Zr in the carbon nanotube reinforced Mn-Mo-Ni-ZrOx oxid...

Embodiment 2

[0044] Embodiment 2: The porous titanium-based carbon nanotube-reinforced amorphous metal oxide coating electrode of this embodiment is basically the same as that of Embodiment 1, except that the total thickness of the composite electrode material is 6mm, and the thickness of the porous titanium matrix is 5mm, the pore diameter of the porous titanium substrate is 30μm, and the pore depth is 10-30μm; Sn-Ru-Ti-TaO x The molar ratio of Sn, Ru, Ti and Ta in the layer is 10:2:2:1, and the thickness is 80 μm; the molar ratio of Mn, Mo, Ni and Zr in the carbon nanotube reinforced Mn-Mo-Ni-ZrOx oxide layer is 6:3:2:1, the thickness is 420μm;

[0045] The preparation method of porous titanium-based carbon nanotube reinforced amorphous metal oxide coating electrode comprises the following specific steps:

[0046] (1) Use 60-mesh SiC to sandblast the porous titanium substrate to remove the oxide layer on the surface of the porous titanium substrate, then place the porous titanium substr...

Embodiment 3

[0052] Embodiment 3: The porous titanium-based carbon nanotube-reinforced amorphous metal oxide coating electrode of this embodiment is basically the same as that of Embodiment 1, except that the total thickness of the composite electrode material is 11.4mm, and the thickness of the porous titanium substrate 10mm, the pore diameter of the porous titanium substrate is 50μm, and the pore depth is 20-40μm; Sn-Ru-Ti-TaO x The molar ratio of Sn, Ru, Ti and Ta in the layer is 12:3:2:1, and the thickness is 100 μm; the molar ratio of Mn, Mo, Ni and Zr in the carbon nanotube reinforced Mn-Mo-Ni-ZrOx oxide layer is 8:4:2:1, the thickness is 600μm;

[0053] The preparation method of porous titanium-based carbon nanotube reinforced amorphous metal oxide coating electrode comprises the following specific steps:

[0054] (1) Using 100 mesh Al 2 o 3 Sand blast the porous titanium substrate to remove the oxide layer on the surface of the porous titanium substrate, then place the porous ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com